Broad-spectrum aflatoxin adsorption column filling material and preparation method thereof

A technology of aflatoxin and filling material, applied in the field of composite materials, can solve the problems of low degradation and detoxification ability, lack of sustainable utilization, low reuse rate, etc., and achieve good removal ability, good ability to absorb aflatoxin, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 50 mg of zirconium tetrachloride, 70 mg of 1,2,4,5-phenylcarboxybenzene, and 2,700 mg of benzoic acid in a beaker, add DMF 32 mL, and ultrasonically disperse and mix for 15 minutes to prepare a mixed solution;

[0045] Add about 100mg of melamine sponge to the above mixed solution and then ultrasonicate for 15min to form a mixture, pour the mixture into the reaction kettle, and react for 12h at 120°C;

[0046]After the reaction is completed, take out the melamine sponge and wash it twice with DMF, then put the melamine sponge into the reconfigured mixed solution for reaction, repeat the above steps to make the reaction 6 times in total;

[0047] Then the melamine sponge was taken out, washed twice with methanol, and dried at 60° C. for 12 hours to obtain the filling material of the zirconium-containing metal-organic framework material.

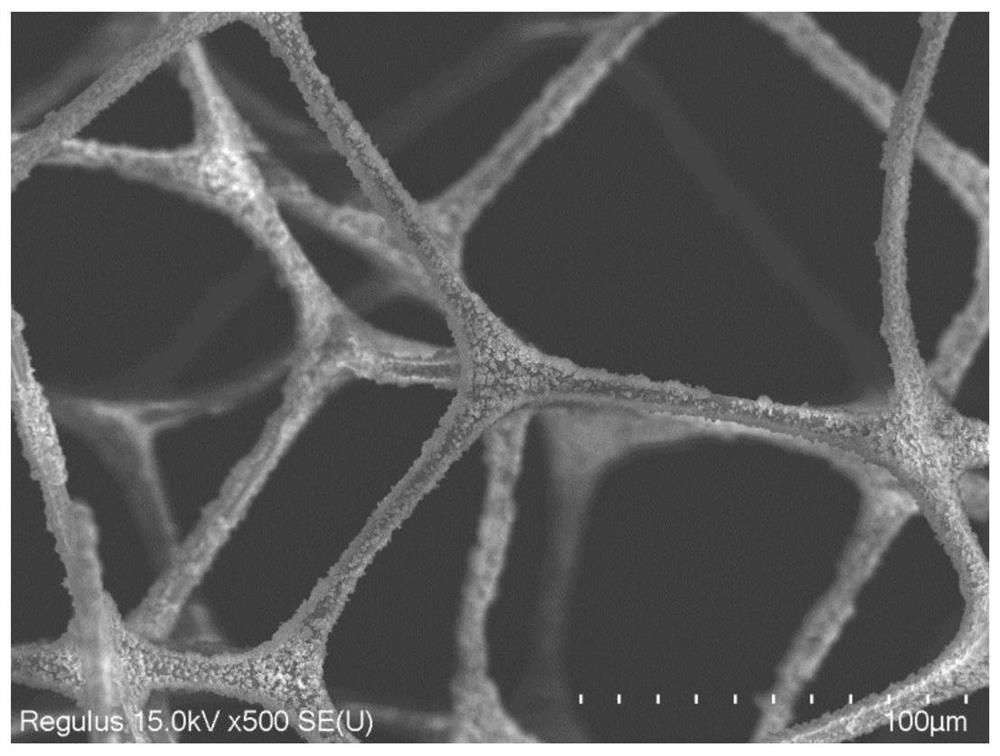

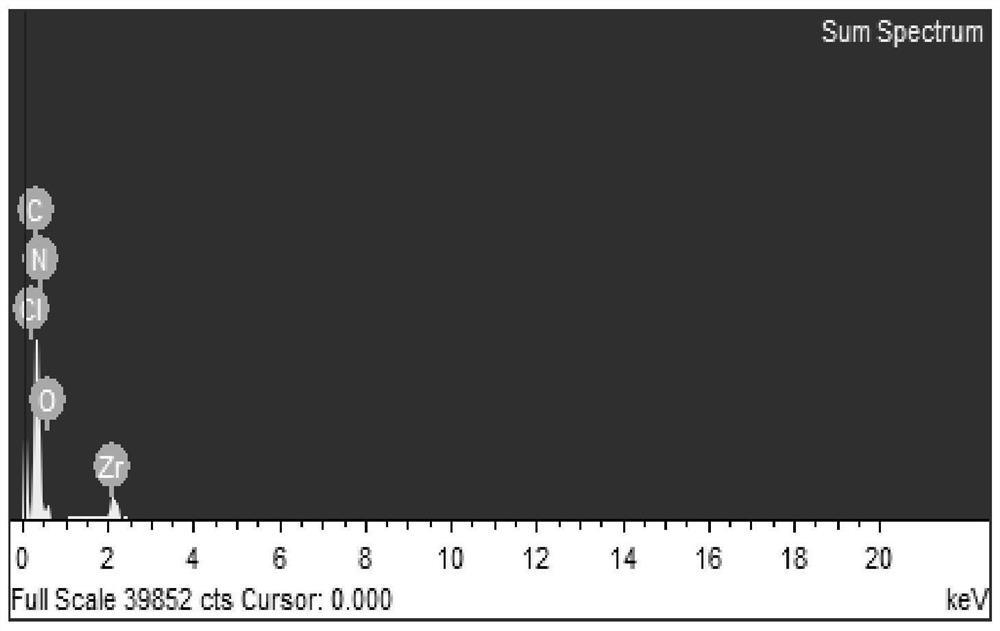

[0048] Scanning electron microscopy analysis and comparison of zirconium metal organic framework filling materials, such as figu...

Embodiment 2

[0051] Filling materials have to be used repeatedly for effect experiments:

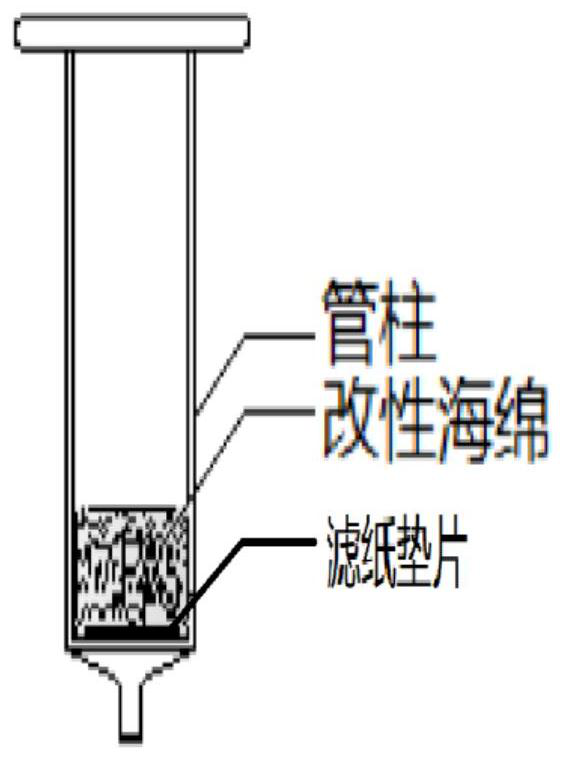

[0052] Configure aflatoxin B1 (50uM) to be diluted with ultrapure water, take 3 mg of filling material to fill an empty solid-phase extraction column, activate it with deionized water in advance, use 1mL aflatoxin B1 to pass into the column, collect the filtrate, and measure the absorbance of the filtrate . Compare before and after filtering Figure 4 ,Depend on Figure 4 It can be seen that the filling material has a good effect of releasing aflatoxin B1. It can be seen that after repeating the above experiment for 5 times of repeated filtration, the removal rate has no obvious change substantially each time. Figure 5 , indicating that the filling material has a good reuse rate.

[0053] Application experiment of filling material to remove aflatoxin B1 in water:

[0054] Configure 50uM aflatoxin B1 solution, dilute with tap water, river water, rainwater, and field water, mix thoroughly, and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com