Core-shell quantum dot and preparation method thereof, quantum dot film and light emitting diode

A core-shell quantum dot and core-quantum technology, applied in the fields of core-shell quantum dots and their preparation, quantum dot films and light-emitting diodes, can solve the problem that optical stability cannot meet the requirements of material performance stability, and achieve high stability , low toxicity, high controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing core-shell quantum dots, comprising the following steps:

[0045] S1, providing InP nuclear quantum dot solution;

[0046] S2, adding the InP nuclear quantum dot solution to the zinc precursor mixed solution to obtain the first reaction solution, the zinc precursor mixed solution includes the first zinc carboxylate precursor with a carbon chain length of 2 to 6 and a carbon chain length of 10-22 second zinc carboxylate precursor;

[0047] S3, adding a first anion precursor to the first reaction solution, the first anion precursor is a selenium precursor or a selenium-sulfur mixed precursor, and the second reaction solution is formed after the reaction, and the selenium-sulfur mixed precursor Se: S≥1:1;

[0048] S4, adding a second anion precursor to the second reaction solution, where the second anion precursor is a sulfur precursor, to obtain the core-shell quantum dots.

[0049] The present invention uses the mixed zinc...

Embodiment 1

[0055] Embodiment 1: the synthesis of InP nuclear quantum dot solution

[0056] 1) Add 0.58g of indium acetate (In(Ac) 3 , 2mmol), myristic acid 1.37g (MA, 6mmol), octadecene 50g (ODE) were weighed in turn and placed in a 250mL three-necked flask, and a magnet was added, nitrogen gas was passed, and the temperature of the system was raised to 170°C. Stirring speed 60rpm / min;

[0057] 2) Cool down to 50°C, inject 1mL P(TMS) 3 For the precursor, heat up to 290°C and react for 5 minutes until the position of the first exciton peak reaches 420-430nm;

[0058] 3) Cool down to 230°C, add TMSP precursor dropwise at a rate of 20mL / h, take a sample and monitor after adding for 5 minutes, and stop the reaction after the first UV exciton peak reaches the position of 450nm, 475nm, 495nm, 570nm, 600nm and 650nm respectively , to obtain InP nuclear quantum dot solution.

[0059] The resulting InP nuclear quantum dot solution can be further purified:

[0060] 4) Pour the prepared InP ...

Embodiment 2

[0063] Embodiment 2: Synthesis of core-shell quantum dots

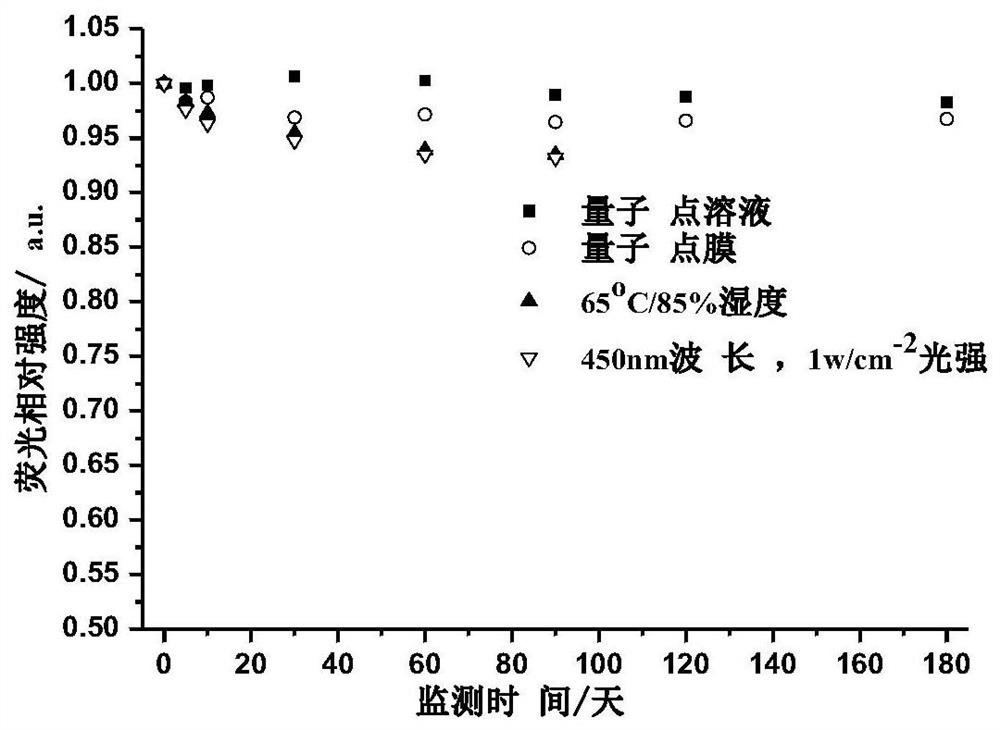

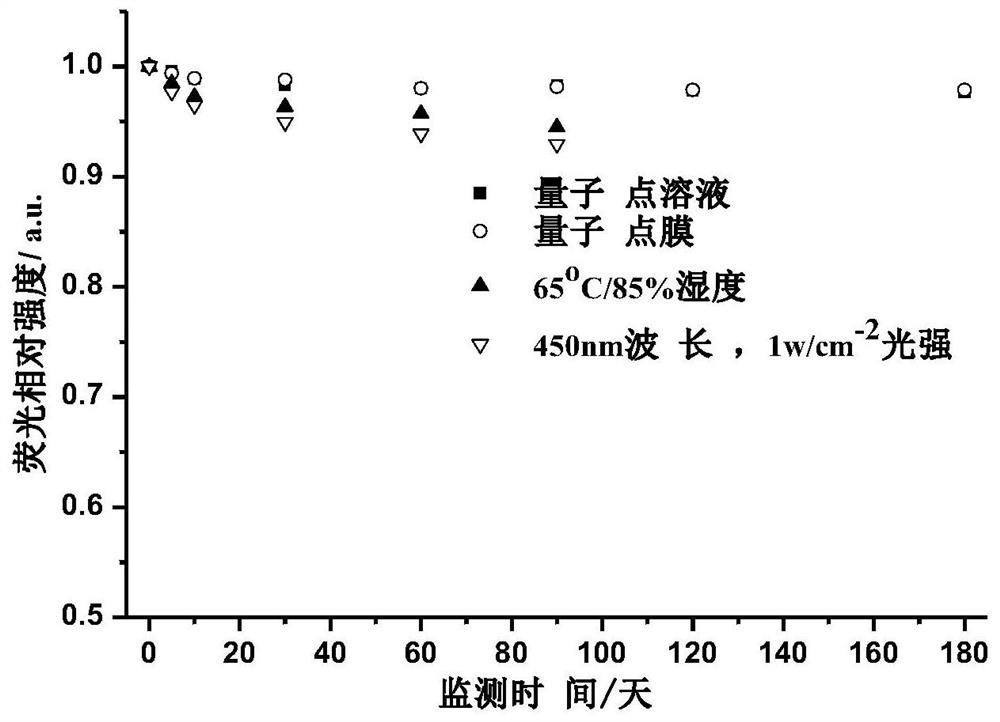

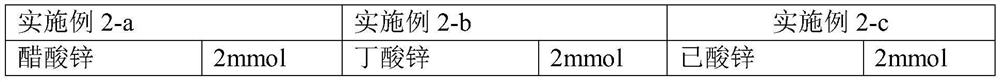

[0064] The raw material formula of embodiment 2 and the partial properties of the obtained core-shell quantum dots are shown in the following table:

[0065] Table 1 Example 2 Raw material formula and core-shell quantum dot properties

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com