A fluorescent polycarboxylate water reducer and its preparation method

A polycarboxylic acid-based and water-reducing agent technology is applied in the field of water-reducing agents for cement concrete, which can solve problems such as short service life, and achieve the effects of reducing reaction difficulty, rapid reaction and high efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

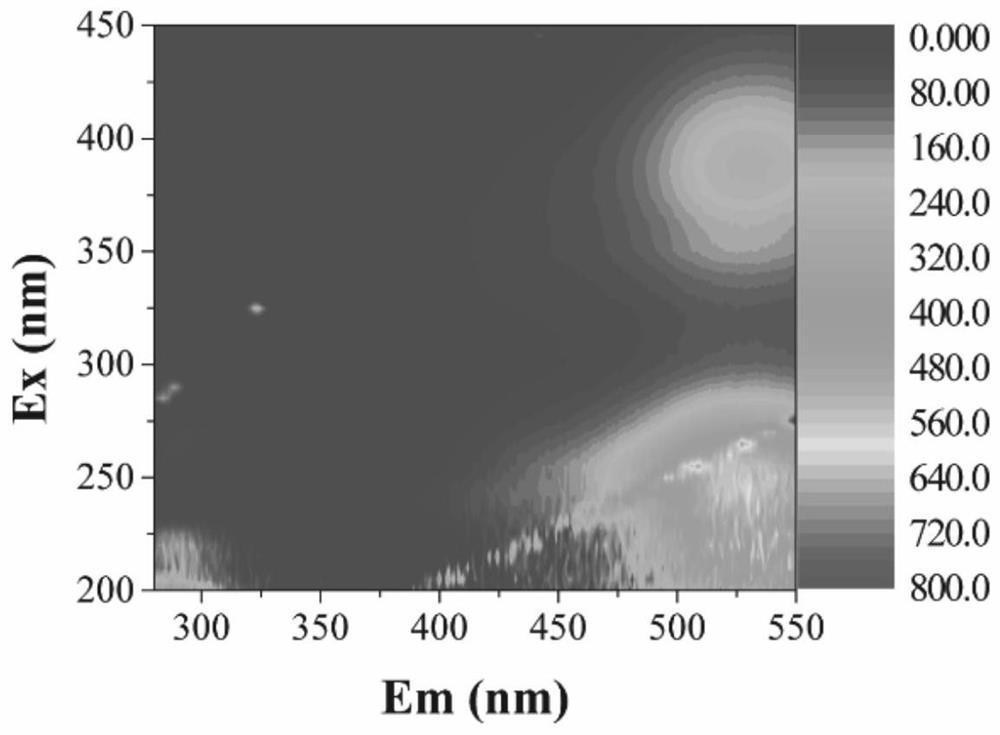

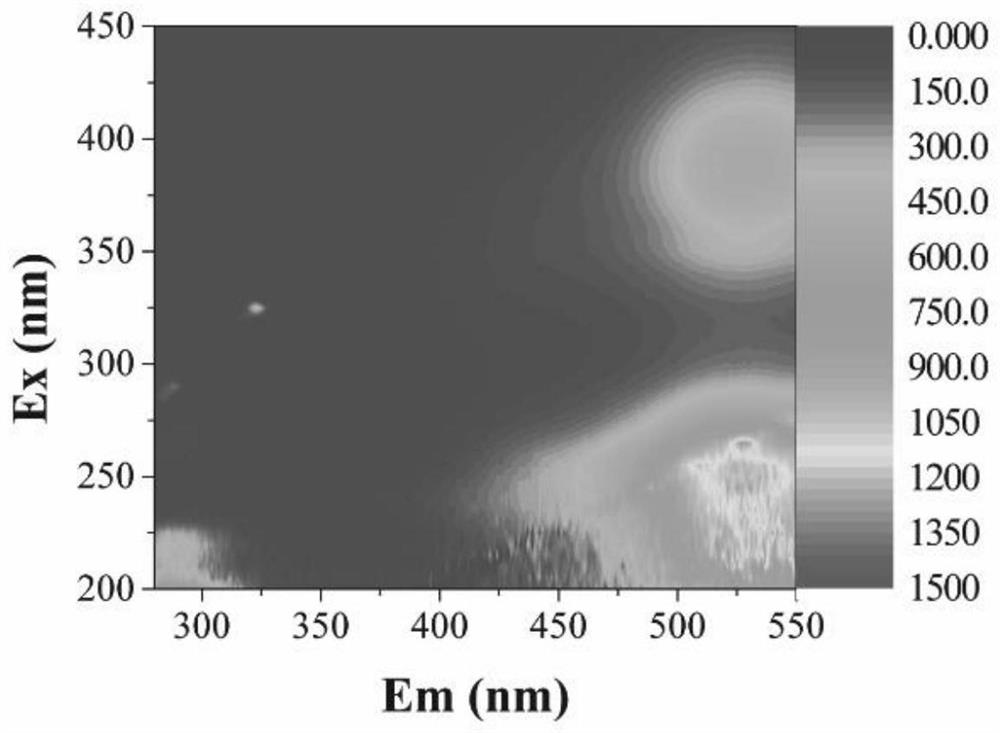

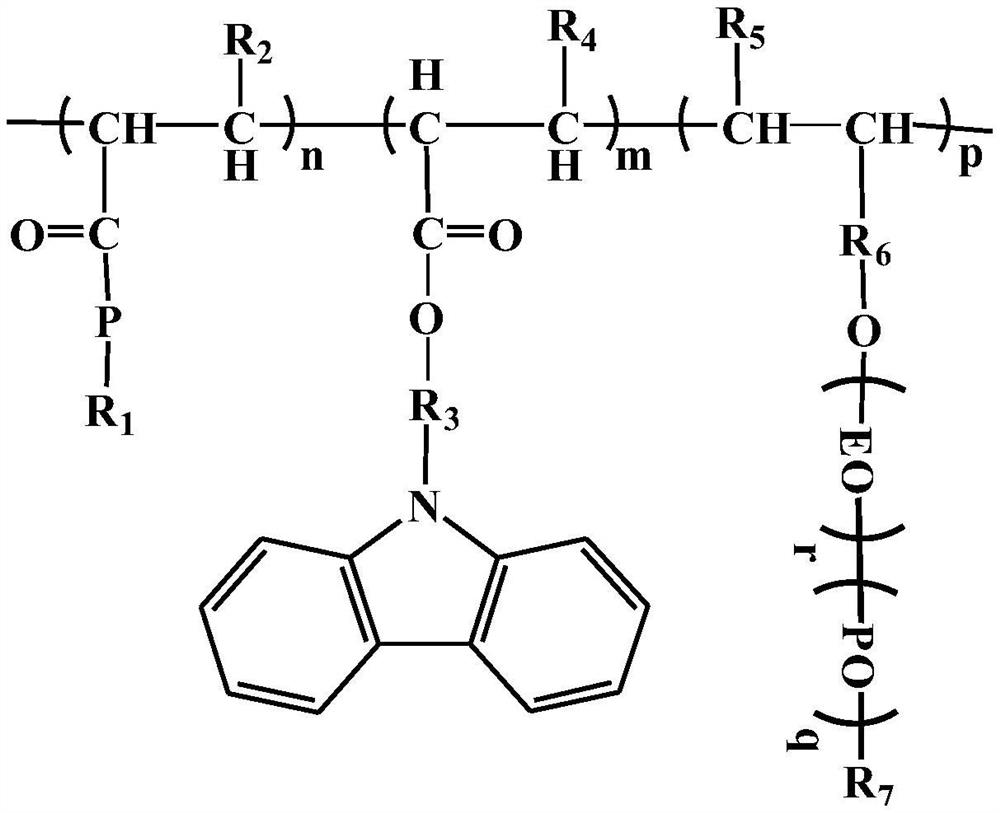

Image

Examples

Embodiment 1

[0027] 1) Keep 2 mol of acrylic acid, 1 mol of allyl polyethylene glycol (weight average molecular weight 300) under the combined action of 0.1 mol of hydrogen peroxide, 0.05 mol of white block, and 0.03 mol of 2-mercaptopropionic acid at a temperature of 5°C Carry out redox free radical polymerization reaction for 5 hours under low temperature to obtain the pre-product of water reducer;

[0028] 2) 1 mol of the water reducer pre-product obtained in step 1) and 10 mol of N-(hydroxyethyl) carbazole with fluorescent properties were subjected to an esterification reaction for 5 hours under the action of 0.1 mol of solid acid, and then potassium hydroxide was used to The pH value was adjusted to 7, and water was added to obtain a fluorescent polycarboxylate water reducer with a concentration of 60 wt % and a weight average molecular weight of 20,000.

Embodiment 2

