Photosensitive resin composition, display partition wall structure, and display device

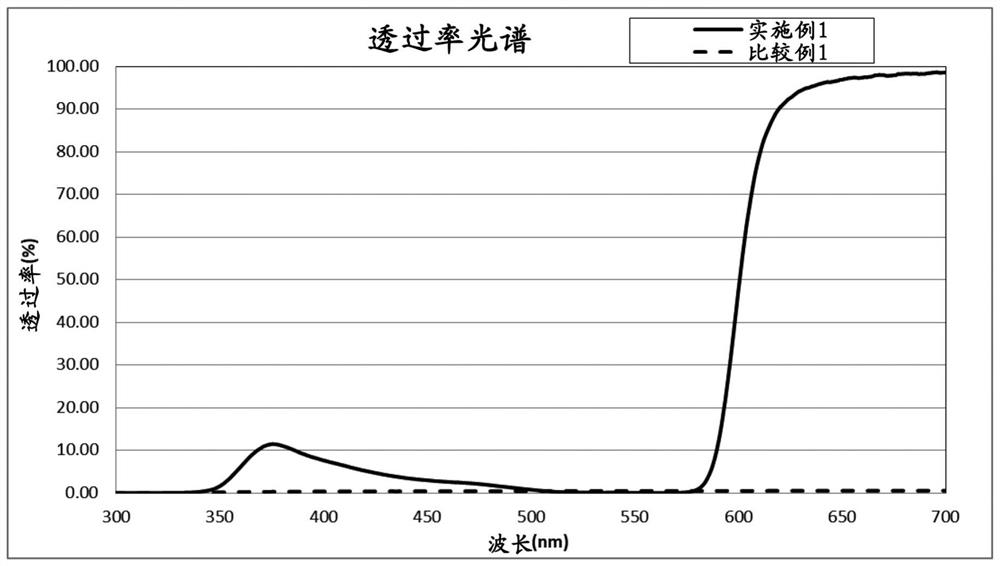

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, to achieve the effect of blocking blue light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

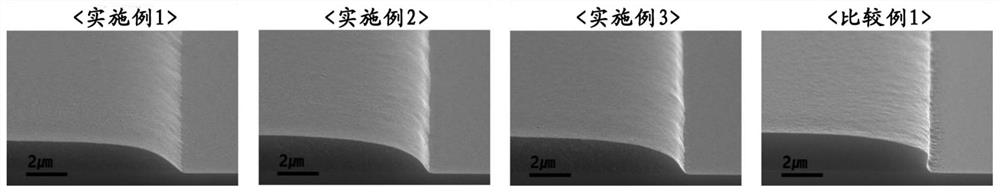

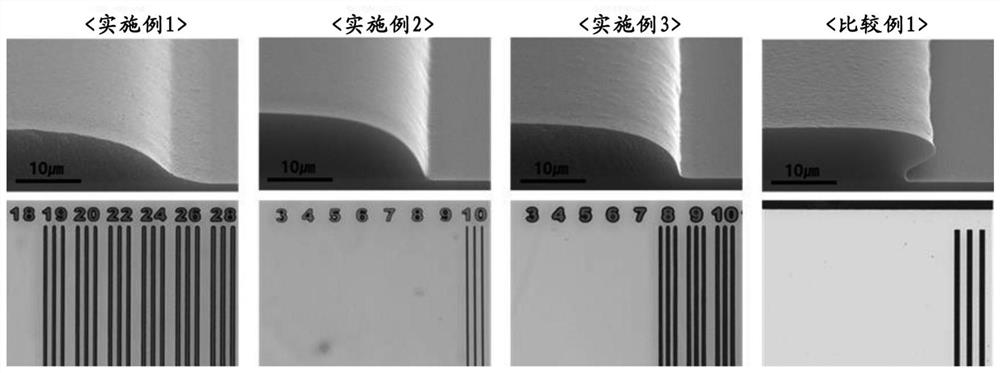

Examples

Synthetic example 1

[0103] Synthesis Example 1: Synthesis of Alkali-Soluble Resin (B-1)

[0104] In a four-necked flask, 235 g of bisphenol fluorene type epoxy monomer represented by the following chemical formula 2-1 (epoxy equivalent 235 g / eq), 110 mg of tetramethylammonium chloride, 2,6-di-tert-butyl - 100 mg of 4-methylphenol and 72.0 g of acrylic acid were dissolved by heating at 90°C to 100°C while blowing air at a rate of 25 ml / min.

[0105] [chemical formula 2-1]

[0106]

[0107] Next, the solution was gradually heated up to 120°C in a cloudy state to dissolve it. At this time, stirring was continued while confirming that the solution gradually became transparent. Heating and stirring were continued for about 12 hours until the acid value was less than 1.0 mgKOH / g. Thereafter, it was cooled to room temperature to obtain a colorless, transparent and solid bisphenol fluorene type epoxy acrylate represented by the following Chemical Formula 1-1.

[0108] [chemical formula 1-1]

[...

Synthetic example 2

[0111] Synthesis Example 2: Synthesis of Alkali-Soluble Resin (B-2)

[0112] Prepare a flask equipped with a stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen inlet. As a monomer dropping funnel, add 3,4-epoxytricyclodecan-8-yl (meth)acrylate and 3,4-epoxytricyclodecan-9-yl (meth)acrylate 40 parts by weight of the mixture mixed at a molar ratio of 50:50, 50 parts by weight of methyl methacrylate, 40 parts by weight of acrylic acid, 70 parts by weight of vinyl toluene, tert-butyl peroxy-2-ethylhexanoate 4 40 parts by weight of propylene glycol monomethyl ether acetate (PGMEA) were prepared while stirring. Here, 6 parts by weight of n-dodecanemercaptan and 24 parts by weight of PGMEA were added to the chain transfer agent dropping tank and prepared by stirring. Then, 395 parts by weight of PGMEA was added to the flask, and the atmosphere in the flask was replaced with nitrogen from air, and then the temperature of the flask was raised to 90° C. while stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com