C chromium-free semi-organic insulating coating suitable for Bi-containing ultrahigh magnetic induction oriented silicon steel without bottom layer

A technology of insulating coating and oriented silicon steel, applied in epoxy resin coating, coating, device for coating liquid on the surface, etc. It can solve the problems of poor bottom layer and easy falling off without considering the substrate, and achieve excellent insulation and welding performance. , The effect of good coating adhesion and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

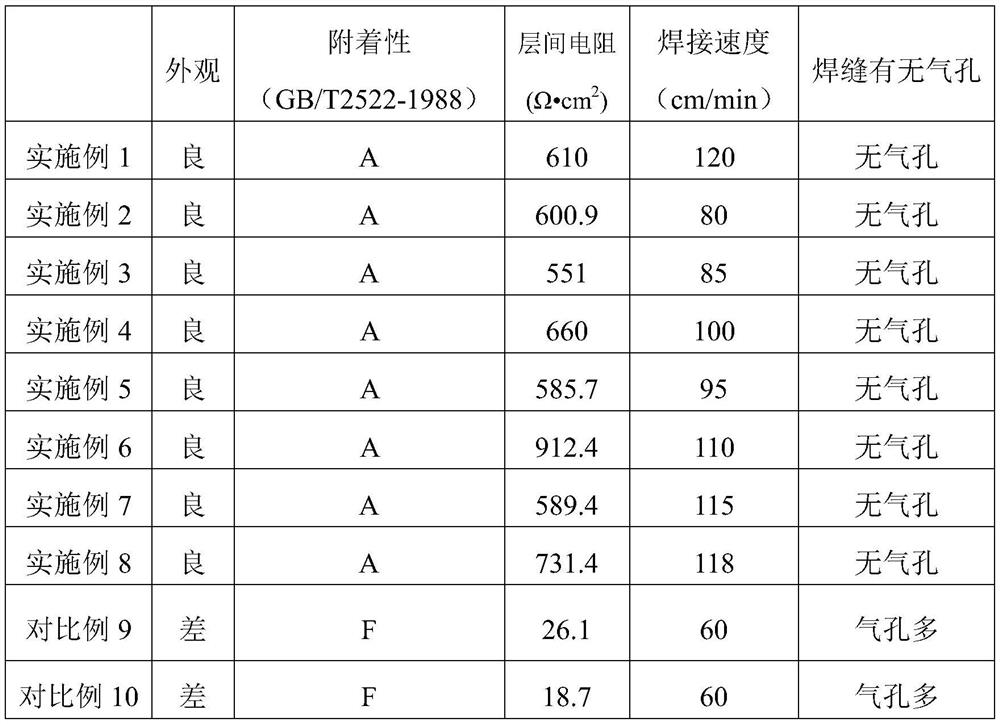

Examples

Embodiment 1

[0032] The raw materials of the chrome-free semi-organic insulating coating suitable for the Bi-containing ultra-high magnetic induction oriented silicon steel 1 without bottom layer include 22% magnesium phosphate aqueous solution (in the phosphate aqueous solution, the phosphate content is 33%), 8% colloidal silica, 50% acrylic resin and 2.5% alumina, and the balance is water.

[0033] The above-mentioned raw materials are mixed to obtain a Bi-containing ultra-high magnetic induction grain-oriented silicon steel 1 suitable for no bottom layer.

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, the difference is:

[0036] The raw materials of the chromium-free semi-organic insulating coating suitable for the Bi-containing ultra-high magnetic induction oriented silicon steel 2 without bottom layer include 20% magnesium phosphate aqueous solution (in the magnesium phosphate aqueous solution, the magnesium phosphate content is 33%), 8% Colloidal aluminum oxide, 52% polyamideimide organic resin and 3.5% calcium oxide, and the balance is water.

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 1, the difference is:

[0039] The raw materials of the chromium-free semi-organic insulating coating suitable for the Bi-containing ultra-high magnetic induction oriented silicon steel 3 without bottom layer include 19% magnesium phosphate aqueous solution (in the magnesium phosphate aqueous solution, the magnesium phosphate content is 33%), 6% Colloidal titanium dioxide, 49% epoxy resin and 2% aluminum oxide, the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com