Carbonaceous material high-temperature wave-absorbing composite material and preparation method thereof

A technology of composite materials and carbonaceous materials, applied in the field of wave absorbing materials, can solve the problems of narrow absorption frequency band, low strength, and difficult engineering application implementation of composite materials, and achieve the improvement of magnetic permeability, convenient operation and high absorption strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

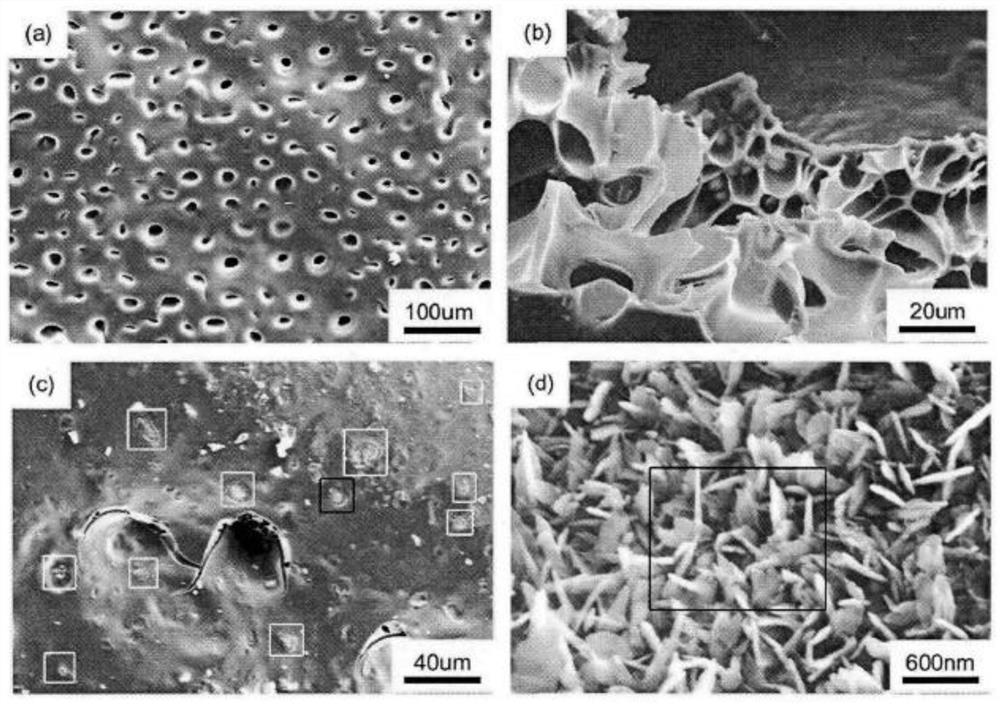

Image

Examples

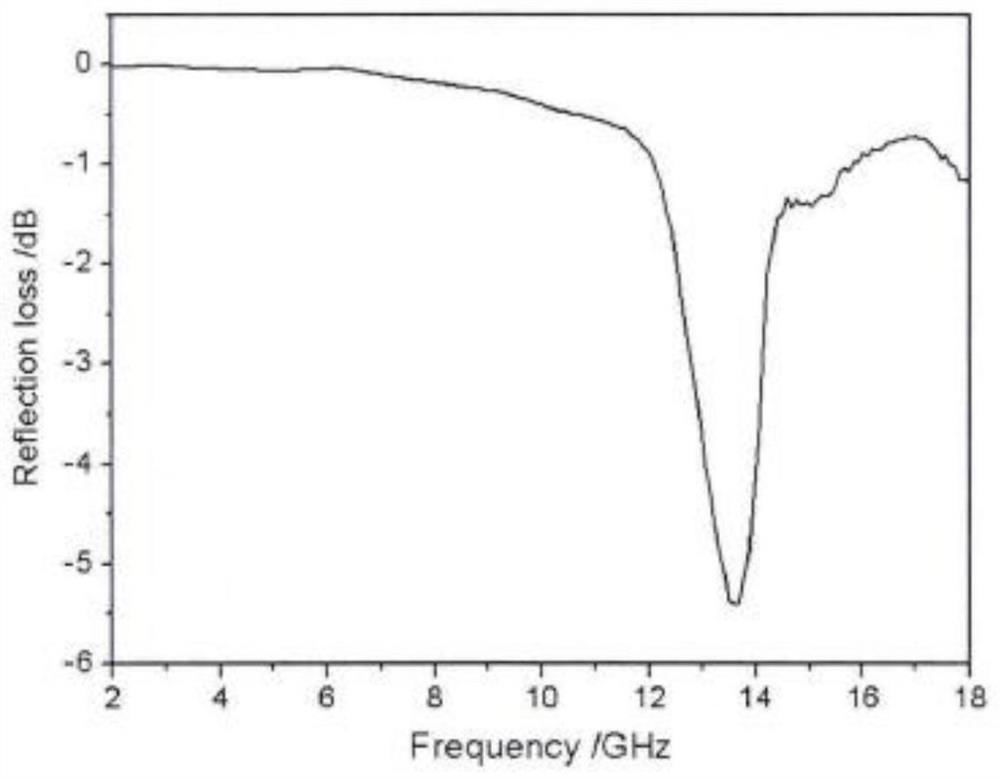

Embodiment 1

[0032] A method for preparing a carbonaceous material high-temperature wave-absorbing composite material, comprising the following steps:

