High-strength flame-retardant drainage pipe and preparation method thereof

A drainage pipe, high-strength technology, applied in the field of waste plastic recycling technology and pipe preparation, can solve the problems of limited use field, high processing cost, waste of resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

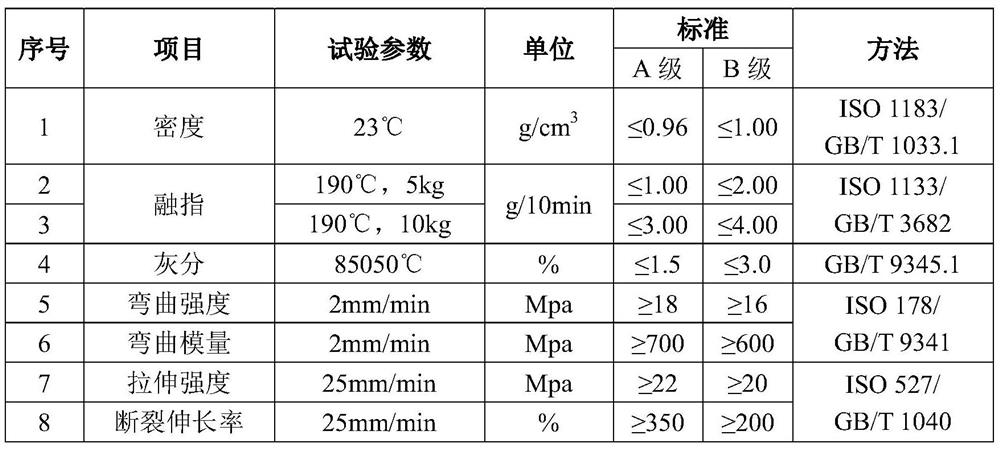

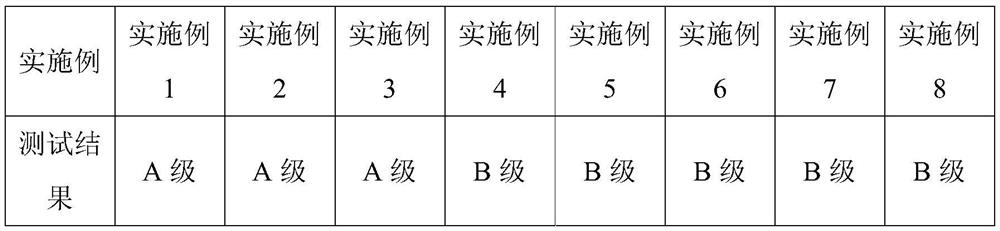

Examples

preparation example Construction

[0033] In the present invention, the preparation method of the regenerated polyethylene material comprises the following steps:

[0034] (1) Crushing: Crushing waste plastic barrels to obtain broken materials;

[0035] (2) Impurity removal: Soak the crushed material in hot alkaline water, then polish and clean it to remove surface impurities; after dehydration, remove light impurities by winnowing;

[0036] (3) Drying: drying the crushed material obtained in step (2) until the moisture content is not higher than 0.5wt%.

[0037] In a preferred embodiment, the crushed material has an average particle size of 10-80 mm.

[0038] In a preferred embodiment, the hot alkaline water is an aqueous solution of sodium hydroxide / potassium hydroxide at a temperature of 50-100°C.

[0039] In a more preferred embodiment, the concentration of the sodium hydroxide / potassium hydroxide is 0.1-10wt%.

[0040] In a preferred embodiment, the drying temperature is 60-100°C.

[0041] filler

...

Embodiment 1

[0080] Embodiment 1 provides a high-strength flame-retardant drainage pipe. The raw materials for the preparation of the drainage pipe include at least the following components in parts by weight: 75 parts of recycled polyethylene materials, 10 parts of fillers, 4 parts of metal powder, retardant 4 parts of fuel, 1.5 parts of other additives.

[0081] The preparation method of described recycled polyethylene material comprises the following steps:

[0082] (1) crushing: crushing waste plastic barrels to obtain crushed material, the average particle size of which is 12 ± 5mm;

[0083] (2) Impurity removal: Soak the crushed material in hot alkaline water, then polish and clean it to remove surface impurities; after dehydration, remove light impurities by winnowing;

[0084] (3) Drying: drying the crushed material obtained in step (2) at 100°C until the moisture content is not higher than 0.5wt%.

[0085] Described filler is modified glass fiber; The preparation method of descr...

Embodiment 2

[0095] Embodiment 2 provides a high-strength flame-retardant drainage pipe. The raw materials for the preparation of the drainage pipe include at least the following components in parts by weight: 60 parts of recycled polyethylene materials, 5 parts of fillers, 1 part of metal powder, retardant 1 part of fuel, 1 part of other additives.

[0096] The preparation method of described recycled polyethylene material comprises the following steps:

[0097] (1) crushing: crushing waste plastic barrels to obtain crushed material, the average particle size of which is 12 ± 5mm;

[0098] (2) Impurity removal: Soak the crushed material in hot alkaline water, then polish and clean it to remove surface impurities; after dehydration, remove light impurities by winnowing;

[0099] (3) Drying: drying the crushed material obtained in step (2) at 100°C until the moisture content is not higher than 0.5wt%.

[0100] Described filler is modified glass fiber; The preparation method of described m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com