Concrete retarder and preparation method thereof

A concrete and retarder technology, which is applied in the field of building materials, can solve the problems of small reduction, lower reaction heat, and affect the anti-scouring performance of concrete, and achieve the effects of inhibiting hydration, improving compatibility, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

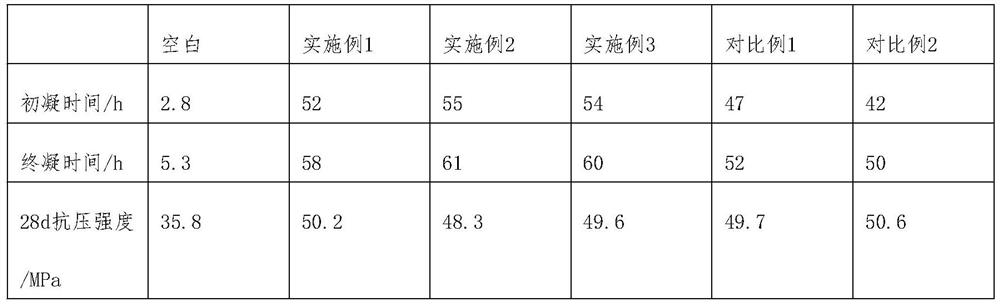

Examples

Embodiment 1

[0024] A concrete retarder, made of the following raw materials: 3 parts of modified microcrystalline cellulose, 3 parts of acrylic acid, 6 parts of modified glass fiber, 10 parts of borax, 6 parts of polyvinyl chloride resin, 4 parts of anhydrous sodium sulfate , 3 parts of quartz sand, 12 parts of sodium tripolyphosphate, 1 part of carboxymethyl cellulose.

[0025] The preparation of the modified microcrystalline cellulose is as follows: adding the microcrystalline cellulose to an 80% ethanol solution whose mass is 10 times that of the microcrystalline cellulose, adding sodium hydroxide with 10% mass of the microcrystalline cellulose and stirring at 45-50°C for 6 hours After cooling, add 20% carboxymethyl cellulose of microcrystalline cellulose, and stir at 30-35°C for 2 hours to obtain a modified coarse material; dry the modified coarse material to obtain a modified microcrystalline Crystalline cellulose.

[0026] The preparation of the modified glass fiber is as follows: ...

Embodiment 2

[0034] A concrete retarder, made from the following raw materials: 5 parts of modified microcrystalline cellulose, 2 parts of acrylic acid, 6.5 parts of modified glass fiber, 6 parts of borax, 8 parts of polyvinyl chloride resin, 3 parts of anhydrous sodium sulfate , 4 parts of quartz sand, 10 parts of sodium tripolyphosphate, 1 part of carboxymethyl cellulose.

[0035] The preparation of the modified microcrystalline cellulose is as follows: adding the microcrystalline cellulose to an 80% ethanol solution whose mass is 10 times that of the microcrystalline cellulose, adding sodium hydroxide with 10% mass of the microcrystalline cellulose and stirring at 45-50°C for 6 hours After cooling, add 20% carboxymethyl cellulose of microcrystalline cellulose, and stir at 30-35°C for 2 hours to obtain a modified coarse material; dry the modified coarse material to obtain a modified microcrystalline Crystalline cellulose.

[0036] The preparation of the modified glass fiber is as follow...

Embodiment 3

[0044] A concrete retarder, made of the following raw materials: 6 parts of modified microcrystalline cellulose, 1 part of acrylic acid, 8 parts of modified glass fiber, 5 parts of borax, 10 parts of polyvinyl chloride resin, 2 parts of anhydrous sodium sulfate , 5 parts of quartz sand, 8 parts of sodium tripolyphosphate, 3 parts of carboxymethyl cellulose.

[0045] The preparation of the modified microcrystalline cellulose is as follows: adding the microcrystalline cellulose to an 80% ethanol solution whose mass is 10 times that of the microcrystalline cellulose, adding sodium hydroxide with 10% mass of the microcrystalline cellulose and stirring at 45-50°C for 6 hours After cooling, add 20% carboxymethyl cellulose of microcrystalline cellulose, and stir at 30-35°C for 2 hours to obtain a modified coarse material; dry the modified coarse material to obtain a modified microcrystalline Crystalline cellulose.

[0046] The preparation of the modified glass fiber is as follows: m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com