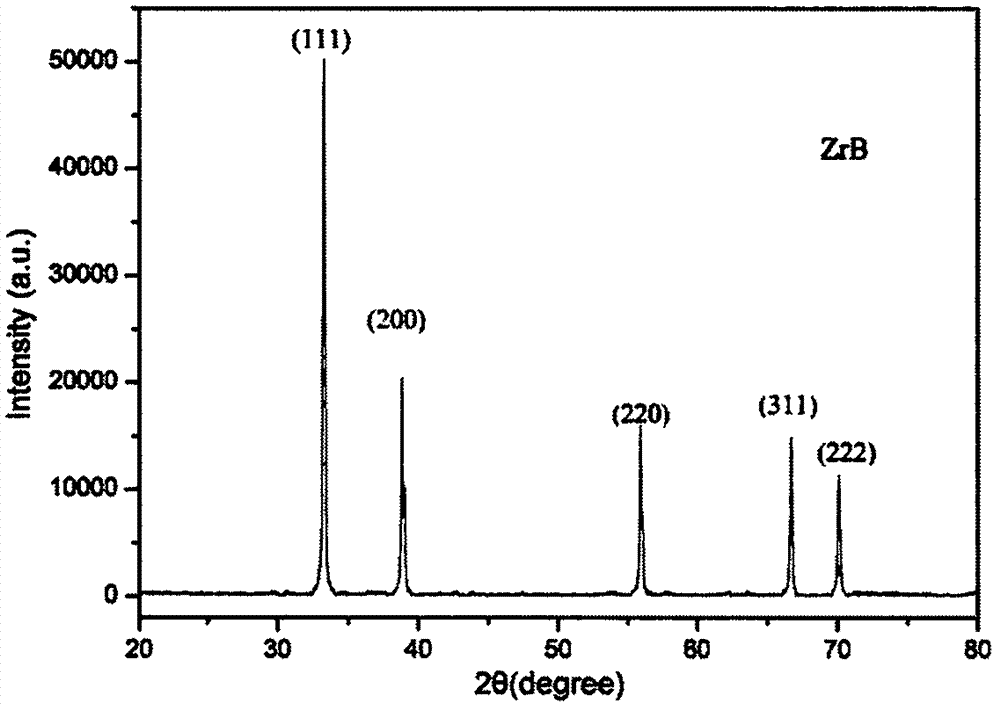

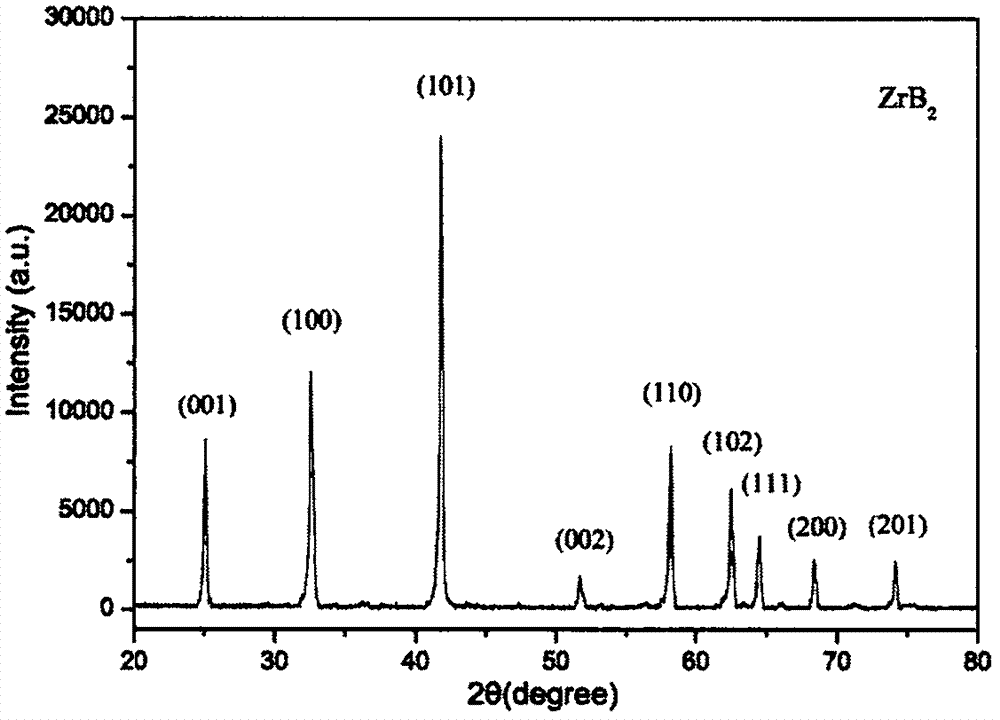

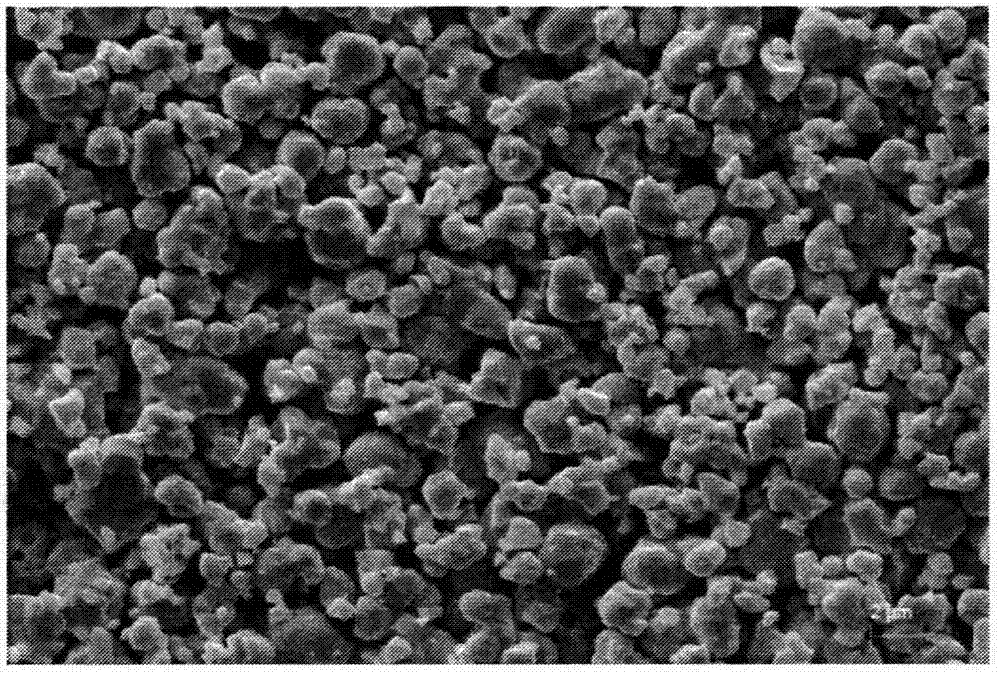

Preparation method of zirconium boride powder

A technology of zirconium boride and powder, which is applied in the field of preparation of zirconium boride powder, can solve the problems of increasing the difficulty of breaking into powder, not obtaining a single phase, and high cost of zirconium boride, so as to overcome the kinetic barrier, The effect of improving the purity and shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) First, place B powder and Zr powder in a graphite crucible coated with BN powder on the inner wall, and use a hydrogen reduction furnace to perform high-temperature reduction and removal of impurities. The reduction temperature of boron powder is 1000 ° C, and the reduction temperature of zirconium powder is 800 ° C. ℃;

[0044] (2) Add B powder and Zr powder after reduction and removal of impurities into the ball mill mixing tank for 4 hours according to the ratio of molar ratio of 1:1. The ball milling medium is edible alcohol. The material of tetrafluoroethylene;

[0045] (3) Pour the ball-milled mixture into a stainless steel tray, and then place it in a vacuum drying oven for drying. The drying temperature is 60° C., and the drying time is 48 hours;

[0046] (4) Transfer the dried material to a graphite crucible whose inner wall is coated with BN powder, and then place the graphite crucible in a high-temperature and high-pressure container. The heating rate w...

Embodiment 2

[0050] (1) First, place B powder and Zr powder in a graphite crucible coated with BN powder on the inner wall, and use a hydrogen reduction furnace to perform high-temperature reduction and removal of impurities. The reduction temperature of boron powder is 1500 ° C, and the reduction temperature of zirconium powder is 1100 ° C. ℃;

