Method for preparing carbon-loaded nano high-entropy alloy particle composite material

A technology of high-entropy alloys and composite materials, which is applied in the field of preparation of carbon-supported nano-high-entropy alloy particle composite materials, can solve the problems of high price and restrictions on the research and application of nano-high-entropy alloys and their composite materials, and achieve low cost, The effect of the simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

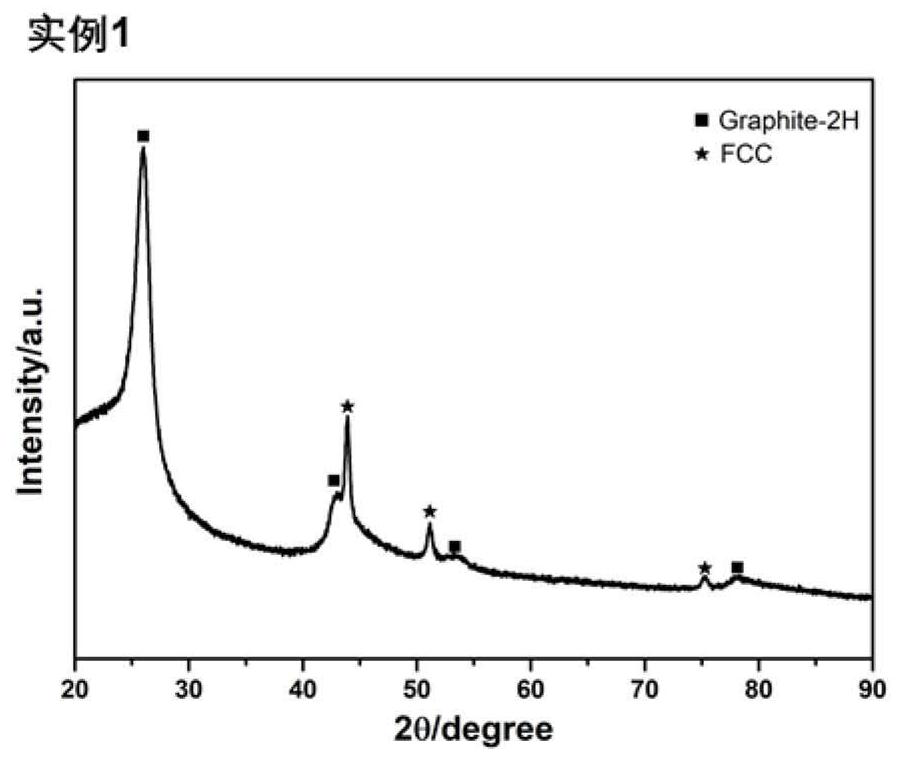

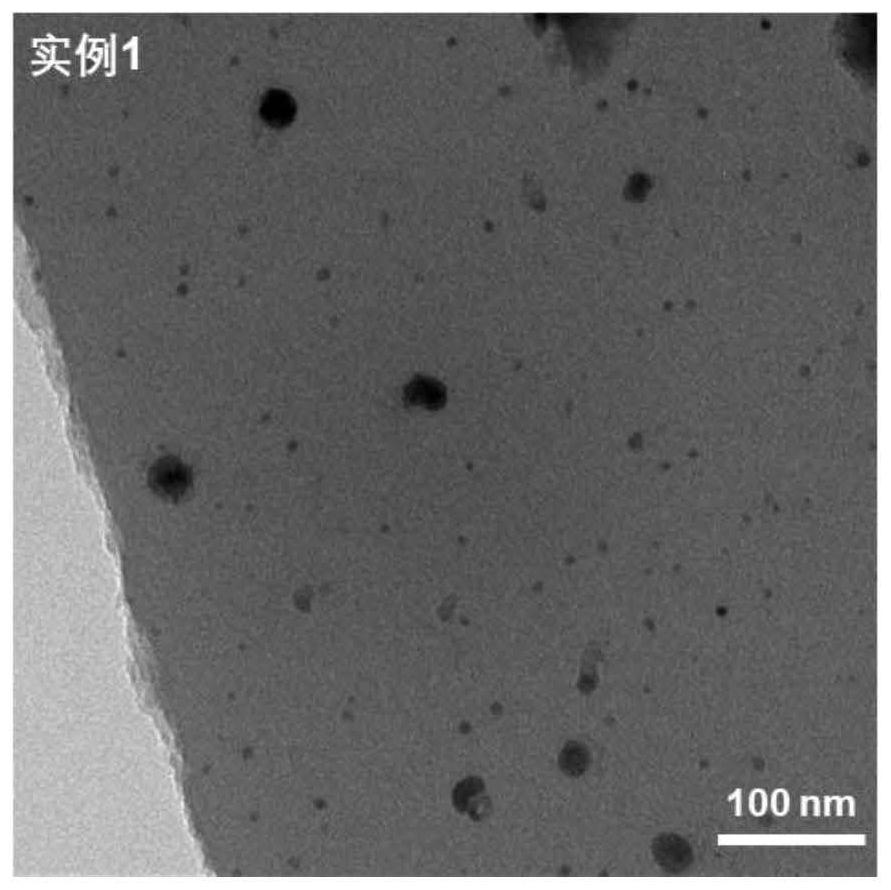

[0033] A method for preparing a carbon-loaded nano high-entropy alloy particle composite material, comprising the following steps: (1) citric acid is dissolved in water at a concentration of 0.01g / mL, glycerin is added according to 6 times the molar weight of citric acid, and heated at 90°C Obtain uniform transparent mixed solution 1 under stirring; (2) add the nitrate of Al, Fe, Co, Ni, Cu one by one in mixed solution 1 according to 0.02 of citric acid molar weight, wherein Al, Fe, Co, Ni, The molar ratio of Cu is 1:1:1:1:0.8, and the mixed solution 2 is obtained by stirring; (3) the mixed solution 2 is stirred at 300° C. for 1 hour to obtain an organic network precursor containing multiple metal ions; (4) the precursor In a hydrogen atmosphere, the temperature was raised to 900° C. at 5° C. / min, held for 2 hours, and a high-temperature reduction reaction was carried out to obtain a carbon-supported nano high-entropy alloy particle composite material. The main components of t...

