Preparation method of precipitation-resistant halogen-free flame retardant special for polypropylene

A technology of precipitation resistance and flame retardant, which is applied in the field of flame retardancy, can solve the problems of failure to reach RTI level, lower flame retardancy of polymers, and poor mechanical properties of PP, etc., to achieve reduced octabromoether precipitation rate, strong mechanical properties, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

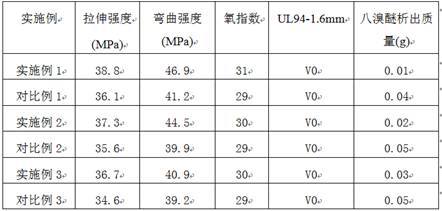

Examples

Embodiment 1

[0026] Example 1 A preparation method of a special precipitation-resistant halogen-free flame retardant for polypropylene

[0027] A special precipitation-resistant halogen-free flame retardant for polypropylene, comprising the following raw materials in parts by weight: 90 parts of layered silicate intercalation modified octabromoether, 5 parts of flame retardant synergist, and 5 parts of surface modifier part; the flame retardant synergist is aluminum diethyl hypophosphite; the surface modifier is silane KH550;

[0028] The layered silicate intercalation modified octabromoether, in parts by weight, includes the following raw materials: 100 parts of octabromoether, 15 parts of layered silicate, 5 parts of surfactant, 1 part of intercalation modifier share;

[0029] The octabromoether is bis(2,3-dibromopropyl) ether of tetrabromobisphenol A.

[0030] Described phyllosilicate is montmorillonite;

[0031] Described tensio-active agent is sodium octadecyl sulfate;

[0032] Th...

Embodiment 2

[0040] Example 2 A preparation method of a special precipitation-resistant halogen-free flame retardant for polypropylene

[0041] A special precipitation-resistant halogen-free flame retardant for polypropylene, comprising the following raw materials in parts by weight: 70 parts of layered silicate intercalation modified octabromoether, 20 parts of flame retardant synergist, 3 parts of surface modifier part; the flame retardant synergist is melamine pyrophosphate; the surface modifier is silane KH550;

[0042] The layered silicate intercalation modified octabromoether includes the following raw materials in parts by weight: 100 parts of octabromoether, 20 parts of layered silicate, 5 parts of surfactant, 1 part of intercalation modifier share;

[0043] The octabromoether is bis(2,3-dibromopropyl) ether of tetrabromobisphenol A.

[0044] The layered silicate is attapulgite powder;

[0045] Described tensio-active agent is sodium octadecyl sulfate;

[0046] The intercalatio...

Embodiment 3

[0054] Example 3 A preparation method of a special precipitation-resistant halogen-free flame retardant for polypropylene

[0055] A special precipitation-resistant halogen-free flame retardant for polypropylene, comprising the following raw materials in parts by weight: 80 parts of layered silicate intercalation modified octabromoether, 30 parts of flame retardant synergist, and 1 surface modifier part; the flame retardant synergist is silicon dioxide; the surface modifier is silane KH550;

[0056] The layered silicate intercalation modified octabromoether includes the following raw materials in parts by weight: 100 parts of octabromoether, 5 parts of layered silicate, 5 parts of surfactant, 1 part of intercalation modifier share;

[0057] The octabromoether is bis(2,3-dibromopropyl) ether of tetrabromobisphenol A.

[0058] The layered silicate is kaolin;

[0059] Described tensio-active agent is sodium octadecyl sulfate;

[0060] The intercalation modifier is cetyltrimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com