[0051] (2) Add B powder and Zr powder after reduction and removal of impurities into the ball mill mixing tank for 96 hours according to the molar ratio of 1:1. The ball milling medium is edible alcohol. The material of tetrafluoroethylene;

[0052] (3) Pour the ball-milled mixture into a stainless steel tray, and then place it in a vacuum oven for drying. The drying temperature is 100° C. and the drying time is 36 hours;

[0053] (4) Transfer the dried material to a graphite crucible whose inner wall is coated with BN powder, then place the graphite crucible in a high-temperature and high-pressure container, and control the pressure in the conta...

Embodiment 3

[0057] (1) First place B powder and Zr powder in graphite crucibles coated with BN powder on the inner wall, and use a hydrogen reduction furnace to perform high-temperature reduction and removal of impurities. The reduction temperature of boron powder is 1250 ° C, and the reduction temperature of zirconium powder is 950 ° C. ℃;

[0058] (2) Add B powder and Zr powder after reduction and removal of impurities into the ball mill mixing tank for 48 hours according to the molar ratio of 1:1. The ball milling medium is edible alcohol. The material of tetrafluoroethylene;

[0059] (3) Pour the ball-milled mixture into a stainless steel tray, and then place it in a vacuum drying oven for drying. The drying temperature is 80° C. and the drying time is 42 hours;

[0060] (4) Transfer the dried material to a graphite crucible whose inner wall is coated with BN powder, then place the graphite crucible in a high-temperature and high-pressure container, and control the internal pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com