Antistatic super-strong printed cigarette film

An antistatic and super strong technology, applied in the field of packaging materials, can solve the problems of poor adhesion between the aluminized layer and the film, affecting the quality of the cigarette film, and poor adhesion of the ink, so as to achieve good product quality, good antistatic effect, and good surface The effect of resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the following examples: the preparation method of graphene supported by nano-silver, comprising the steps of: dispersing graphene oxide in water (graphene oxide whose sheet size is 30-50 μm), adding reducing agent A to form a reducing environment, and then Add silver ammonia solution, and then add reducing agent B to reduce silver ions to nano-silver, reduce graphene oxide and assemble it into graphene hydrogel, and obtain nano-silver-loaded graphene after drying; the preparation process is completed in an ultrasonic environment The silver ammonia solution is mixed in advance by ammonia water and silver nitrate; the preparation process is completed at normal temperature and pressure, the reducing agent A is ascorbic acid, and the reducing agent B is hydrazine hydrate; after adding the reducing agent B In the mixed solution, the concentration of graphene oxide is controlled at 1-3 mg / mL; in the mixed solution after adding reducing agent B, the mass ratio of silver nitr...

Embodiment 1

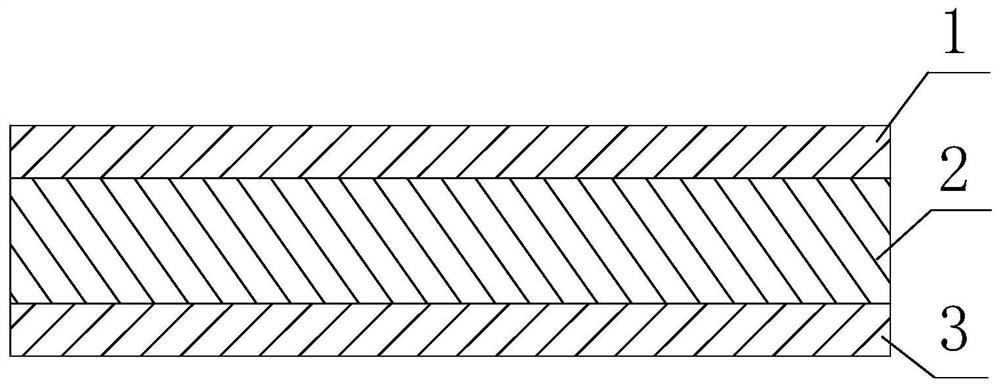

[0031] Such as figure 1 As shown, an antistatic super strong printed cigarette film (film used for cigarette packaging) is prepared by extruding a functional layer 1, a core layer (middle layer) 2, and a secondary functional layer 3. The core layer 2 is located at the functional Between layer 1 and secondary functional layer 3; the mass ratio of functional layer 1, core layer 2, and secondary functional layer 3 is 3:15:4;

[0032] The functional layer 1: the main function of this functional layer is heat sealing, imparting high-efficiency antistatic effect, and heating and heat sealing after packaging; the functional layer 1 is composed of ternary random copolymer polypropylene, antioxidant, graphene, nano-silver Prepared from loaded graphene and graphene-loaded silica composite materials, the mass percentages of each raw material are: ternary random copolymer polypropylene 96%, antioxidant 1%, graphene 2%, nano-silver loaded graphite 0.5% ene, 0.5% graphene-loaded silica com...

Embodiment 2

[0054] Such as figure 1 As shown, an antistatic super strong printed cigarette film (film used for cigarette packaging) is prepared by extruding a functional layer 1, a core layer (middle layer) 2, and a secondary functional layer 3. The core layer 2 is located at the functional Between layer 1 and secondary functional layer 3; the mass ratio of functional layer 1, core layer 2, and secondary functional layer 3 is 3:15:4;

[0055] The functional layer 1: the main function of this functional layer is heat sealing, imparting high-efficiency antistatic effect, and heating and heat sealing after packaging; the functional layer 1 is composed of ternary random copolymer polypropylene, antioxidant, graphene, nano-silver Prepared from supported graphene and graphene-supported silica composite materials, the mass percentage of each raw material is: ternary random copolymer polypropylene 98%, antioxidant 0.5%, graphene 0.5%, nano-silver loaded graphite 0.5% ene, 0.5% graphene-loaded si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com