Chemical treatment method of recycled aggregate for asphalt concrete

A technology for asphalt concrete and chemical treatment, applied in the field of recycled aggregate for asphalt concrete, can solve the problems of inability to adhere to the mortar reaction, cannot realize chemical modification of the surface of recycled aggregate, etc. The effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

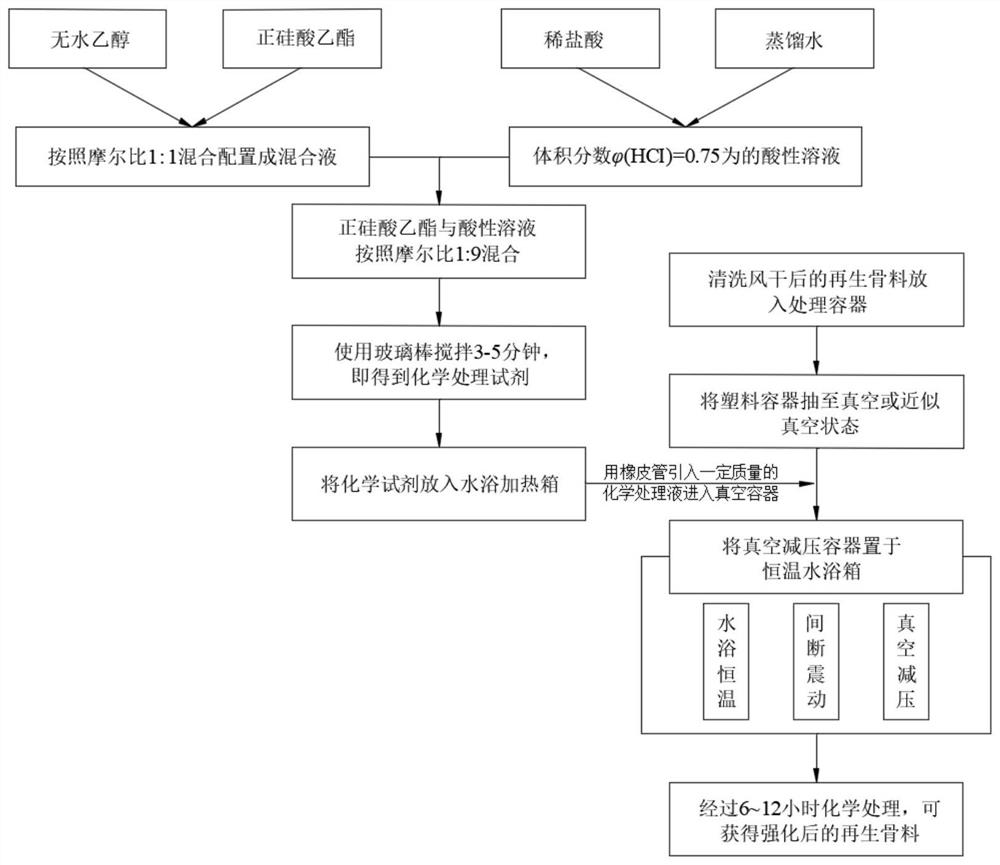

[0023] The preparation method of recycled aggregate chemical treatment reagent comprises the following steps, and the specific technological process is as follows: image 3 Shown:

[0024] 1) The molar ratio of tetraethyl orthosilicate to ethanol is 1:1. Calculate the mass of the two solutions according to the molar ratio, weigh them respectively, pour them into three beakers and stir for 1-2 minutes, and put them in a water bath for heating box for use;

[0025] 2) Dilute hydrochloric acid volume fraction Drop the calculated dilute hydrochloric acid into distilled water, control the pH of the obtained acidic solution at 2 to 3, and use a glass to stir evenly for 3 to 5 minutes;

[0026] 3) The molar ratio of tetraethyl orthosilicate to the acidic solution is 1:9, and the quality of the two solutions calculated according to the molar ratio is poured into the beaker respectively, and mixed evenly;

[0027] 4) Slowly pour the acidic solution into the prepared tetraethyl orth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap