Method for lowering generation of succinic acid fermentation byproduct, i.e., acetic acid

A technology of succinic acid and by-products, which is applied in the field of reducing the production of acetic acid by-products of Dingersun fermentation, can solve the problem of high production of by-product acetic acid, and achieve the effects of improving raw material utilization, reducing costs, and reducing separation and purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

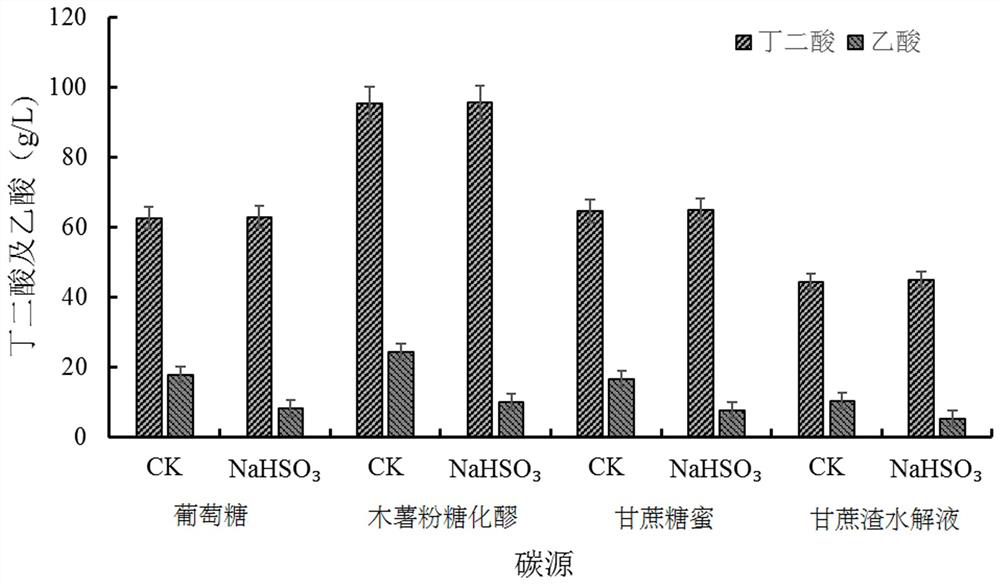

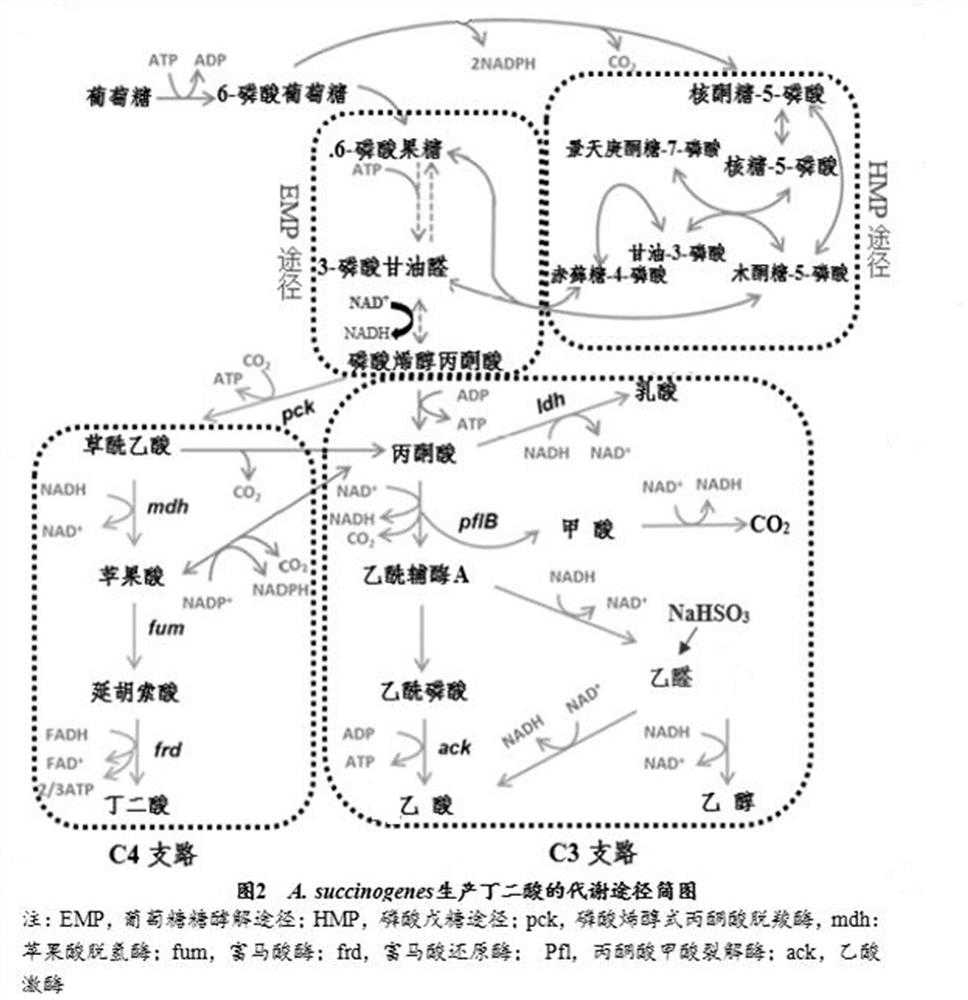

[0039] A method for reducing succinic acid fermentation by-product acetic acid generation, comprising the following steps:

[0040] (1) Inoculate a single colony of Actinobacillus succinogenes GXAS137 on the plate into the seed medium, and culture it in an anaerobic incubator at 37°C for 16 hours, and the number of bacteria reaches more than 300 million, and the expanded culture strain is obtained;

[0041](2) According to the inoculum amount of 5% (V / V), carry out secondary expansion and cultivation of the expanded culture for 8 hours until the number of bacteria reaches more than 300 million, that is, liquid seeds are obtained;

[0042] (3) According to the inoculum amount of 5% (V / V), inoculate the liquid seeds into a 250mL anaerobic bottle containing the fermentation medium, the liquid volume is 150mL, and add 0.05g / L sodium bisulfite at the same time, Use pH buffer to adjust the pH of the fermentation broth to maintain at 6.5-7.0, and then fill it with N 2 Under the cond...

Embodiment 2

[0050] A method for reducing succinic acid fermentation by-product acetic acid generation, comprising the following steps:

