Fly ash recycling device with built-in glass film removing function

A technology of fly ash and glass film, applied in transportation and packaging, chemical instruments and methods, solid waste removal, etc., can solve the problem of ensuring stability, durability, large capacity, lack of processing efficiency, and huge consumption that have not yet been proposed Investment costs and maintenance costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement the present invention.

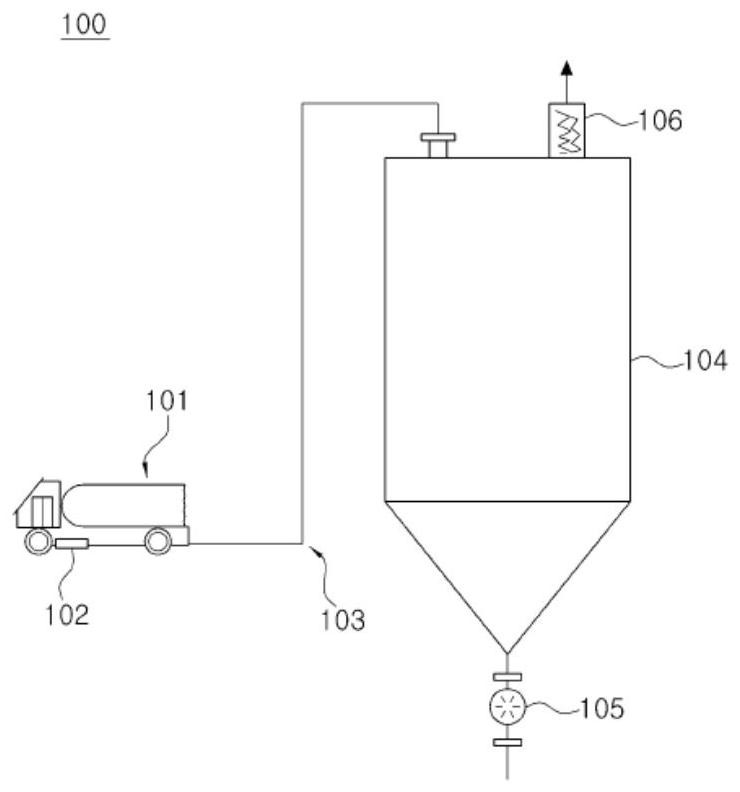

[0108] figure 1 It is a system diagram showing the fly ash recycling device with built-in glass film removal function of the present invention.

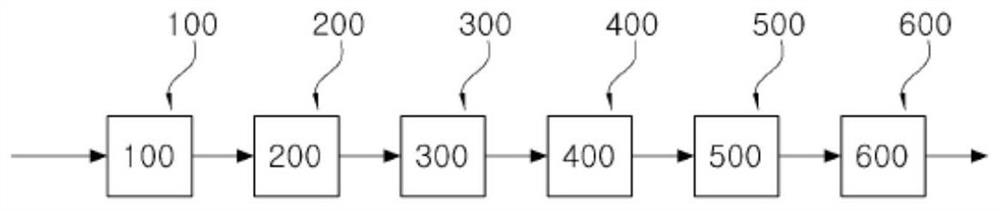

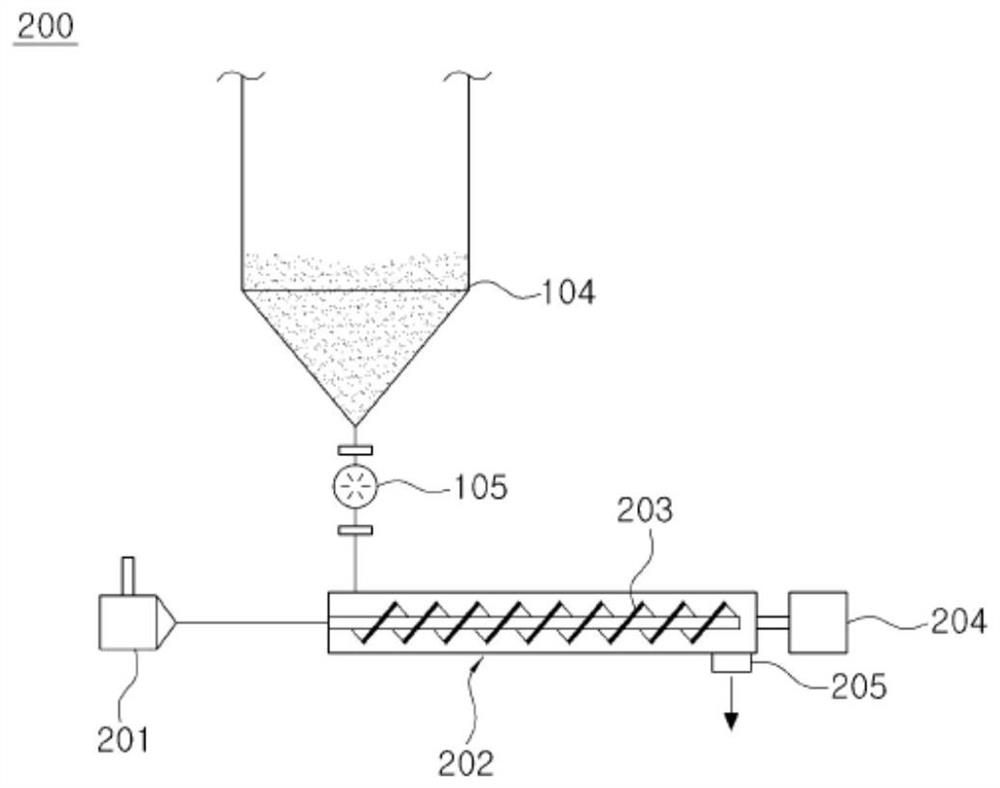

[0109] refer to figure 1 , the fly ash recycling device with built-in glass film removal function includes a first storage tank 100 , a feeder 200 , an unburned carbon removal unit 300 , a glass film removal unit 400 , a second storage tank 500 , and a control panel 600 .

[0110] The above-mentioned first storage tank 100 is set at the rear end of the boiler of the thermal power plant. After the coal is burned in the boiler and discharged from the exhaust gas, the fly ash collected by the electrostatic precipitator is separated according to the specified particle size, The air pressurized by the tank truck 101 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com