Method for preparing ultra-coarse-grain tungsten carbide from medium-particle tungsten powder

A tungsten carbide and coarse-grained technology, applied in the direction of tungsten/molybdenum carbide, carbide, etc., can solve the problems of large equipment loss, large loss of carbonization equipment, ditungsten carbide, etc., and achieve high recovery rate and yield rate, reduction The effect of small equipment loss and small carbonization furnace loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing ultra-coarse-crystalline tungsten carbide with medium-grained tungsten powder, the specific steps are as follows:

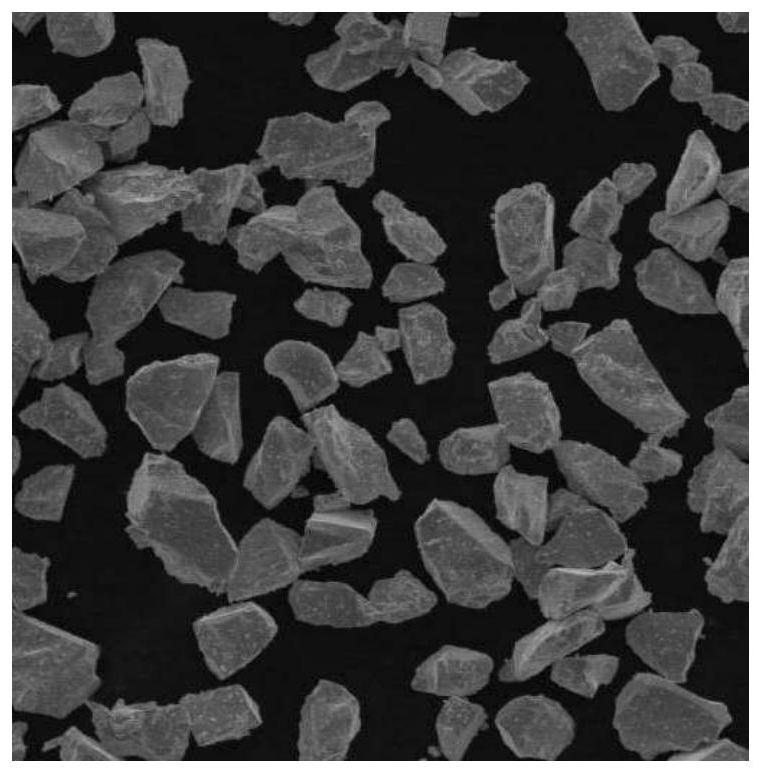

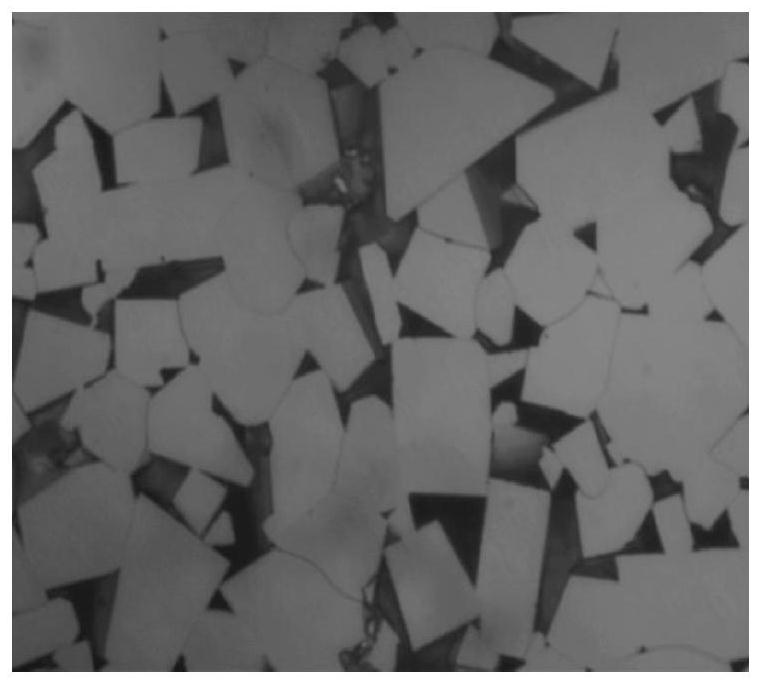

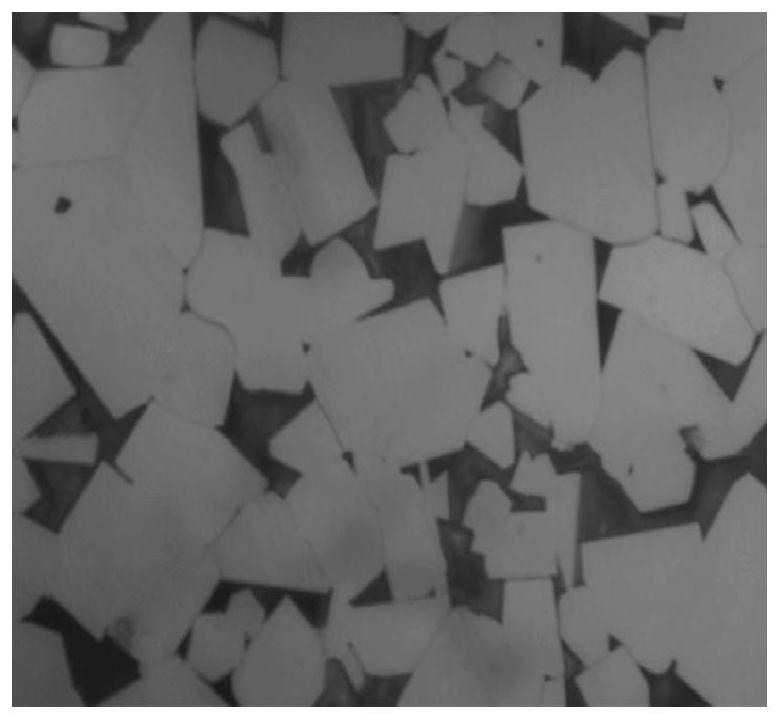

[0033] Mixing process: Weigh metal tungsten powder, carbon black, and metal cobalt powder for mixing. Among them, the metal tungsten powder is metal tungsten powder with a Fischer particle size of 2um, and the carbon black is carbon black that is required for a theoretical measurement of 5.13%. The weight of the cobalt powder is 2% of the weight of the metal tungsten powder, and after mixing, it is ball milled in a ball mill for 1 hour, so that the three kinds of powders are fully mixed evenly, and the primary mixed powder is obtained. Compression treatment: the primary mixed powder is molded, and the compression pressure is 1000kg / cm 2 , to obtain a compact. Carbonization treatment: place the green compact in an intermittent vacuum graphite resistance carbonization furnace for carbonization. First, evacuate the carbonization furnac...

Embodiment 2

[0036] A method for preparing ultra-coarse-crystalline tungsten carbide with medium-grained tungsten powder, the specific steps are as follows:

