Mixed spinel type black ceramic pigment and preparation method thereof

A black ceramic and spinel-type technology, applied in the field of ceramic pigments, can solve the problems of the precipitation mechanism of colored spinel, achieve good coloring performance, pure color, and reduce uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

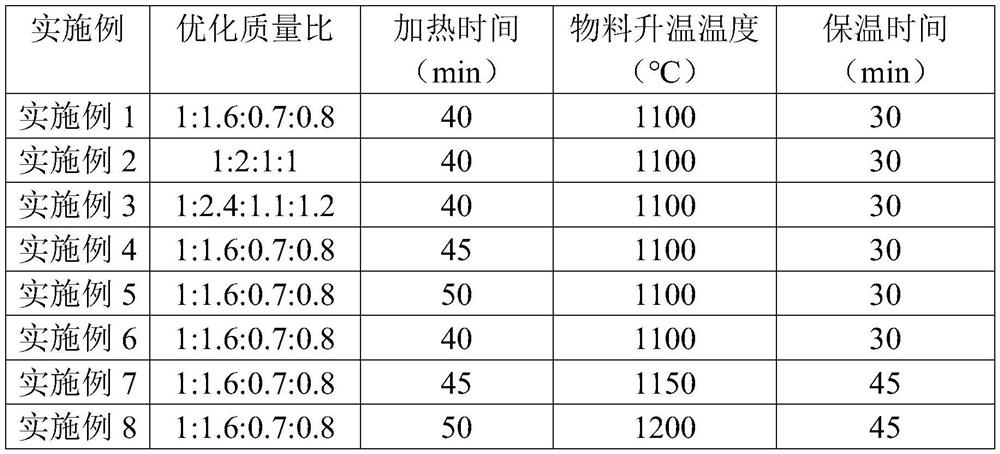

[0027] The invention provides a kind of preparation method of mixed spinel type black ceramic pigment, comprises the steps:

[0028] S1, using the thermodynamic database software, set the predetermined simulation conditions, the Fe of the predetermined raw material ratio 2 o 3 -Cr 2o 3 The solidification process of -MnO-NiO system is simulated and calculated, and the Fe is optimized and determined according to the phase composition and color performance in the simulation results. 2 o 3 -Cr 2 o 3 - the mass fractions of the four raw material components in the MnO-NiO system to obtain Fe 2 o 3 -Cr 2 o 3 - The optimal mass ratio of the MnO-NiO system is 1:(1.6-2.4):(0.7-1.1):(0.8-1.2);

[0029] S2, according to the Fe described in step S1 2 o 3 -Cr 2 o 3 -Optimized mass ratio of the MnO-NiO system, the Fe 2 o 3 、Cr 2 o 3 The four raw material powders of , MnO and NiO are prepared in proportion, and then mixed evenly to obtain a mixed material;

[0030] S3, unde...

Embodiment 1

[0041] A kind of preparation method of mixed spinel type black ceramic pigment:

[0042] S1, using Factsage7.0 simulation calculation to obtain the optimal proportion range, the specific process of simulation calculation is as follows:

