Ultraviolet-irradiation-resistant colorless transparent polyimide film and preparation method and application thereof

A transparent polyimide, UV-resistant technology, applied in the field of functional polyimide, can solve the problems of CPI film anti-UV application, inability to adapt to application requirements, damage to film optical properties, etc., to achieve excellent anti-UV radiation Illumination characteristics, excellent UV radiation resistance, good UV stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

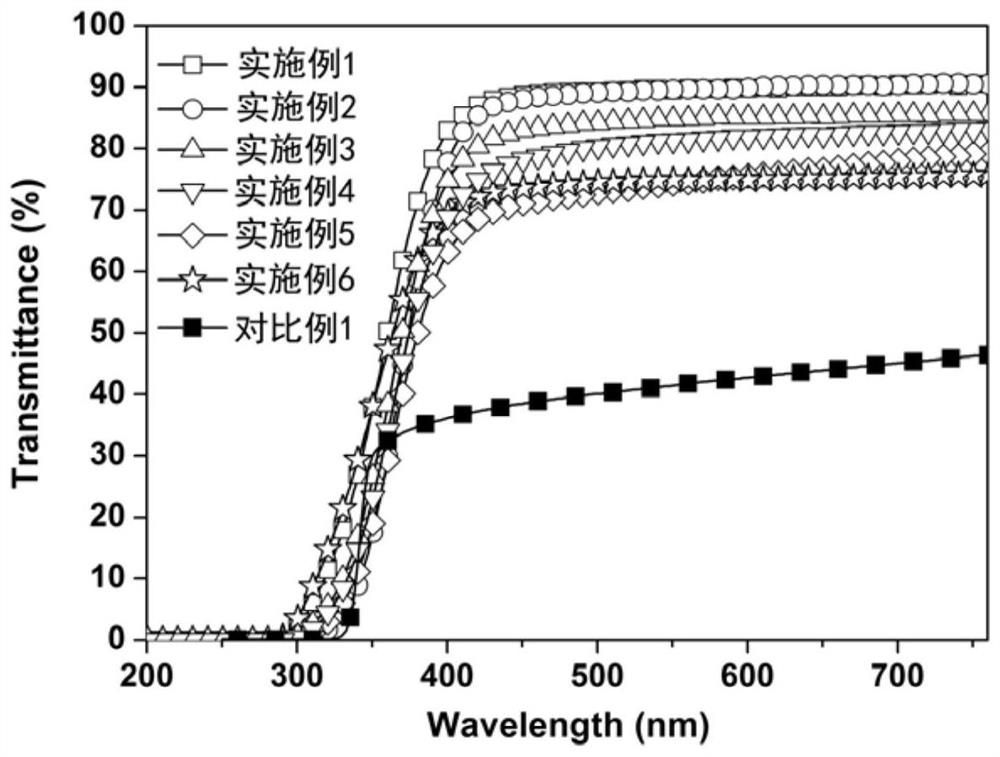

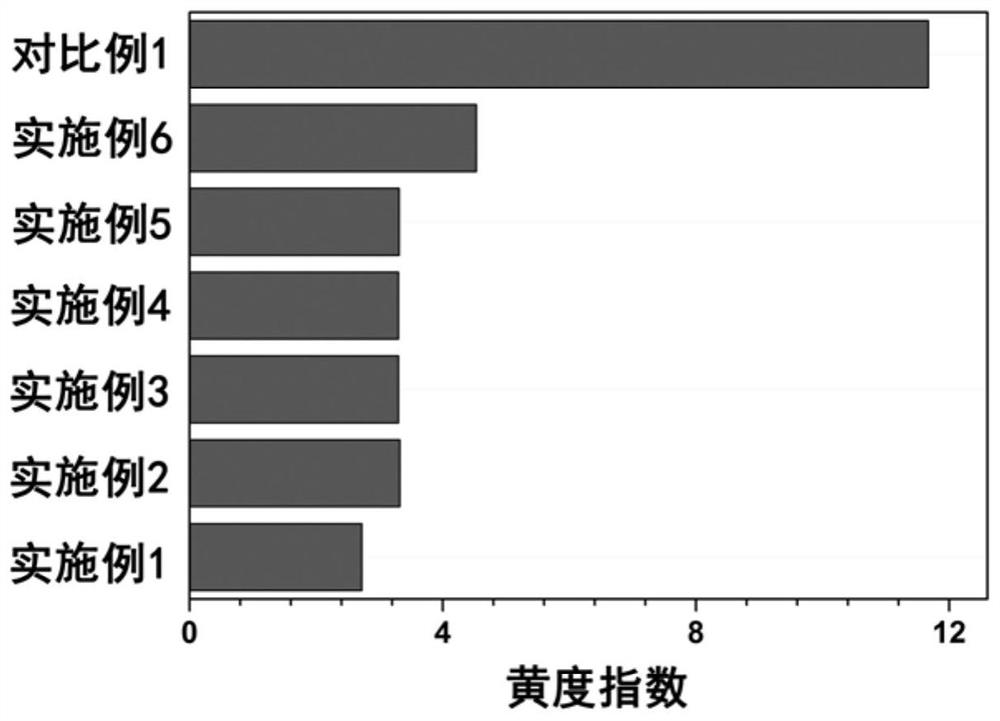

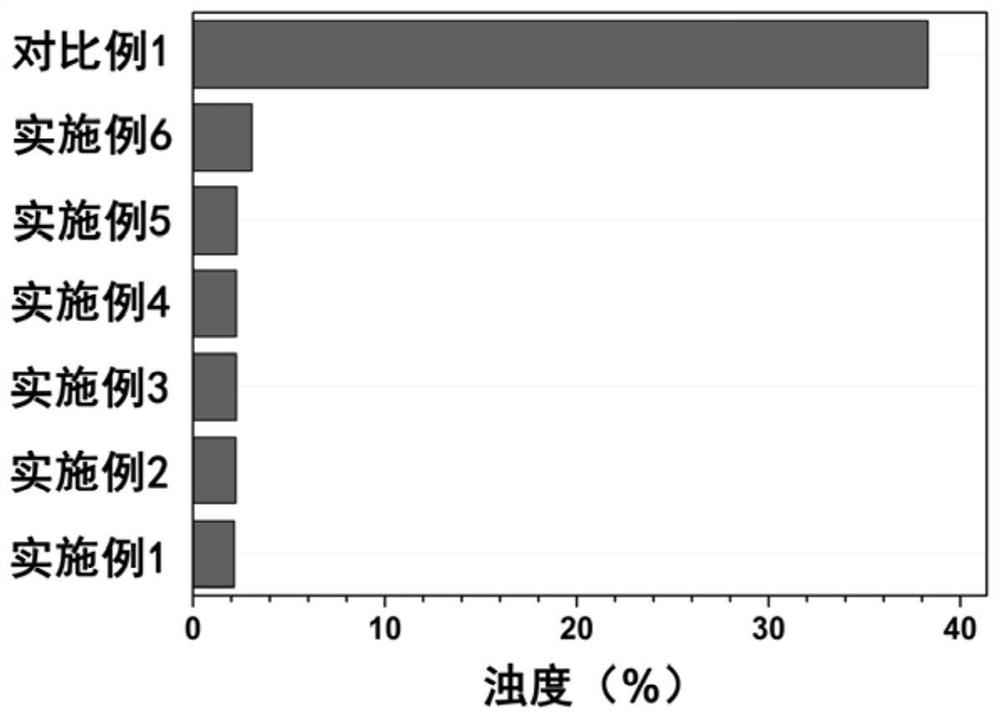

[0044] Embodiment 1 prepares PI (HPMDA-ODA) film (UV stabilizer content: 0) by HPMDA and ODA

[0045] Add 20.0240 g (0.1 mol) of ODA and 150 g of NMP into a 500 mL three-neck flask equipped with a heating mantle, mechanical stirring, thermometer, water separator, and reflux condenser. Nitrogen gas was introduced and a clear solution was obtained after mechanical stirring for 20 min. 22.4170 g (0.1 mol) HPMDA was added under stirring, and the viscosity of the system gradually increased. Add 20 g of NMP and stir at room temperature for 30 min to obtain a viscous solution. Add 0.5g pyridine and 150mL toluene as catalyst and azeotropic dehydrating agent respectively. When the system temperature rises to 130-140°C, the toluene / water azeotrope evaporates out of the water separator. Keep reflux for dehydration until no water drops come out of the system. Continue to heat up to 180°C and keep the temperature for 3h. Stop heating and cool to room temperature naturally. The obtain...

Embodiment 2

[0051] Embodiment 2 Cooperate UV stabilizer (formula II) by PI (HPMDA-ODA) and prepare UV-resistant type colorless transparent polyimide film (the quality of UV stabilizer accounts for 0.5% of the total mass of PI film, mass ratio)

