Method for oxidative degradation of sulfide in industrial wastewater through combined hydrogen peroxide-bleaching powder

A technology of oxidative degradation and industrial wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of high process cost, hidden safety hazards in transportation and storage, and achieve easy availability of raw materials and easy operation. , the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

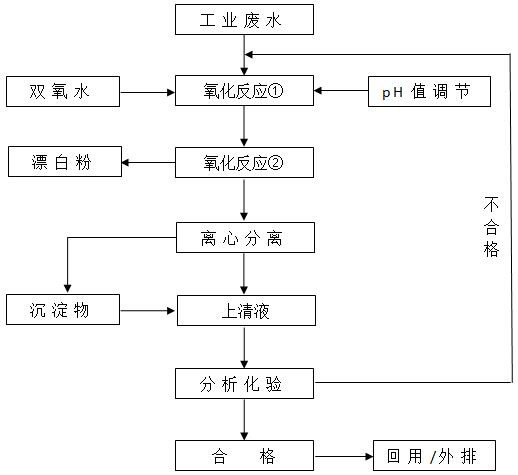

[0034] A method utilizing hydrogen peroxide-bleaching powder to jointly oxidize and degrade sulfides in industrial wastewater, the method comprising the following steps:

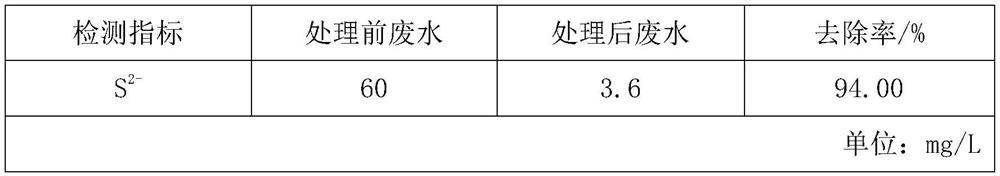

[0035] Step 1: Take 1L of industrial waste water (hereinafter referred to as waste water), add it into a reactor with heating function, adjust the pH value of the waste water to 9, and add dropwise hydrogen peroxide with a mass concentration of 28% in the reactor, and the hydrogen peroxide droplet acceleration rate Controlled at 0.1L / min, the molar ratio of hydrogen peroxide to sulfide in wastewater (based on available chlorine and S 2- Calculate) is 0.2:1, reaction 1h;

[0036] Step 2, adjusting the pH value of the wastewater treated in step 1 to be 2, then adding the bleaching powder with a mass content of available chlorine of 25%, the mol ratio of the bleaching powder and sulfide in the wastewater (in terms of available chlorine and S 2- ) was 2.2:1, the heating reaction temperature was controlled at 25°C...

Embodiment 2

[0041] A method utilizing hydrogen peroxide-bleaching powder to jointly oxidize and degrade sulfides in industrial wastewater, the method comprising the following steps:

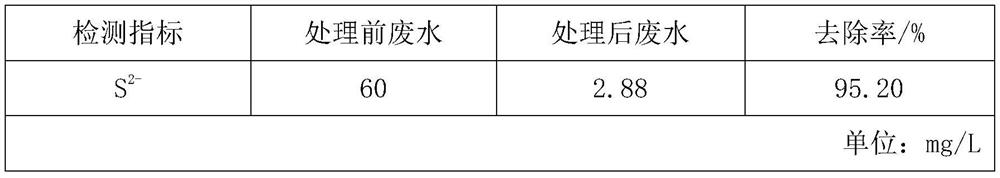

[0042] Step 1: Measure 1L of industrial waste water (hereinafter referred to as waste water), add it into a reactor with heating function, adjust the pH value of the waste water to 10, and add dropwise hydrogen peroxide with a mass concentration of 30% in the reactor, and the hydrogen peroxide droplet acceleration rate Controlled at 0.2L / min, the molar ratio of hydrogen peroxide to sulfide in wastewater (based on available chlorine and S 2- Calculate) is 0.4:1, reaction 2h;

[0043] Step 2, adjusting the pH value of the wastewater treated in step 1 to be 5, then adding the bleaching powder with a mass content of available chlorine of 35%, the mol ratio of the bleaching powder and sulfide in the waste water (in terms of available chlorine and S 2- ) was 2.0:1, the heating reaction temperature was controlled ...

Embodiment 3

[0048] A method utilizing hydrogen peroxide-bleaching powder to jointly oxidize and degrade sulfides in industrial wastewater, the method comprising the following steps:

[0049] Step 1: Measure 1L of industrial waste water (hereinafter referred to as waste water), add it into a reactor with heating function, adjust the pH value of the waste water to 11, add dropwise hydrogen peroxide with a mass concentration of 30% in the reactor, and the hydrogen peroxide droplet acceleration rate Controlled at 0.15L / min, the molar ratio of hydrogen peroxide to sulfide in wastewater (based on available chlorine and S 2- Calculate) is 0.6:1, reaction 3h;

[0050] Step 2, adjusting the pH value of the wastewater treated in step 1 to be 7, then adding the bleaching powder with a mass content of available chlorine of 30%, the mol ratio of the bleaching powder and sulfide in the wastewater (in terms of available chlorine and S 2- ) was 1.8:1, the heating reaction temperature was controlled at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com