Unsaturated carboxylic acid/styrene monomer/methoxy polyethylene glycol carboxylate copolymer and preparation method thereof and application thereof, and water suspending agent

A methoxy polyethylene glycol, styrene technology, applied in the field of water suspension agent, preparation, unsaturated carboxylic acid/styrene monomer/methoxy polyethylene glycol carboxylate copolymer, can Solve the problems of high stability, good fluidity, and low cost, and achieve the effects of low viscosity, cost reduction, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

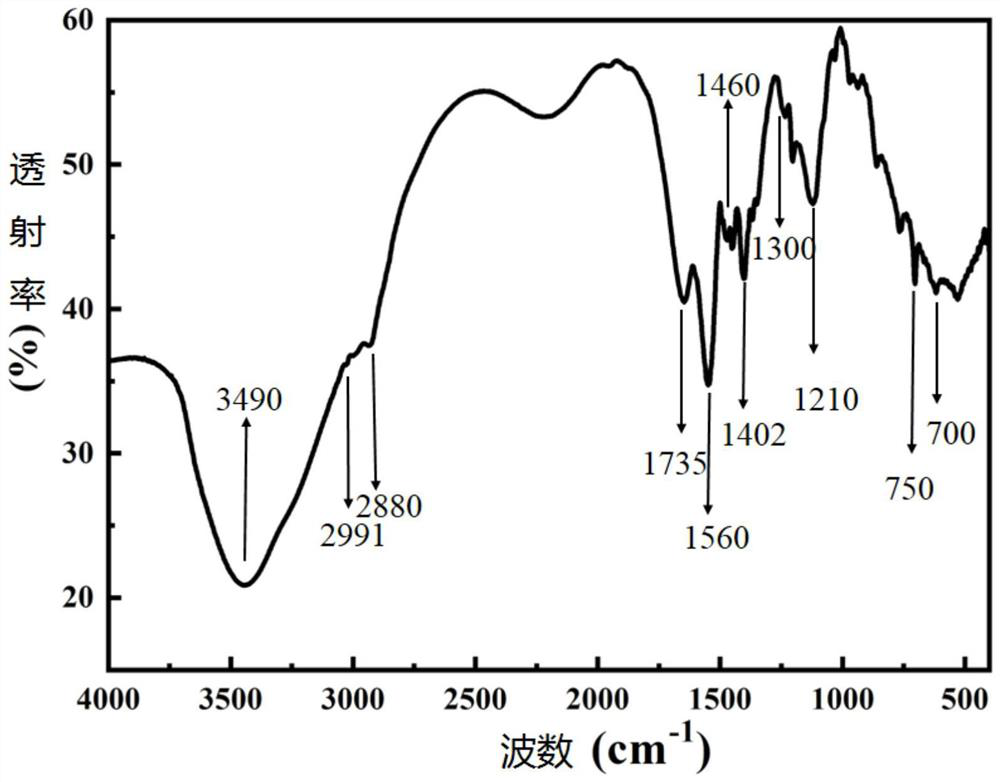

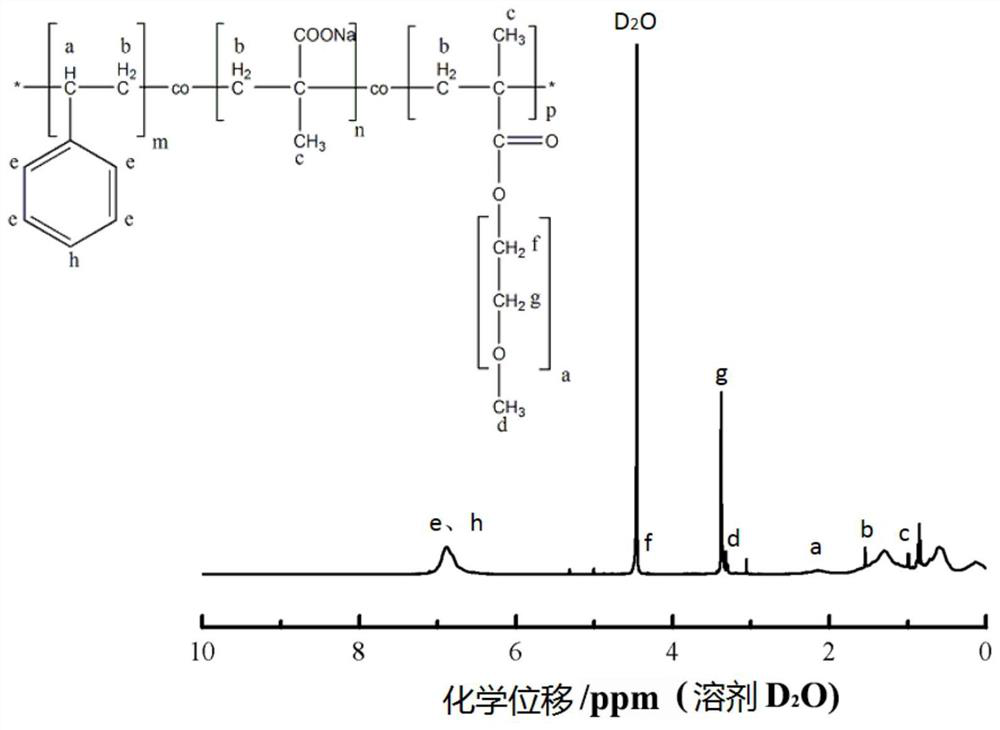

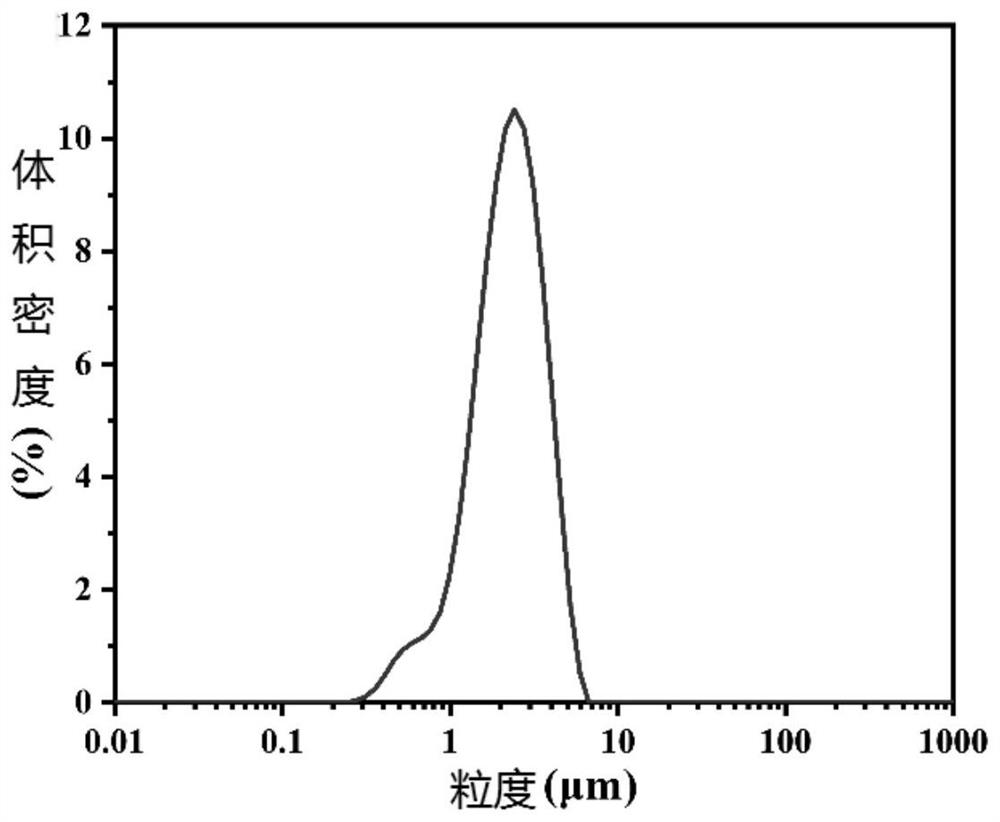

[0024] As described in the background art, the water suspension prepared by using the existing water dispersant cannot meet the performance requirements of low cost, high stability and good fluidity at the same time. In order to solve the above technical problems, the application provides a preparation method of unsaturated carboxylic acid / styrene monomer / methoxy polyethylene glycol unsaturated carboxylic acid ester copolymer, the preparation method comprising: making excessive unsaturated Carboxylic acid and methoxypolyethylene glycol carry out esterification reaction to obtain a mixed system containing unsaturated carboxylic acid and methoxypolyethylene glycol unsaturated carboxylic acid ester; base copolymerization reaction to obtain unsaturated carboxylic acid / styrene monomer / methoxypolyethylene glycol unsaturated carboxylate copolymer, wherein the weight average molecular weight of methoxypolyethylene glycol is 600~2000; The molar ratio of oxypolyethylene glycol, unsatura...

Embodiment 1

