Cu/mesoporous organic silicon oxide nanotube desulfurization adsorbent and preparation method thereof

An organic silicon oxide and nanotube technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal oxides/hydroxides, etc., can solve the problem of poor dispersion of metal active components, low mass transfer and diffusion efficiency, high price, etc. problem, to achieve the effect of enhancing mass transfer and diffusion performance, good application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

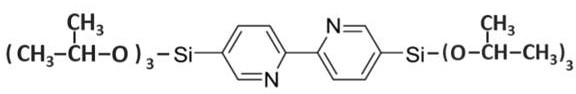

[0022] Dissolve P123 in an HCl solution with a concentration of 1M, stir to fully dissolve it to obtain a solution (1); dissolve the silicon source represented by formula (I) in ethanol, stir and dissolve it sufficiently to obtain a silicon source with a concentration of 1M solution; the silicon source solution is added dropwise to the solution (1), and a copper nitrate solution with a concentration of 0.05M is added, so that the molar ratio of the silicon source, soft template agent, and metallic copper in the solution system is 3:0.8:1, Continue to stir for 8 hours; transfer the obtained mixture into a stainless steel reaction kettle with polytetrafluoroethylene, react at 100°C for 24 hours, naturally cool to room temperature after the reaction, filter, and use ethanol to remove the soft template agent in the filtered product The reflux extraction obtained the Cu / mesoporous organosilica nanotube desulfurization adsorbent of this embodiment, wherein Cu accounted for 6.4 wt% of...

Embodiment 2

[0024] Dissolve P123 in an HCl solution with a concentration of 1.5M, stir to fully dissolve it to obtain a solution (1); dissolve the silicon source represented by formula (I) in ethanol, stir and dissolve it sufficiently to obtain a solution with a concentration of 1.2M Silicon source solution; the silicon source solution is added dropwise to the solution (1), adding a concentration of 0.05M copper nitrate solution, so that the molar ratio of silicon source, soft template agent, and metallic copper in the solution system is 3:0.8: 0.5, continue to stir for 8 hours; transfer the resulting mixture into a stainless steel reactor with polytetrafluoroethylene, react at 110°C for 20 hours, naturally cool to room temperature after the reaction, filter, and use ethanol to filter the soft template in the filtered product reflux extraction to obtain the Cu / mesoporous organosilica nanotube desulfurization adsorbent of this embodiment, wherein Cu accounts for 4.2 wt% of the mass of the a...

Embodiment 3

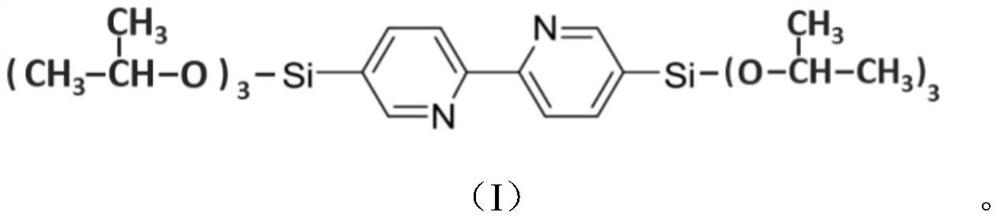

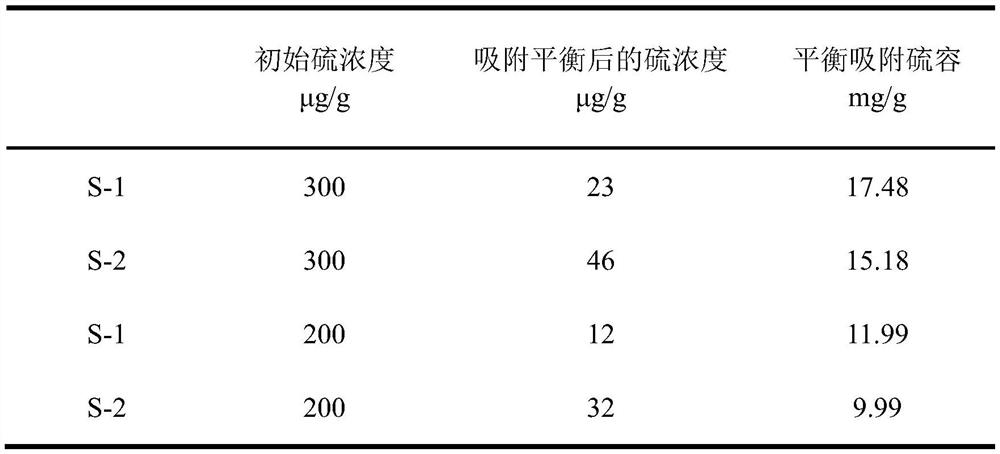

[0026] Use thiophene, benzothiophene, dibenzothiophene, 4-methyl-dibenzothiophene, and n-hexane to prepare simulated oil, and the initial sulfur concentration is 100-300μg / g. Add the Cu / mesoporous organosilica nanotube desulfurization adsorbent prepared above to the prepared simulated oil, add 1g of adsorbent per 100ml of simulated oil, place it in a shaker at 40°C for 5h, and make the adsorption reached adsorption equilibrium. The sulfur concentration in the simulated oil after adsorption equilibrium was measured by a microcoulomb sulfur analyzer, and the equilibrium adsorption sulfur capacity of the adsorbent was calculated, which is listed in Table 1. As a comparison, Cu-SBA-15 (Cu content 6wt%) prepared by the impregnation method and Cu-BTC prepared by the ordinary hydrothermal method were also subjected to the sulfur adsorption of the above simulated oil, and the results are also listed in Table 1.

[0027] As can be seen from Table 1, the Cu / mesoporous organosilica nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com