Tripolyindenyl conjugated tri-BODIPY near-infrared fluorescent dye and preparation method thereof

A fluorescent dye, polyindenyl technology, applied in azo dyes, organic dyes, luminescent materials, etc., can solve the problems of many synthesis steps, poor solubility, limited application, etc., and achieves good solubility, simple and easy preparation method, The effect of good photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

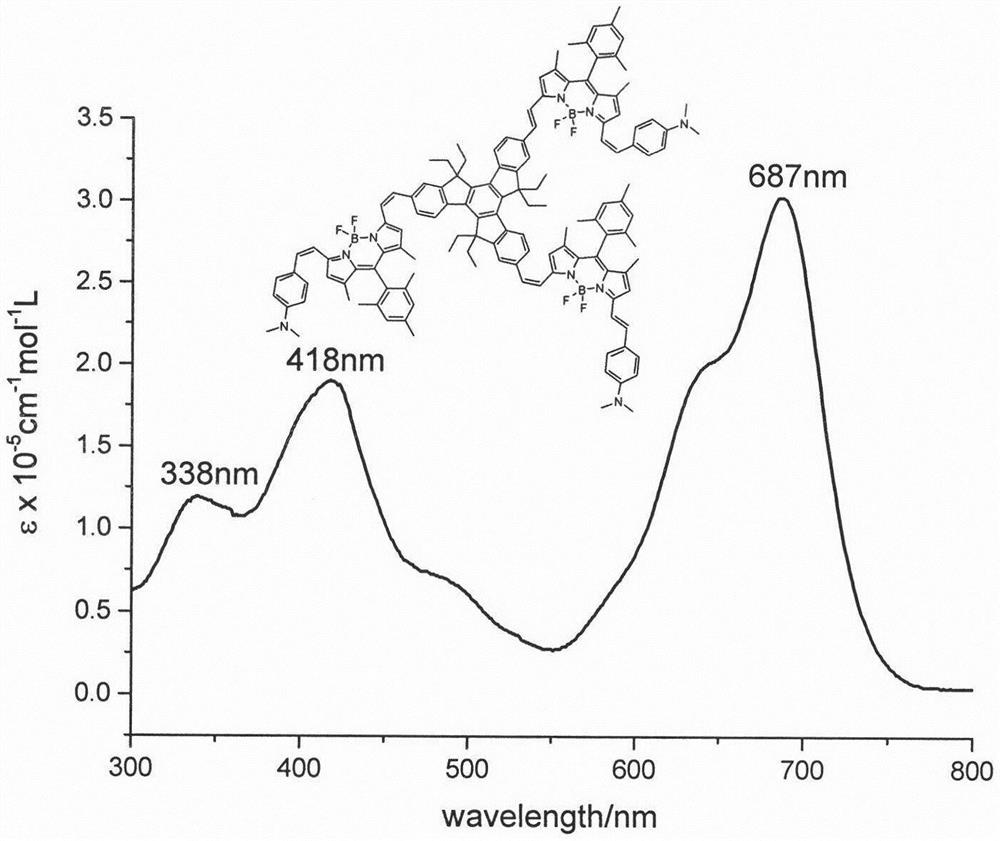

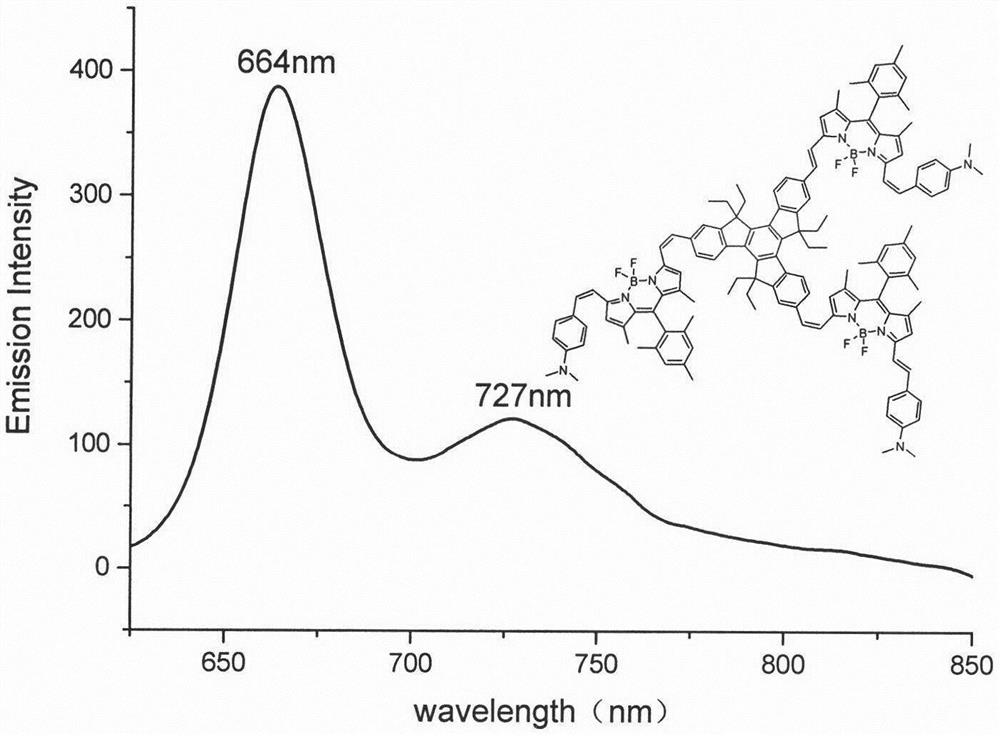

[0027] In a round bottom flask equipped with a Dean-Stark apparatus, 1,5,7-tetramethyl-3-(4-N-N-dimethyl)-vinylbenzene-8-(2,4,6-trimethylbenzene) -BODIPY (237mg, 0.477mmol), 2,7,12-triformyltripolyindene (94mg, 0.159mmol) and freshly dried p-toluenesulfonic acid (79mg) were dissolved in 25mL toluene and 1mL piperidine, and the mixture was heated to reflux for 24 hours, cooled to room temperature, diluted with dichloromethane, washed with water, the organic layer was dried over anhydrous sodium sulfate, the organic solvent was evaporated under reduced pressure, the residue was separated and purified by silica gel column chromatography, and the eluent was (100% CH 2 Cl 2 ) to obtain compound 1 (32 mg, 10%) as a black-green solid. 