[0058] In the four-neck flask equipped with a thermometer, a stirring device, a spherical condenser, and a water separator, add 4.2g of methoxypolyethylene glycol (molecular weight 1000) and 1.8g of polymerization inhibitor hydroquinone, and then nitrogen gas , heat up to about 80°C, continue to heat up to 120°C under stirring, add 2.5g of p-toluenesulfonic acid, after the material is completely dissolved, add 90.4g of methacrylic acid dropwise to the reaction system for 1 hour, and then keep warm After reacting for 7 hours, the reaction system was cooled to room temperature to obtain a light brown mixed solution of methoxypolyethylene glycol methacrylate and methacrylic acid.

[0059]Add 170g of isopropanol and 60g of deionized water into a 500mL four-necked flask with a stirring and thermometer, stir and heat the system to 80°C, and at the same time add 43.7g of styrene and the above-mentioned synthesized methoxypolyethylene glycol methyl An initiator solution prepared from ...

Embodiment 2

[0061] In the four-necked flask equipped with thermometer, stirring device, spherical condenser and water separator, add 7.6g methoxypolyethylene glycol (molecular weight 1000) and 1.8g polymerization inhibitor hydroquinone, then nitrogen gas , heat up to about 80°C, continue to heat up to 120°C under stirring, add 2.5g of p-toluenesulfonic acid, after the material is completely dissolved, add 90.4g of methacrylic acid dropwise to the reaction system for 1 hour, and then keep warm After reacting for 7 hours, the reaction system was cooled to room temperature to obtain a light brown mixed solution of methoxypolyethylene glycol methacrylate and methacrylic acid.

[0062] Add 170g of isopropanol and 60g of deionized water into a 500mL four-necked flask with a stirring and thermometer, stir and heat the system to 80°C, and at the same time add 43.7g of styrene and the above-mentioned synthesized methoxypolyethylene glycol methyl An initiator solution prepared from a mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com