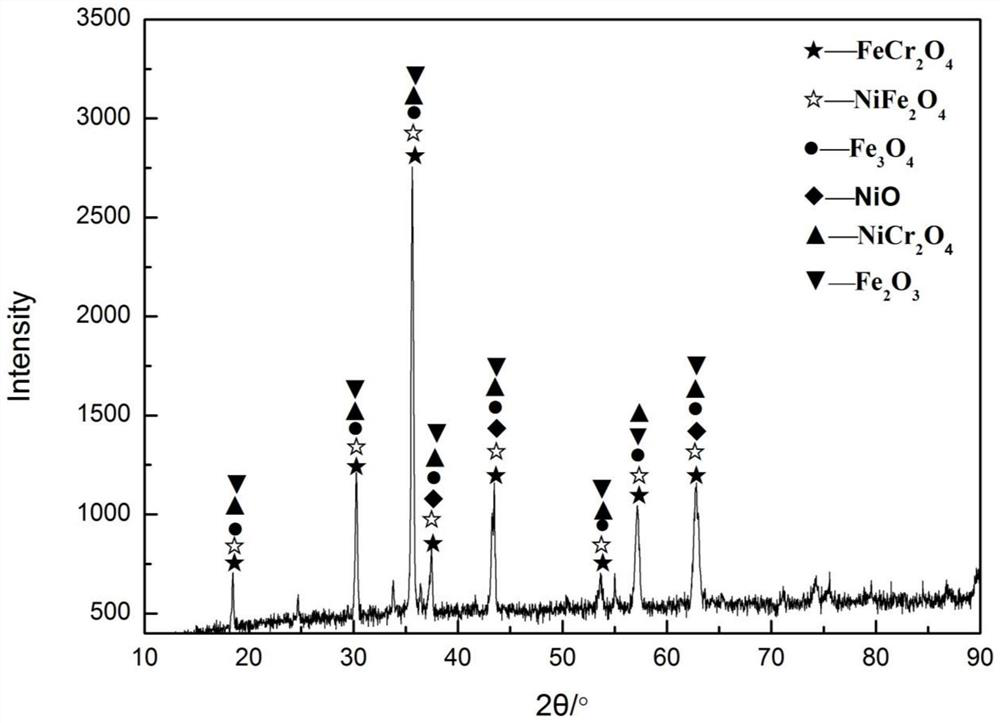

[0043] Using the Equilib module of FactSage7.0 to calculate Fe 2 o 3 -Cr 2 o 3 -Phase composition and spinel content of MnO-NiO system at different mass ratios;

[0044] 1) Databases: FactPS and FToxid.

[0045] 2) Types of compounds: gases and pure solids.

[0046] 3) Solid solution settings: FToxid-SLAGA, FToxid-SPANA.

[0047] 4) The simulation calculation conditions are: the initial solidification temperature is set to 2250 °C, the calculation temperature interval is 100 °C, the simulation calculation process ends when the target phase FToxid-SLAGA completely disappears, the system pressure is set to 1 atm, and the optimal ratio is calculated. way to export and further process in Origin software.

[0048] Fe was obtained by simulat...

Embodiment 2

[0054] The difference with Example 1 is: the optimal mass ratio is set to 1:2:1:1, namely Fe 2 o 3 3.0g, Cr 2 o 3 6.0g, MnO 3.0g, and NiO 3.0g, and other steps are the same as in Example 1, and will not be repeated here.

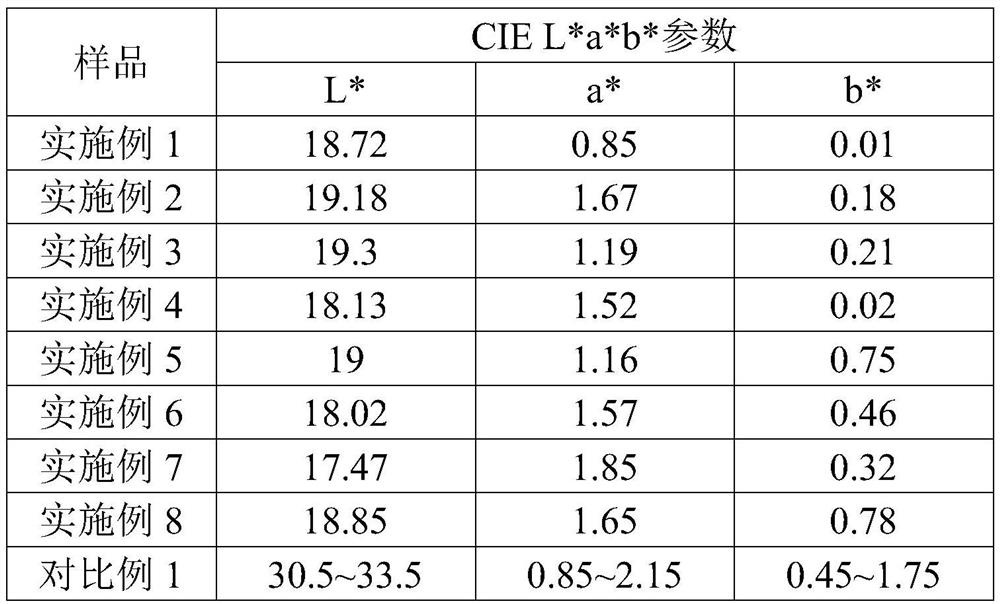

[0055] The CIE parameters of the prepared black ceramic pigment were tested, and the result was that the L value was 19.18, the a value was 1.67, and the b value was 0.18, indicating that the black ceramic pigment prepared in this example had high blackness and good color rendering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com