[0051] (1) Inoculate a single colony of Actinobacillus succinogenes GXAS137 on the plate into the seed medium, and culture it in a common incubator at 38°C for 20 hours, and the number of bacteria reaches more than 300 million, and the expanded culture strain is obtained;

[0052] (2) According to the inoculum amount of 5% (V / V), carry out the secondary expansion and cultivation of the expanded culture strains for 8 hours, and the number of bacteria reaches more than 300 million, that is, liquid seeds are obtained;

[0053] (3) Inoculate liquid seeds into a 250mL anaerobic bottle containing fermentation medium at an inoculum volume of 15% (V / V). , use the pH buffer to adjust the pH of the fermentation broth to maintain at 6.5-7.0, when it is filled with CO 2 Under the conditions of rotation speed 200r / min and temperature 38°C, batch fermentation was car...

Embodiment 3

[0060] A method for reducing succinic acid fermentation by-product acetic acid generation, comprising the following steps:

[0061] (1) Inoculate a single colony of Actinobacillus succinogenes GXAS137 on the plate into the seed medium, and culture it in an anaerobic incubator at 37°C for 16 hours, and the number of bacteria reaches more than 300 million, and the expanded culture strain is obtained;

[0062] (2) According to the inoculum amount of 5% (V / V), carry out the secondary expansion and cultivation of the expanded culture strains for 8 hours, and the number of bacteria reaches more than 300 million, that is, liquid seeds are obtained;

[0063] (3) According to the inoculum amount of 5% (V / V), inoculate the liquid seeds into the fermentation medium and ferment in a 2L fermenter with a liquid volume of 1200mL. Add 0.3g / L sodium bisulfite 6h after inoculation , use the pH buffer to adjust the pH of the fermentation broth to maintain at 6.5-7.0, and when it is full of N 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com