Heat-coupled phenol-ammonia wastewater treatment device and method

A heat coupling and wastewater treatment technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problem of not necessarily meeting the heat demand of individual phenol towers, lack of backup external heating for phenol towers and water towers, The problem of high ammonia content in the steam at the top of the deammonization tower can achieve the effect of improving heat availability, low ammonia content, and reducing equipment materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

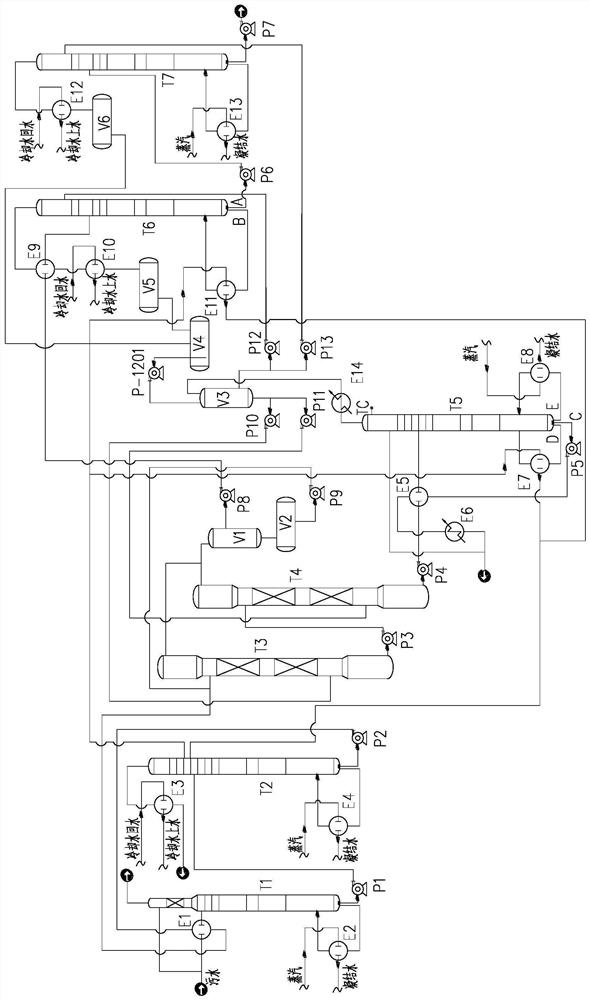

[0047] Example 1: Such as figure 1 As shown, the steam produced by the ammonia removal tower T2 first exchanges heat with the reboiler of the previous solvent recovery tower T6, and the condensed water after the heat exchange is mixed with the steam and then passes through a reboiler E7 of the water tower T5. After the second heat exchange, the condensate after the second heat exchange returns to the side line extraction position or the next layer of the extraction position in the ammonia removal tower T2.

Embodiment 2

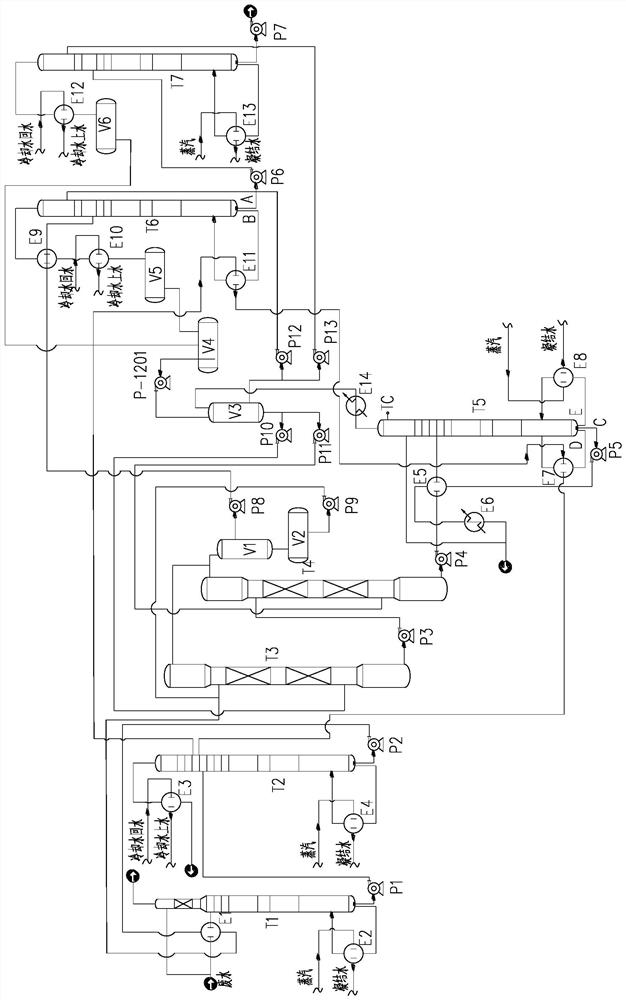

[0048] Example 2: Such as figure 2 As shown, the steam produced by the ammonia removal tower T2 is divided into two streams, one for heat exchange with the reboiler of the previous solvent recovery tower T6, the other for heat exchange with a reboiler E7 of the water tower T5, and the two respectively The condensate after heat exchange through the reboiler E7 is merged back to the side line extraction position or below the extraction position in the ammonia removal tower T2.

[0049] The crude ammonia gas is discharged from the top of the T2 tower of the ammonia removal tower, the temperature is 135~145℃, the crude ammonia gas is condensed by cooling water through the condenser E3 of the ammonia removal tower, and the temperature is controlled at 50~80℃;

[0050] The deamination tower in the present invention is operated under pressure, the operating pressure at the top of the deamination tower is 350-500kPa(g), and the operating temperature is 135-163°C; the deammination tower re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com