1 HNMR: (400MHz, CDCl 3 )δ8.46(d, 3H), 7.90(d, 3H), 7.79(d, 3H), 7.67(s, 4H), 7.64-7.53(m, 8H), 7.39(d, 3H), 7.28(d , 3H), 6.99(s, 6H), 6.69(t, 12H), 3.11(m, 6H), 3.04-2.90(m, 18H), 2.38(s, 9H), 2.32(dd, 6H), 2.17( s, 18H), 1.49 (d, 18H), 0.32 (t, 1...

Embodiment 2

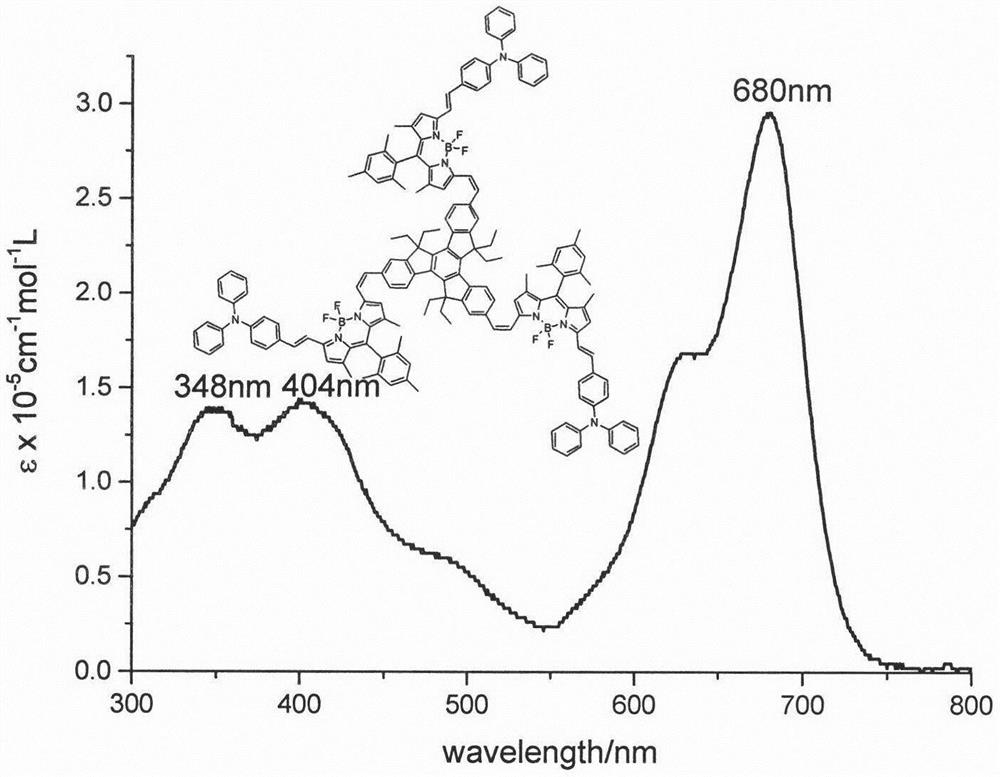

[0030] In a round bottom flask equipped with a Dean-Stark apparatus, 1,5,7-tetramethyl-3-(4-N,N-dianilinostyryl)-8-(2,4,6-trimethylbenzene )-BODIPY (415 mg, 0.63 mmol), 2,7,12-triformyltripolyindene (128 mg, 0.21 mmol) and freshly dried p-toluenesulfonic acid (100 mg) were dissolved in 25 mL of toluene and 1 mL of piperidine, and the mixture was heated to reflux 28 hours, cooled to room temperature, diluted with dichloromethane, washed with water, the organic layer was dried over anhydrous sodium sulfate, the organic solvent was evaporated under reduced pressure, the residue was separated and purified by silica gel column chromatography, and the eluent was (100% CH 2 Cl 2 ) to obtain black-green solid compound 2 (45 mg, 9%). 1 H NMR: (600MHz, CDCl 3 )δ8.43(d, J=8.4Hz, 3H), 7.86(d, J=16.2Hz, 3H), 7.80(d, J=7.8Hz, 3H), 7.72(d, J=16.2Hz, 3H) , 7.62(s, 3H), 7.56(d, J=8.4Hz, 1H), 7.54(d, J=8.4Hz, 6H), 7.43(d, J=16.2Hz, 3H), 7.39-7.37(m, 2H), 7.30(d, J=7.8Hz, 9H), 7.26(d, J=16.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com