Wave-absorbing material based on recycling of agricultural and forestry wastes and preparation method thereof

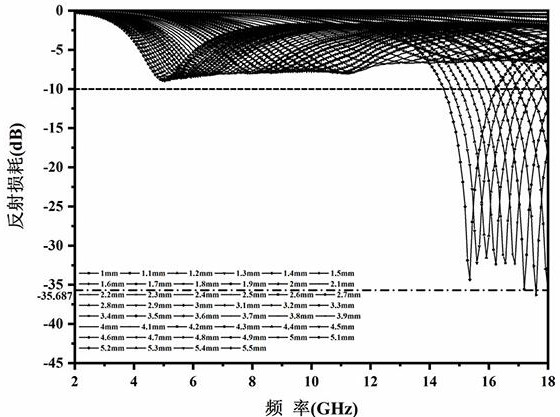

A technology of agricultural and forestry wastes and wave-absorbing materials is applied in the field of wave-absorbing materials based on the reuse of agricultural and forestry wastes and their preparation, and achieves the effects of rich types, good dielectric loss capability and improved microwave absorption capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

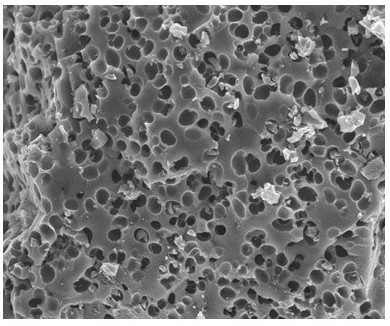

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is based on the microwave-absorbing material and its preparation method for the reuse of agricultural and forestry waste, including the following steps:

[0046] (1) Preparation of raw materials: Wash and crush the purchased walnut shells through a 60-mesh sieve, wash them with water and ethanol in sequence, and dry them for later use;

[0047] (2) Ultrasonic activation pretreatment: Take 5g of the dry shell powder from the previous step, mix it with the activator potassium hydroxide at a carbon agent mass ratio of 1:1.5, add it to 75ml deionized water, and perform ultrasonic pretreatment on it for 60 minutes. Filter and dry at 60°C;

[0048] (3) Stage heating carbonization treatment: Take an appropriate amount of the pretreated material in the previous step and put it into a tube furnace, and carry out carbonization reaction treatment in an argon atmosphere. The carbonization process adopts a staged temperature program. Stage heating and carbonization ...

Embodiment 2

[0051] This embodiment is based on the microwave-absorbing material and its preparation method for the reuse of agricultural and forestry waste, including the following steps:

[0052] (1) Preparation of raw materials: Wash and crush the purchased walnut shells through a 60-mesh sieve, wash them with water and ethanol in sequence, and dry them for later use;

[0053] (2) Ultrasonic activation pretreatment: Take 5g of the dry shell powder from the previous step, mix it with the activator potassium hydroxide at a carbon agent mass ratio of 1:1.5, add it to 75ml deionized water, and perform ultrasonic pretreatment on it for 60 minutes. Filter and dry at 60°C;

[0054] (3) Stage heating carbonization treatment: Take an appropriate amount of the pretreated material in the previous step and put it into a tube furnace, and carry out carbonization reaction treatment in an argon atmosphere. The carbonization process adopts a staged temperature program. Stage heating and carbonization ...

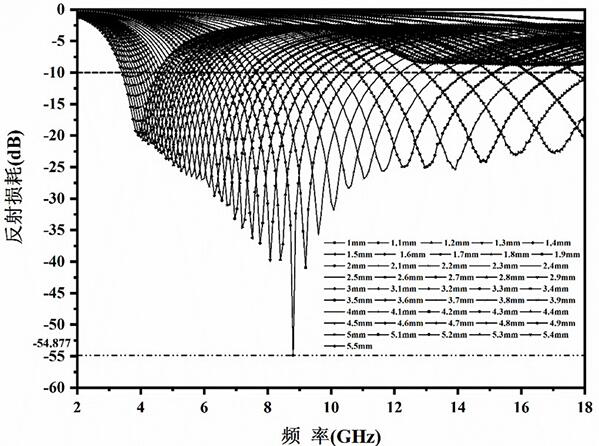

Embodiment 3

[0057] This embodiment is based on the microwave-absorbing material and its preparation method for the reuse of agricultural and forestry waste, including the following steps:

[0058] (1) Preparation of raw materials: Wash and pulverize the purchased radix sorbifolia husk through a 60-mesh sieve, wash with water and ethanol in sequence, and dry for later use;

[0059] (2) Ultrasonic activation pretreatment: Take 5g of the dried shell powder from the previous step, mix them with the activator potassium hydroxide and sodium hydroxide according to the carbon agent mass ratio of 1:1.5, add them to 75ml of deionized water, and perform ultrasonic pretreatment on it After 60 minutes, suction filter and dry at 60°C;

[0060] (3) Stage heating carbonization treatment: Take an appropriate amount of the pretreated material in the previous step and put it into a tube furnace, and carry out carbonization reaction treatment in an argon atmosphere. The carbonization process adopts a staged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com