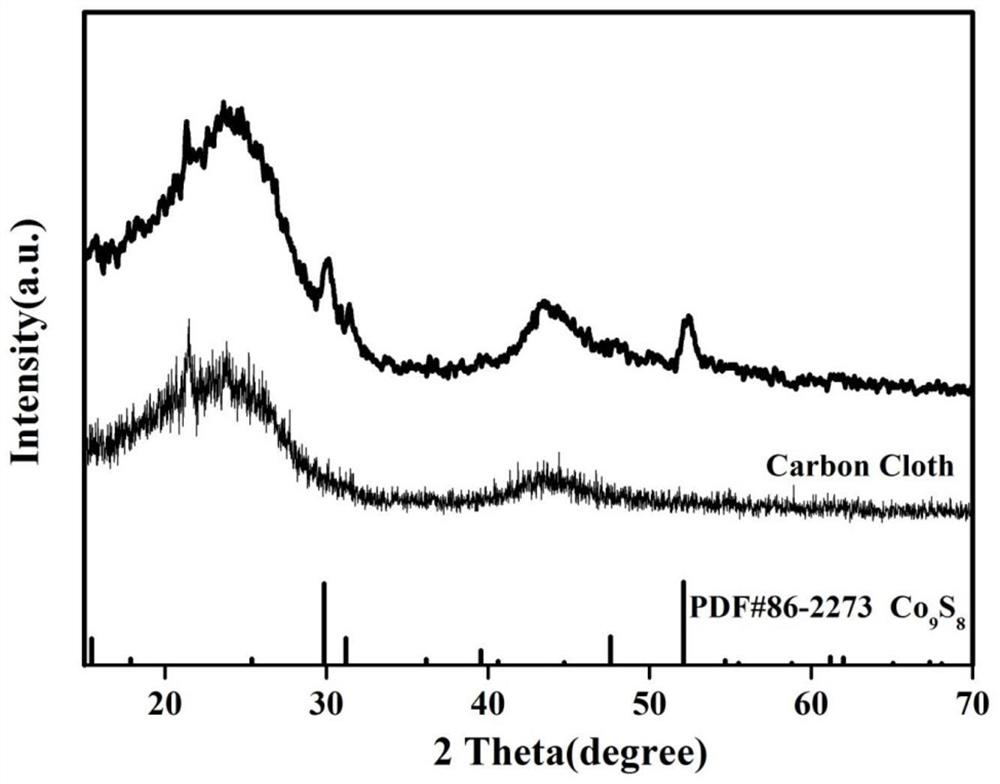

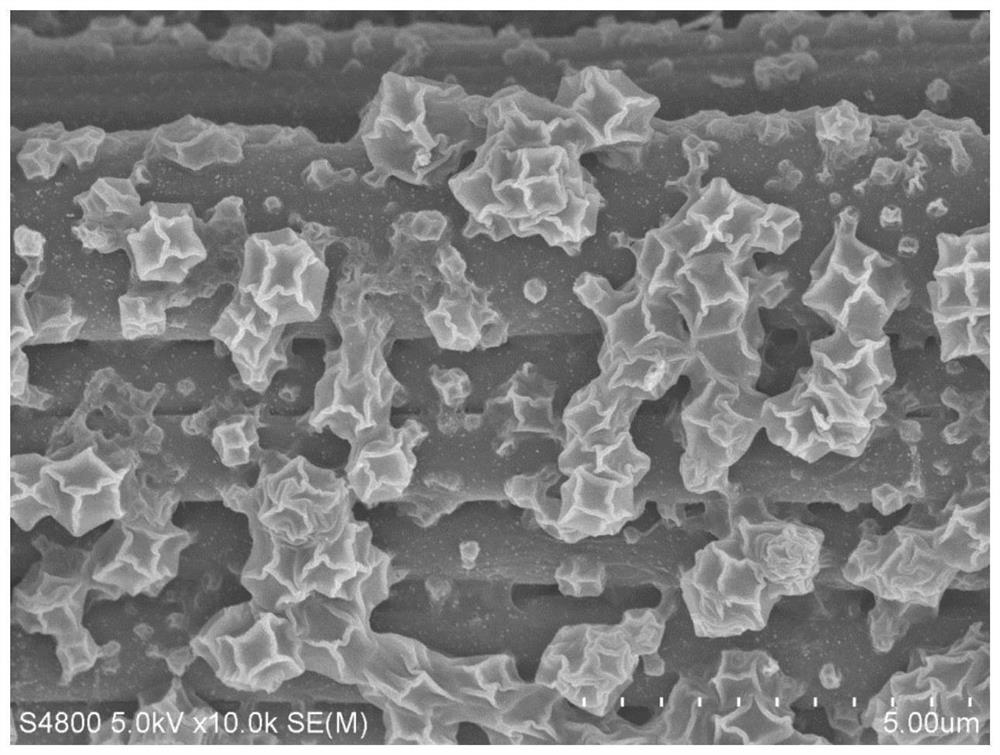

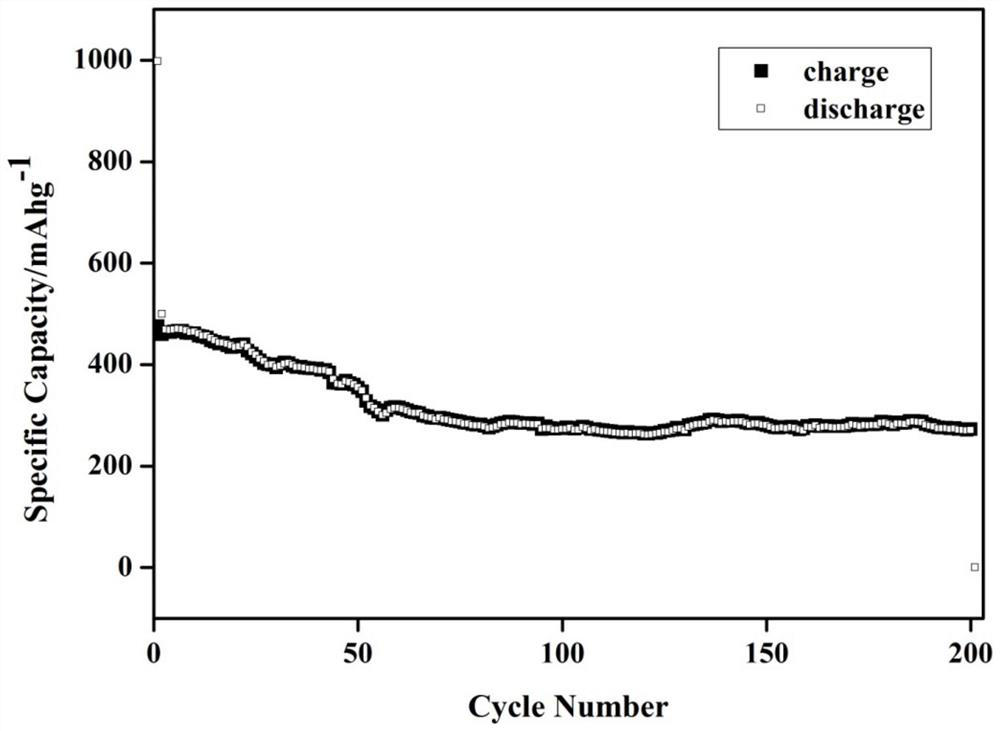

Wrinkled polyhedral cobalt sulfide electrode material and preparation method thereof

A technology of electrode materials and polyhedrons, applied in the field of electrochemistry, can solve problems such as difficult acquisition of raw materials and complex operation steps of synthesis methods, and achieve the effects of reducing production steps, improving electrical conductivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a wrinkled polyhedral cobalt sulfide electrode material of the present invention comprises the following steps,

[0029] Step 1, dissolve cobalt acetate tetrahydrate and thiourea in ethanol to obtain solution A; in solution A, Co 2+ and S 2- The molar ratio is 1:(0.5-0.7);

[0030] Step 2, the 2-methylimidazole that concentration is 0.4-0.8mol / L joins in the solution A, makes mixed solution; The volume ratio of solution A and 2-methylimidazole aqueous solution is (30-40):(10- 15);

[0031] Step 3, adding carbon cloth to the mixed solution, and heating for reaction;

[0032] In step 4, after the reaction is completed, the carbon cloth is taken out, washed and dried to obtain a cobalt sulfide electrode material in the shape of a wrinkled polyhedron.

[0033] In the present invention, cobalt sulfide is grown on the surface of carbon cloth by using carbon cloth as a self-supporting matrix in the preparation process. In the preparation process of...

Embodiment 1

[0037] 1) Dissolve cobalt acetate tetrahydrate and thiourea in anhydrous ethanol with a cobalt source and sulfur source molar ratio of 1:0.5, and magnetically stir at 700r / min for 20min to obtain a clear solution A;

