Method for detecting photoelectric property of microcell of a photoelectric material

A technology of optoelectronic materials and optoelectronic properties, applied in the field of photoelectrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

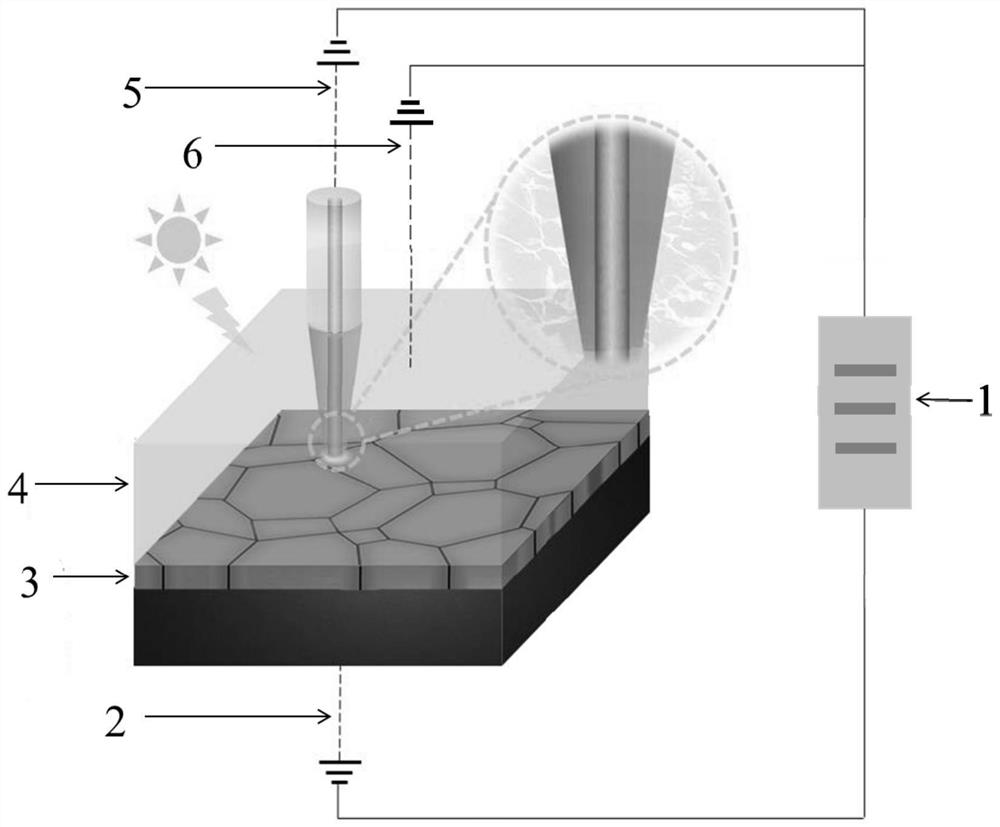

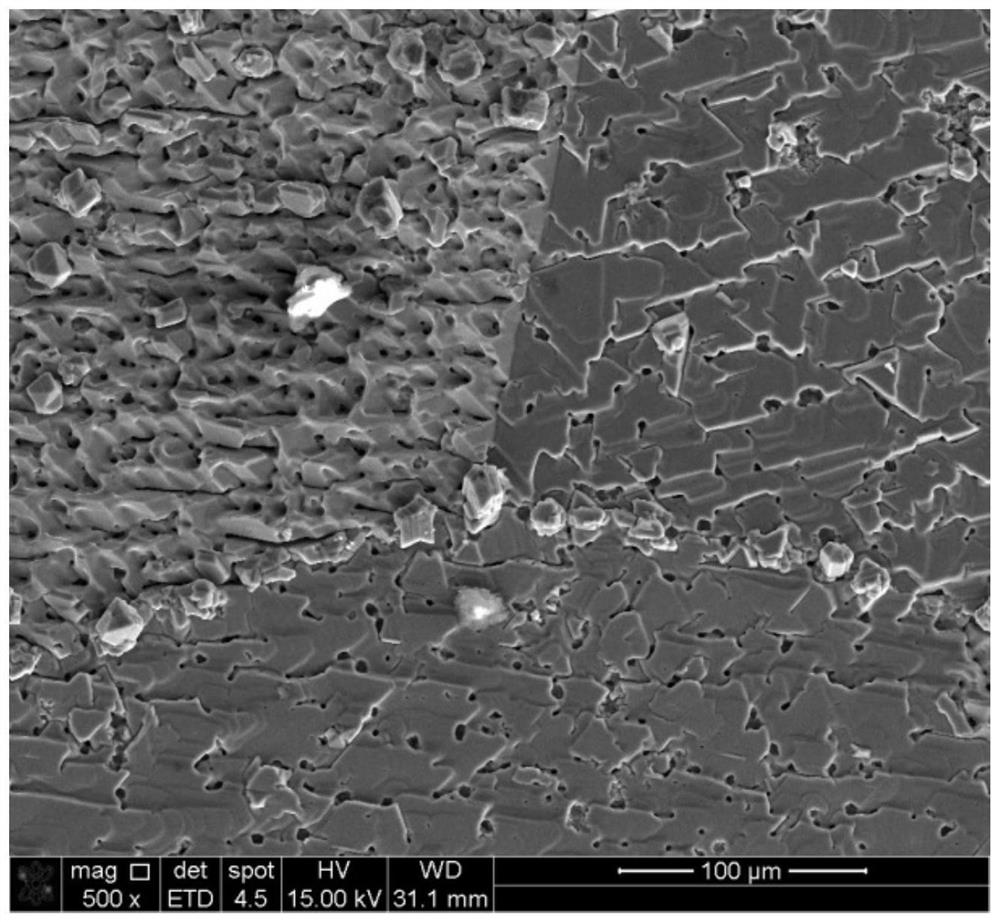

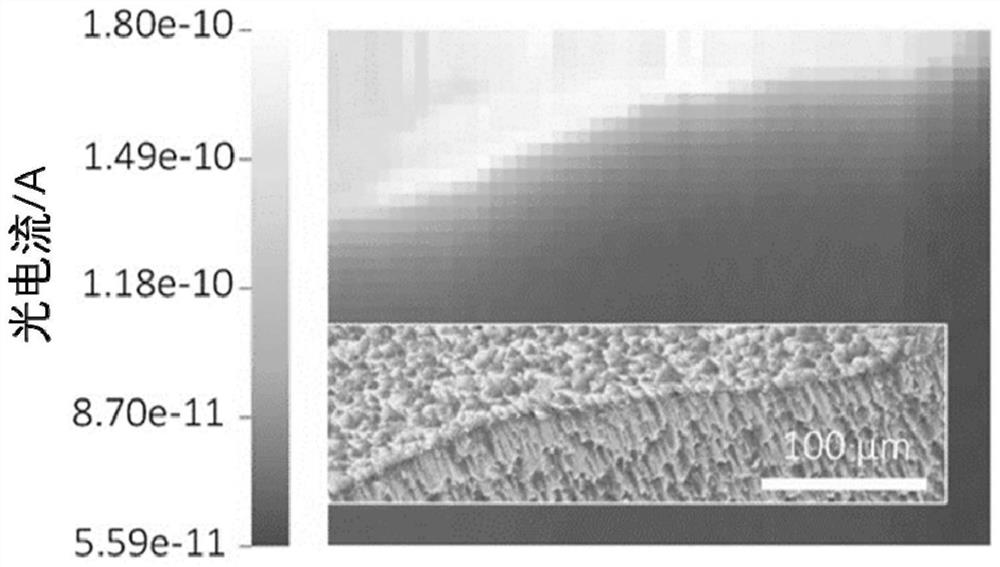

[0034] Acetonitrile solution and 0.1 mol / L tetrabutylammonium hexafluorophosphate are configured as supporting electrolyte, 0.05 mol / L ferrocene is redox agent, in the photoelectrochemical reaction solution containing oxidation or reducing agent as mentioned above , the polysilicon film material to be measured is fixed on the bottom of the photoelectrochemical reaction zone 4, the microelectrode probe 5 (platinum electrode, 3 μm in diameter) is used as the working electrode, and silver / silver nitrate is the reference electrode 6. The polysilicon to be measured The membrane material is the counter electrode 2, which constitutes a photoelectrochemical test cell. The microelectrode probe 5 is connected with the scanning electrochemical microscope control system 1 to form a precise control scanning mobile platform, and the movement is precisely controlled by the scanning electrochemical microscope so that the microelectrode probe 5 is close to the surface of the photoelectric film ...

Embodiment 2

[0036]Acetonitrile and 0.1 mol / liter tetrabutylammonium hexafluorophosphate are configured as supporting electrolyte, 0.05 mol / liter ferrocene is used as redox agent, silver / silver nitrate electrode is selected as reference electrode 6, and platinum electrode is used as counter electrode. The electrode 2, the platinum wire is the working electrode 7, and the optical fiber with a diameter of 3 microns is the optical fiber microprobe 8. The polysilicon film material to be measured is fixed on the bottom of the photoelectrochemical reaction zone 4, and the three-electrode system in the scanning electrochemical microscope system is sequentially connected with the silver / silver nitrate reference electrode 6, the platinum counter electrode 2, and the polysilicon film material working electrode 7 connected. At the same time, the optical fiber microprobe 8 is connected with the scanning electrochemical microscope control system 1 to form a precisely controlled scanning mobile platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com