Production technology process of raw virgin high-oleic-acid peanut oil

A production technology, high oleic acid technology, applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of reducing peanut oil nutrition, safety quality, fragrance reduction, safety hazards, etc., to avoid fragrance and nutrition Loss of ingredients, fast cooling and condensing fragrance, ensuring high-end quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0050] Select high-quality high-oleic acid peanuts and choose fertile land rich in organic matter to plant high-oleic acid peanuts. The site is located in Shizilu Town, Junan County. At the end of autumn and early winter, plow deeply and plow 25-30 cm. For heavy clay soil, press 15-20 cubic meters of river sand or phosphorus-containing weathered stone per mu; for sandy soil, press 15-20 cubic meters per mu. Silt or clay to improve soil. After deep plowing, 2,500 kg of high-quality decomposed organic fertilizer (with a nitrogen content of more than 0.2%) is applied at one time, together with 50 kg of superphosphate and 20 kg of potassium sulfate compound fertilizer. When the 5cm ground temperature reaches an average of above 15°C within 5 days, and the soil water content accounts for about 70% of the maximum water holding capacity in the field, sow the seeds. After sowing, dilute with 100mL of 72% Dour EC with water per mu, and spray the ground evenly , After testing, the olei...

experiment example 2

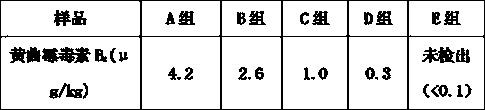

[0052] The present invention utilizes the ozone produced by the ozone generator to physically remove the aflatoxin from the peanut kernel raw material in the raw material temporary storage tank. 1 The degradation effect is shown in the table below:

[0053]

[0054] Note: Group A: peanut kernels without ozone treatment.

[0055] Group B: peanut kernels with the ozone generator gear set at 89mg / L ozone concentration and 2L / min flow rate, and the treatment time being 20min.

[0056] Group C: peanut kernels with the ozone generator gear set at an ozone concentration of 89mg / L and a flow rate of 2L / min, and a processing time of 30min.

[0057] Group D: peanut kernels with the ozone generator gear set at 89 mg / L of ozone concentration and 4 L / min of flow rate, and the treatment time being 20 min.

[0058] Group E: peanut kernels with the ozone generator gear set at 89 mg / L of ozone concentration and 4 L / min of flow rate, and the treatment time being 30 min.

[0059] It can be...

experiment example 3

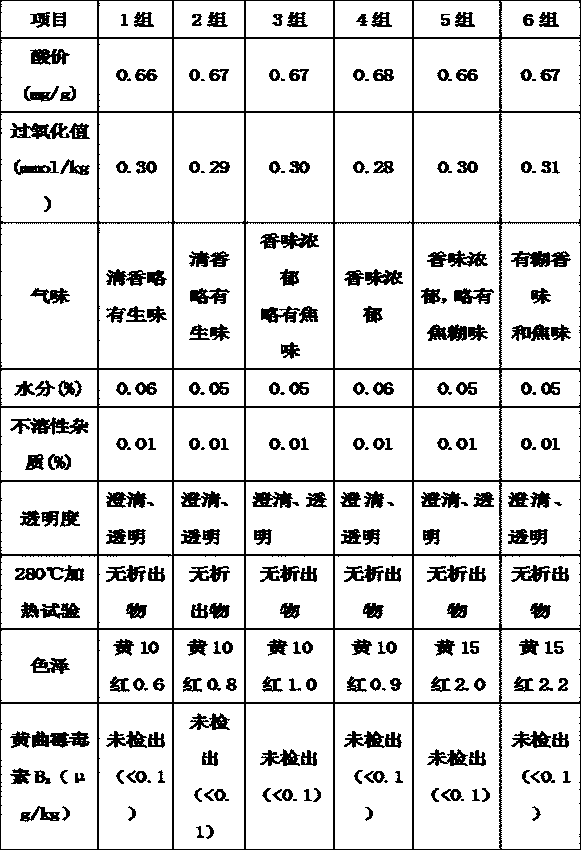

[0061] In the production process of the present invention, the production technology and product quality detection results of a kind of raw virgin high oleic peanut oil produced by screening and classification and without screening and classification are shown in the following table:

[0062]

[0063] It can be seen from the above table that the acid value, peroxide value, moisture and insoluble impurities of the peanut oil obtained after screening and grading are all lower than those without screening and grading. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com