[0030] 1) Keep 3mol methacrylic acid, 1mol methallyl polyethylene glycol (weight average molecular weight 800) under the action of 0.08mol ammonium persulfate, 0.1mol sodium sulfite and 0.04mol mercaptoethanol at a temperature of 15°C Carrying out 4 hours of redox radical polymerization to obtain the pre-product of water reducer;

[0031] 2) 1 mol of the pre-product of the water reducer obtained in step 1) and 7 mol of N-(hydroxymethyl) carbazole with fluorescent properties were subjected to an esterification reaction for 3 hours under the action of 0.08 mol of concentrated sulfuric acid, and then dissolved in sodium hydroxide The pH value was adjusted to 6, and water was added to obtain a fluorescent polycarboxylate water reducer with a concentration of 50 wt % and a weight average molecular weight of 40,000.

Embodiment 3

[0033] 1) 4mol sodium acrylate, 1mol 3-methyl-3-butene-1-polyethylene glycol (weight average molecular weight is 1000), in 0.06mol sodium persulfate, 0.15mol sodium metabisulfite and 0.05mol dodecanethiol Under the combined action, keep the temperature at 25°C for 3 hours for redox radical polymerization to obtain the pre-product of the water reducer;

[0034] 2) 1 mol of the water reducer pre-product obtained in step 1) and 6 mol of 9-(p-hydroxymethyl)phenylcarbazole with fluorescent properties were subjected to an esterification reaction for 4 hours under the action of 0.03 mol of p-toluenesulfonic acid, and then Calcium hydroxide is used to adjust the pH value to 6.5, and water is added to obtain a fluorescent polycarboxylate water-reducer with a concentration of 50 wt % and a weight-average molecular weight of 50,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com