Composite lamellar material modified water-based heavy anti-corrosion coating and preparation process thereof

A preparation process and layer material technology, which is applied in the field of composite sheet material modified water-based heavy-duty anti-corrosion coatings and its preparation, can solve the problems of increased electrochemical polarizability, harsh treatment, poor shielding performance, etc., to reduce contact , Improve anti-corrosion performance, solve the effect of high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

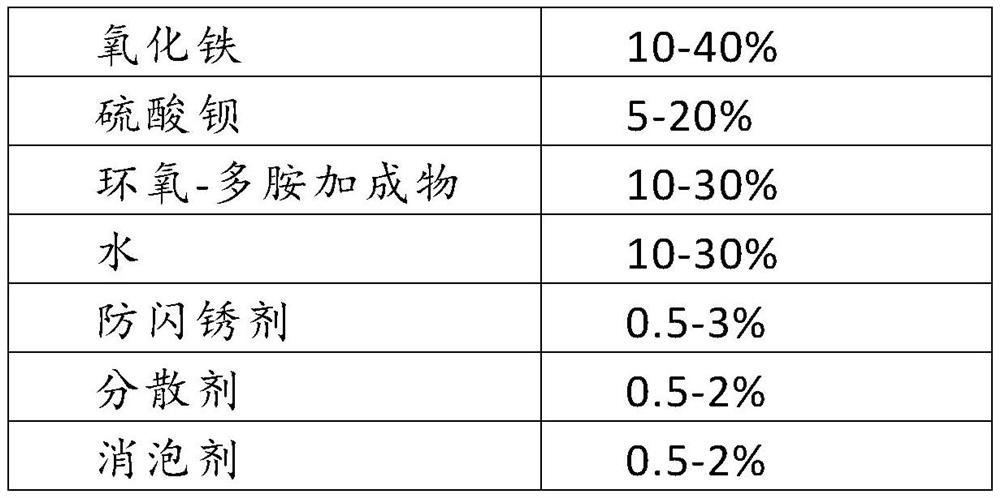

[0082]

[0083]

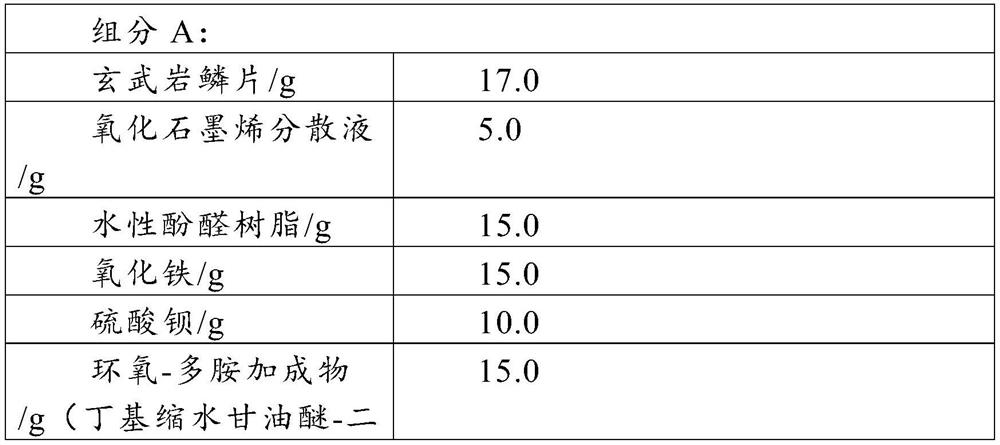

[0084] Component A: 17g of basalt flakes, 5g of graphene oxide dispersion, 15g of water-based phenolic resin, 15, iron oxide, 10g of barium sulfate, 15g of epoxy-polyamine adduct, 20g of water, 1g of anti-flash rust agent), dispersion It is composed of a mixture of 1g agent and 1g defoamer.

[0085] a. Surface modification of basalt scales to improve the dispersibility of basalt scales in the resin, and to improve the interface compatibility between basalt scales and resin;

[0086] b. Graphene oxide dispersion liquid is prepared by ultrasonic dispersion, positioning agent and pre-dispersion technology for graphene oxide.

[0087] Component B: It is composed of 48g modified epoxy resin latex, 0.5g defoamer, 1g PH regulator, 0.5g thickener and 40g water.

[0088] Among them, the epoxy latex of component B is acrylic modified epoxy latex, and its preparation process is:

[0089] a. React 100g epoxy resin and 10g surfactant (dodecylbenzene sulfonic acid) at 90℃ for 1 hou...

Embodiment 2

[0093]

[0094]

[0095] (1) A component: 18g of basalt flakes, 4g of graphene oxide dispersion, water-based phenolic resin (15g, iron oxide 10g, barium sulfate 15g, epoxy-polyamine adduct 20g, water 15g, anti-flash rust agent It is composed of a mixture of 1g, 1g of dispersant and 1g of defoamer.

[0096] a. Surface modification of basalt scales to improve the dispersibility of basalt scales in the resin, and to improve the interface compatibility between basalt scales and resin;

[0097] b. Graphene oxide dispersion liquid is prepared by ultrasonic dispersion, positioning agent and pre-dispersion technology for graphene oxide.

[0098] (2) Component B: It is composed of 45g modified epoxy resin latex, 0.5g defoamer, 1g PH adjuster, 0.5g thickener and 40g water.

[0099] Among them, the epoxy latex of component B is acrylic modified epoxy latex, and its preparation process is:

[0100] a. React 100g epoxy resin and 10g surfactant (dodecylbenzene sulfonic acid) at 90℃ for 2 hours, add ...

Embodiment 3

[0104]

[0105]

[0106] (1) Component A: 19g of basalt flakes, 3g of graphene oxide dispersion, 15g of water-based phenolic resin, 15g of iron oxide, 10g of barium sulfate, 20g of epoxy-polyamine adduct, 15.0g of water, anti-flash rust agent It is composed of a mixture of 1g, 1g of dispersant and 1g of defoamer.

[0107] a. Surface modification of basalt scales to improve the dispersibility of basalt scales in the resin, and to improve the interface compatibility between basalt scales and resin;

[0108] b. Graphene oxide dispersion liquid is prepared by ultrasonic dispersion, positioning agent and pre-dispersion technology for graphene oxide.

[0109] (2) B component: It is composed of 45g modified epoxy resin latex, 0.5g defoamer, 1g PH adjuster, 0.5g thickener and 40g water.

[0110] Among them, the epoxy latex of component B is acrylic modified epoxy latex, and its preparation process is:

[0111] a. React 100g epoxy resin and 10g surfactant (dodecylbenzene sulfonic acid) at 90℃ f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com