[0033] (1) Add 20g of PVP to 800ml of 0.01mol / L ferrous sulfate aqueous solution, stir and dissolve, then quickly pour 400ml of prepared 0.03mol / L sodium borohydride aqueous solution, and continue to stir until the solution turns black, and the iron oxide is separated body, and washed for later use;

[0034] (2) Use 120ml of acrylonitrile as the first monomer, 6.5g of itaconic acid as the comonomer, then add 0.72g of azobisisobutyronitrile and 250ml of methyl sulfoxide, and polymerize at a constant temperature of 62°C for 24 hours. Obtain a polymerization mixture;

[0035] (3) Add the ferrite obtained in step (1) to the polymerization mixture obtained in step (2), stir and react in a constant temperature water bath at 62°C, and add silane coupling agent and 100-mesh graphene to the reaction system Micropowder 10g, after high-speed disper...

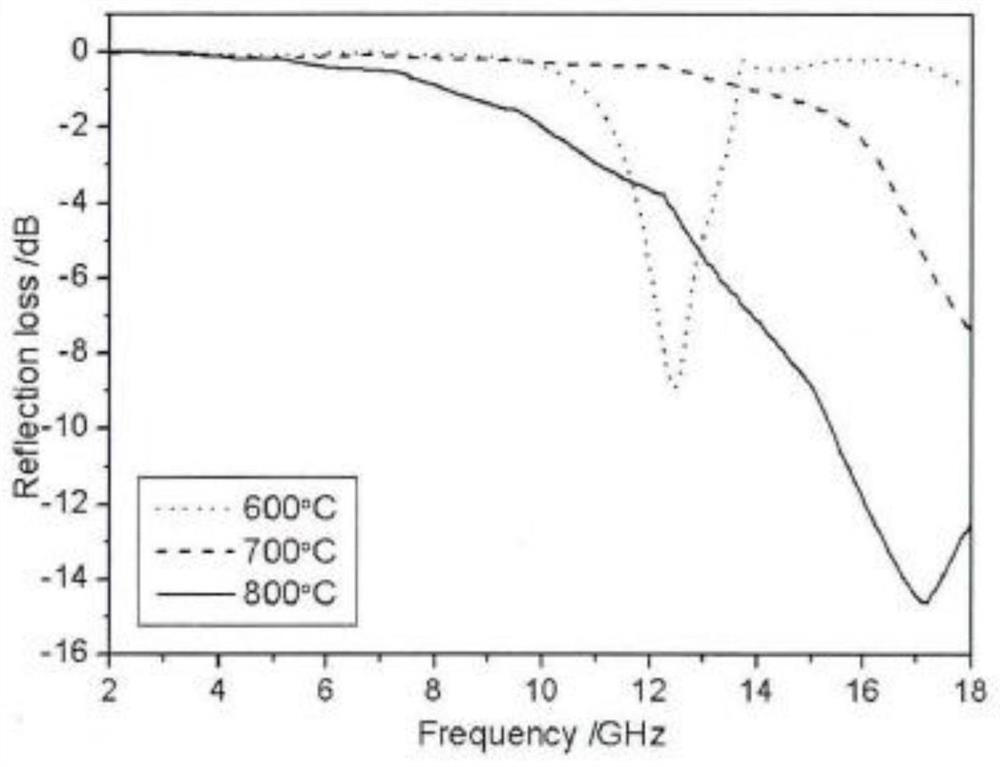

Embodiment 2

[0045] A method for preparing a carbonaceous material high-temperature wave-absorbing composite material, comprising the following steps:

[0046] (1) Add 16g of PVP to 800ml of 0.02mol / L ferrous sulfate aqueous solution, stir and dissolve, then quickly pour 400ml of prepared 0.03mol / L sodium borohydride aqueous solution, and continue stirring until the solution turns black, and the iron oxide is separated body, and washed for later use;

[0047] (2) Use 120ml of acrylonitrile as the first monomer, 6.5g of itaconic acid as the comonomer, then add 0.72g of azobisisobutyronitrile and 250ml of methyl sulfoxide, and polymerize at a constant temperature of 62°C for 24 hours. Obtain a polymerization mixture;

[0048] (3) Add the ferrite obtained in step (1) to the polymerization mixture obtained in step (2), stir and react in a constant temperature water bath at 62°C, and add silane coupling agent and 140 mesh graphene to the reaction system Micropowder 8g, obtain composite precur...

Embodiment 3

[0058] A method for preparing a carbonaceous material high-temperature wave-absorbing composite material, comprising the following steps:

[0059] (5) Add 13.3g of PVP to 800ml of 0.03mol / L ferrous sulfate aqueous solution, stir to dissolve, quickly pour 400ml of prepared 0.03mol / L sodium borohydride aqueous solution, and continue stirring until the solution turns black, and iron is separated Oxygen body, and wash it for later use;

[0060] (6) 120ml of acrylonitrile was used as the first monomer, 6.5g of itaconic acid was used as the comonomer, and then 0.72g of azobisisobutyronitrile and 250ml of methyl sulfoxide were added, and the polymerization reaction was carried out at a constant temperature of 62°C for 24 hours. Obtain a polymerization mixture;

[0061] (7) Add the ferrite obtained in step (1) to the polymerization mixture obtained in step (2), stir and react under the condition of constant temperature water bath at 62°C, and add silane coupling agent and 140 mesh gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com