[0052] The preparation process of PI resin is as in Example 1.

[0053] 7.5 g of the above resin was dissolved in 40 g of DMAc to obtain a PI solution (solution A). At the same time, 0.039475 g of the UV stabilizer represented by formula II was dissolved in 2.857 g of DMAc to obtain a UV stabilizer solution (solution B). Pour solution B into solution A to prepare a 15wt% PI composite solution. After the solution is mixed evenly, it is evenly coated on the surface of a clean glass plate by an automatic film coating machine, placed in a 100-class clean program temperature-controlled drying oven, and cured according to the following program: 50°C / 0.5h; 80°C / 3h; 120°C / 1h; 150°C / 1h; 180°C / 1h; 200°C / 1h; 250°C / 1h. Naturally cool to room temperature. ...

Embodiment 3

[0058] Embodiment 3 Cooperate UV stabilizer (formula III) by PI (HPMDA-ODA) and prepare UV-resistant type colorless transparent polyimide film (the quality of UV stabilizer accounts for 0.5% of the total mass of PI film, mass ratio)

[0059] The preparation process of PI resin is as in Example 1.

[0060] 7.5 g of the above resin was dissolved in 40 g of DMAc to obtain a PI solution (solution A). At the same time, 0.039475 g of the UV stabilizer represented by formula III was dissolved in 2.857 g of DMAc to obtain a UV stabilizer solution (solution B). Pour solution B into solution A to prepare a 15wt% PI composite solution. After the solution is mixed evenly, it is evenly coated on the surface of a clean glass plate by an automatic film coating machine, placed in a 100-class clean program temperature-controlled drying oven, and cured according to the following program: 50°C / 0.5h; 80°C / 3h; 120°C / 1h; 150°C / 1h; 180°C / 1h; 200°C / 1h; 250°C / 1h. Naturally cool to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com