Embodiment 2

[0035] A preparation method of carbon-loaded nanometer high-entropy alloy particle composite material, comprising the following steps: (1) oxalic acid is dissolved in ethanol according to a concentration of 2g / mL, polyethylene glycol is added according to 2 times the molar weight of oxalic acid, and at 80 Obtain uniform and transparent mixed solution 1 under stirring under ℃; (2) add the isopropoxide of Mg, Al, Fe, Ni, Cu, Ti one by one in mixed solution 1 according to 0.02 of the molar weight of oxalic acid, wherein Mg, Al, The molar ratio of Fe, Ni, Cu, and Ti is 0.5:0.5:1:1:0.5:0.3, stirring to obtain mixed solution 2; (3) stirring mixed solution 2 at 250°C for 24 hours to obtain an organic network precursor containing multiple metal ions (4) Raise the temperature of the precursor to 1200°C at 3°C / min in a hydrogen-argon mixed gas atmosphere, keep it warm for 12 hours, and perform a high-temperature reduction reaction to obtain a carbon-supported nano-high-entropy alloy part...

Embodiment 3

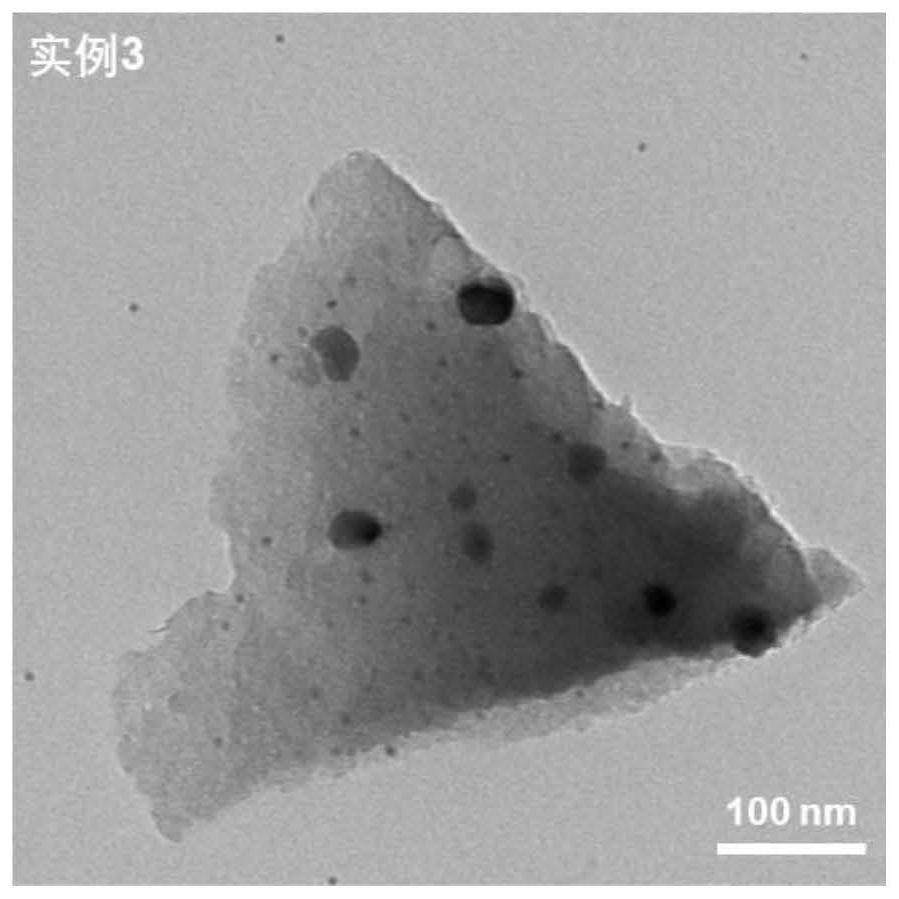

[0037] A preparation method of carbon-supported nanometer high-entropy alloy particle composite material, comprising the following steps: (1) malic acid is dissolved in water according to the concentration of 5g / mL, ethylene glycol is added according to 10 times of the molar weight of malic acid, and at 70 Obtain uniform and transparent mixed solution 1 under stirring at ℃; (2) add the nitrates of Mg, Al, Fe, Ni, Co one by one in mixed solution 1 according to 0.05 of the molar weight of malic acid, wherein Mg, Al, Fe, Ni , the molar ratio of Co is 0.5:1:1:1:1, stirring to obtain a mixed solution 2; (3) stirring the mixed solution 2 at 100°C for 8 hours to obtain an organic network precursor containing multiple metal ions; (4) mixing The precursor was heated up to 700°C at 20°C / min in an argon atmosphere, and kept for 4 hours for a high-temperature reduction reaction to obtain a carbon-supported nano-high-entropy alloy particle composite. The transmission electron microscope ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com