Electrode of lithium ion battery, and lithium ion battery

A lithium-ion battery and electrode technology, applied in the field of lithium-ion batteries, can solve the problems of reducing the compacted density, increasing the specific surface area, reducing the initial efficiency of materials, etc., and achieving the effect of stable conductivity and reduced power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] In one embodiment, the electrode of the lithium-ion power battery of the present disclosure can be prepared by the following method: mixing different contents of the first lithium salt with the electrode active material and the first solvent to prepare slurry containing the first lithium salt with different concentrations material; coating the above-mentioned slurry containing the first lithium salt with different concentrations on the surface of the current collector; and then drying, rolling, die-cutting and punching to obtain the electrode sheet.

[0036] The present disclosure is not limited to the first solvent for preparing the slurry, which can be a conventional choice in the art, for example, it can be one or more of N-methylpyrrolidone, dimethylformamide, methyl acetate and tetrahydrofuran.

[0037] The present disclosure has no limitation on the way the slurry is coated on the surface of the current collector, and it can be a conventional operation in this fiel...

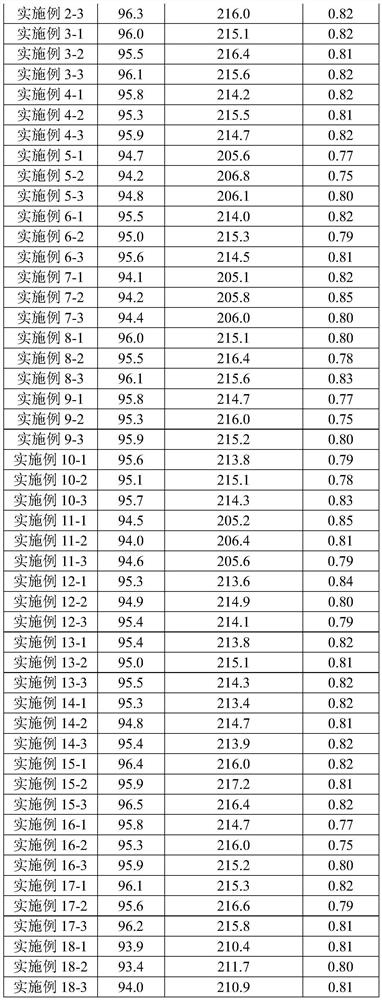

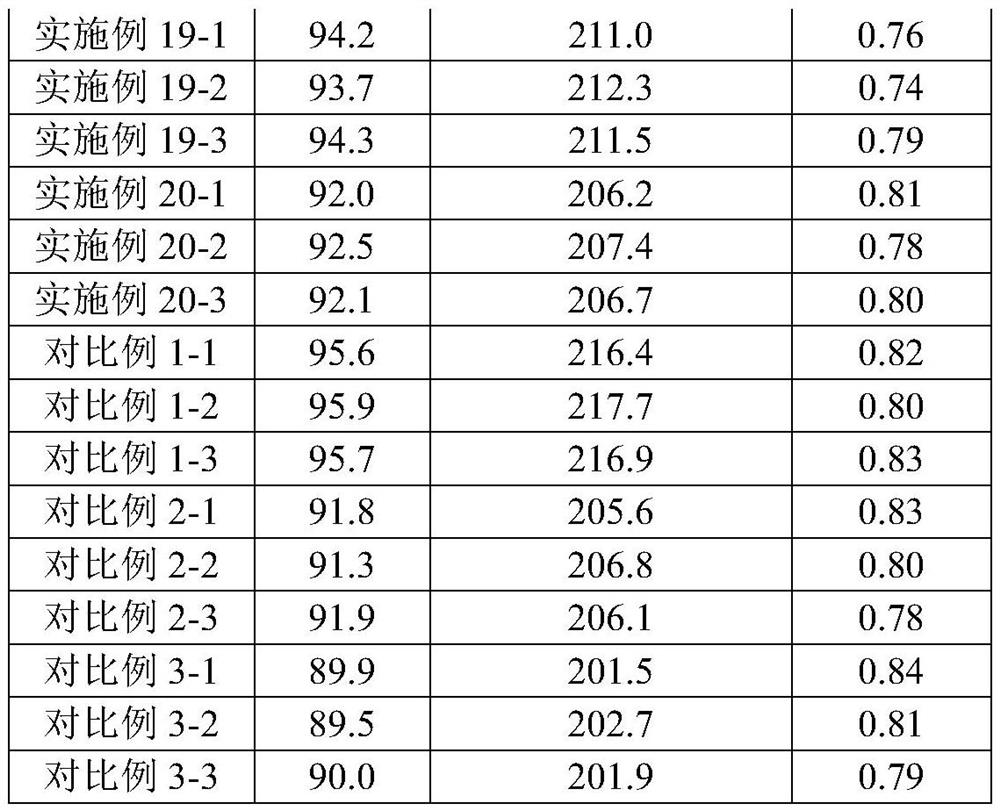

Embodiment 1

[0049] In this example, the diaphragm of the lithium-ion power battery is a polyethylene PE diaphragm with a thickness of 12 μm, the second solvent in the electrolyte is ethylene carbonate / ethyl methyl carbonate (volume ratio 5:5), and the second lithium salt is LiPF 6 , the cathode has a single-layer active material, and the anode has two layers of active material sublayers; wherein, the preparation method of the anode is as follows:

[0050] Take anode graphite and SBR (styrene-butadiene rubber), CMC (sodium carboxymethyl cellulose) and SP (conductive agent) for homogenization at a weight ratio of 95:2.5:1.5:1, add water to control the solid content to 45-55% , the viscosity is 2000-4000mpa s, after the stirring is completed, the anode slurry is passed into the upper chamber;

[0051] Take anode graphite and SBR (styrene-butadiene rubber), CMC (sodium carboxymethyl cellulose) and SP (conductive agent) and LiPF 6 (The first lithium salt) is homogenized at a weight ratio of 9...

Embodiment 2

[0054] Adopt the method for embodiment 1 to prepare lithium-ion power battery, difference is only: in the slurry preparation that passes into lower cavity, get anode graphite and SBR (styrene-butadiene rubber), CMC (sodium carboxymethyl cellulose), SP (conductive agent) and LiPF 6 (Lithium salt) Homogenize at a weight ratio of 93:2.5:1.5:1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com