[0037] Mixing process: Weigh metal tungsten powder, carbon black, and metal cobalt powder to mix. Among them, the metal tungsten powder is metal tungsten powder with a Fischer particle size of 3um, and the carbon black is carbon black that is required for a theoretical measurement of 5.63%. The weight of the cobalt powder is 2% of the weight of the metal tungsten powder, and after mixing, it is ball-milled in a ball mill for 1.5 hours, so that the three kinds of powders are fully mixed evenly, and the primary mixed powder is obtained. Compression treatment: the primary mixed powder is molded, and the compression pressure is 1100kg / cm 2 , to obtain a compact. Carbonization treatment: place the compact in an intermittent vacuum graphite resistance carbonization furnace for carbonization. First, vacuum the carbonization furnace to 6Pa;...

Embodiment 3

[0040] A method for preparing ultra-coarse-crystalline tungsten carbide with medium-grained tungsten powder, the specific steps are as follows:

[0041]Mixing treatment: Weigh metal tungsten powder, carbon black, and metal cobalt powder to mix. Among them, the metal tungsten powder is metal tungsten powder with a Fischer particle size of 4um, and the carbon black is carbon black required for theoretical measurement of 6.13%. The weight of the cobalt powder is 3% of the weight of the metal tungsten powder, and after mixing, it is ball milled in a ball mill for 2 hours, so that the three kinds of powders are fully mixed evenly, and the primary mixed powder is obtained. Compression treatment: compression molding of the primary mixed powder, the compression pressure is 1200kg / cm 2 , to obtain a compact. Carbonization treatment: place the compact in an intermittent vacuum graphite resistance carbonization furnace for carbonization. First, vacuum the carbonization furnace to 8Pa; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com