A New Quenching-Partitioning-Austempering Heat Treatment Method for Obtaining Si System Ultra-High Strength Disc Springs

An isothermal quenching and ultra-high-strength technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reduced brittle fracture strength and unusable products, and achieve the effect of rapid production and reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

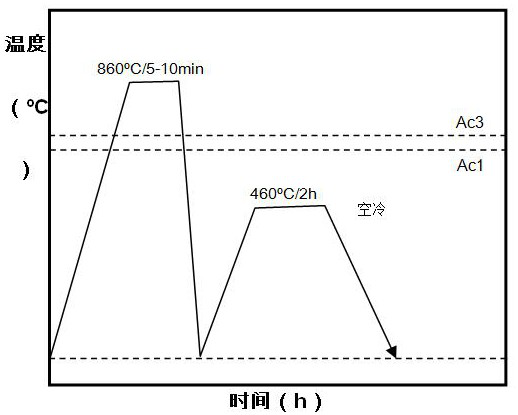

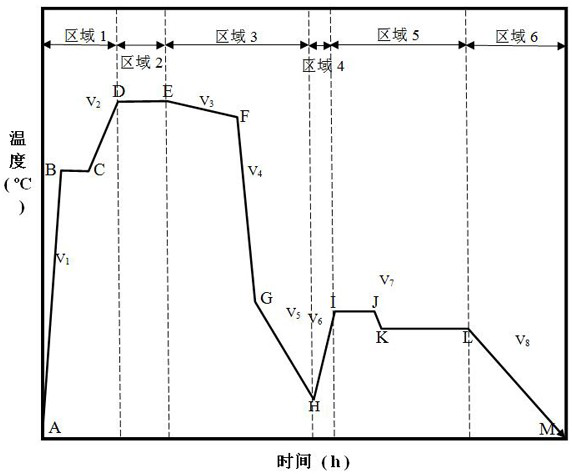

Method used

Image

Examples

Embodiment 1

[0056] Example 1: 60Si2Mn disc spring (outer diameter: 40mm, inner diameter: 20mm, effective thickness: 3mm)

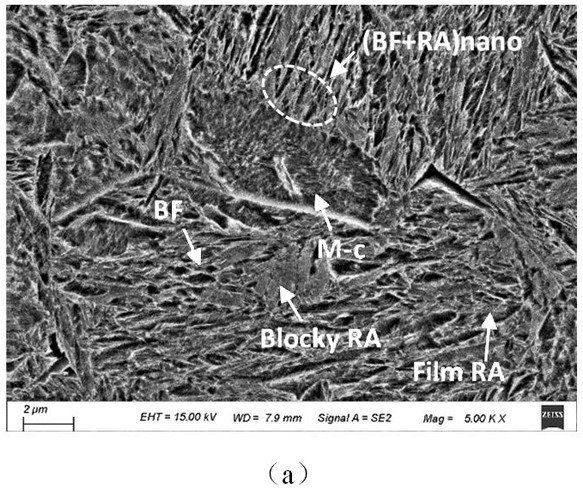

[0057] The microstructure of 60Si2Mn disc spring after treatment by Q-P-A (quenching-partitioning-austempering) process is shown in Figure 3. It can be seen that a multi-phase microstructure has been formed, and a nanoscale (less than 100nm) super bainite microstructure ((BF+RA)nano) is formed on the outside of the sheet-like carbon reduction M-c. It is beneficial to the improvement of the strength and toughness of the disc spring. In other areas, fine needle-like BF and membranous RA were obtained, and massive RA was also seen.

Embodiment 2

[0058] Embodiment 2: the comparison of different heat treatment processes 60Si2Mn disc spring tensile strength and hardness;

[0059] The comparison of the tensile strength and hardness of the 60Si2Mn disc spring after the Q-P-A (quenching-partitioning-austempering) heat treatment process described in the examples and the traditional heat treatment process is as follows: Figure 4 shown. It can be seen that compared with the disc spring of traditional technology, after the Q-P-A heat treatment process described in the embodiment, the hardness value has been greatly improved, from the original 40HRC to more than 56HRC, which is more than 1.4 times the original value. The strength increased from 1530MPa to 2520Mpa, which is 1.65 times of the original.

Embodiment 3

[0060] Embodiment 3: the comparison of different heat treatment processes 60Si2Mn disc spring compression performance;

[0061] The compression behavior of the 60Si2Mn disc spring after the Q-P-A (quenching-partitioning-austempering) heat treatment process described in the examples and the traditional heat treatment process is as follows Figure 5 shown. It can be seen that both disc springs did not fail. Compared with the traditional disc spring, after the Q-P-A heat treatment process described in the embodiment, the 60Si2Mn disc spring can withstand greater pressure under the same deflection of 1.3mm, which is 1.1 times that of the traditional disc spring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com