Low-water-absorption toughened polyamide material and preparation method thereof

A technology of tough polyamide and low water absorption, which is applied in the field of toughened polyamide materials with low water absorption and its preparation, can solve the problems of limiting the use range of PA6 and PA66, affecting material performance, and adding more materials, etc. Dimensional stability, low cost, and the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

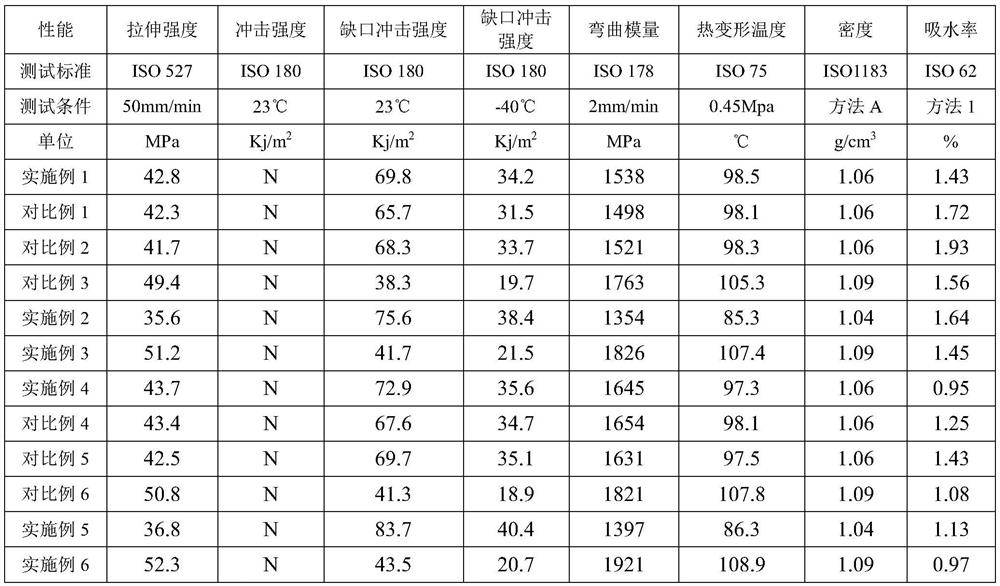

Examples

Embodiment 1

[0024] A toughened polyamide material with a low water absorption rate. In parts by weight, the toughened polyamide material with a low water absorption rate comprises the following components: 77 parts of PA6, 10 parts of EPDM-g-MAH, and 10% of methylol content 2 parts of octyl phenolic vulcanization resin, 10 parts of EPDM rubber, 1 part of brominated octyl phenolic vulcanization resin with 11% methylol content and 4.5% bromine content, 100.5 parts of antioxidant H, silicone 0.5 parts, silicone oil 0.03 parts.

Embodiment 2

[0026] A toughened polyamide material with a low water absorption rate. In parts by weight, the toughened polyamide material with a low water absorption rate comprises the following components: 70 parts of PA6, 8 parts of POE-g-MAH, and 10% of methylol content 1 part of octyl phenolic vulcanization resin, 20 parts of EPDM rubber, 1 part of brominated octyl phenolic vulcanization resin with 11% methylol content and 4.5% bromine content, 100.7 parts of antioxidant H, silicone 0.3 parts, 0.04 parts of silicone oil.

Embodiment 3

[0028] A toughened polyamide material with a low water absorption rate. In parts by weight, the toughened polyamide material with a low water absorption rate comprises the following components: 86 parts of PA6, 5 parts of PE-g-MAH, and 10% of methylol content 3 parts of octyl phenolic vulcanization resin, 5.5 parts of EPDM rubber, 0.5 parts of brominated octyl phenolic vulcanization resin with 11% methylol content and 4.5% bromine content, 0.8 parts of antioxidant H100, silicone 0.8 parts, silicone oil 0.05 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com