[0038] 2) 2-Methylimidazole was added to deionized water, the concentration of the prepared solution was 0.4mol / L, and magnetic stirring was carried out for 20 minutes to obtain a clear solution B; the volume ratio of absolute ethanol to 2-Methylimidazole aqueous solution was 30mL:10mL;

[0039]3) Mix solution A and solution B into a polytetrafluoroethylene-lined hydrothermal reaction kettle, add pretreated carbon cloth at the same time, place it in an oven for heat treatment; the temperature of heat treatment rises from room temperature to 90 ℃, the heating reaction time is 10h; the filling degree of the mixed solution and the pretreated carbon cloth in the hydrothermal reactor is 40%. The pretreatment of the carbon cloth was ultrasonicated with acetone for 2 ho...

Embodiment 2

[0045] 1) Dissolve cobalt acetate tetrahydrate and thiourea in anhydrous ethanol with a cobalt source and sulfur source molar ratio of 1:0.55, and magnetically stir at 700r / min for 20min to obtain a clear solution A;

[0046] 2) Add 2-methylimidazole to deionized water, prepare the solution at a concentration of 0.5mol / L, and stir magnetically for 20 minutes to obtain a clear solution B; the volume ratio of absolute ethanol to 2-methylimidazole aqueous solution is 32mL:11mL;

[0047] 3) Mix solution A and solution B into a polytetrafluoroethylene-lined reaction kettle, add pretreated carbon cloth at the same time, place it in an oven for heat treatment; the temperature of heat treatment rises from room temperature to 100°C, The heating reaction time is 8 hours; the filling degree of the mixed solution and the pretreated carbon cloth in the hydrothermal reactor is 45%. The pretreatment of the carbon cloth was ultrasonicated with acetone for 3 hours, then the carbon cloth was ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com