Method for preparing porous ceramic from coal gangue

A technology of porous ceramics and coal gangue, which is applied in the production and application of ceramic products and ceramic materials, which can solve the problems of single function of porous ceramics and low utilization rate of coal gangue, and achieve the effect of uniform pore formation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

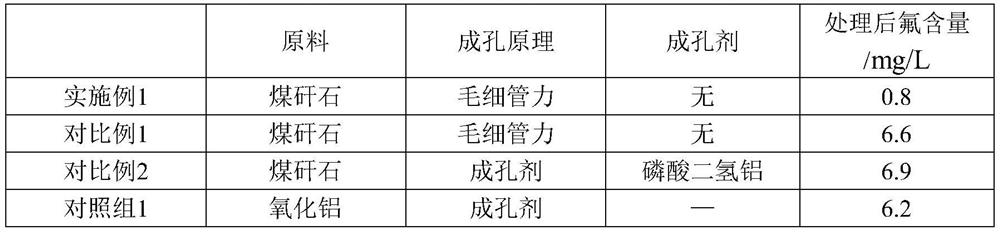

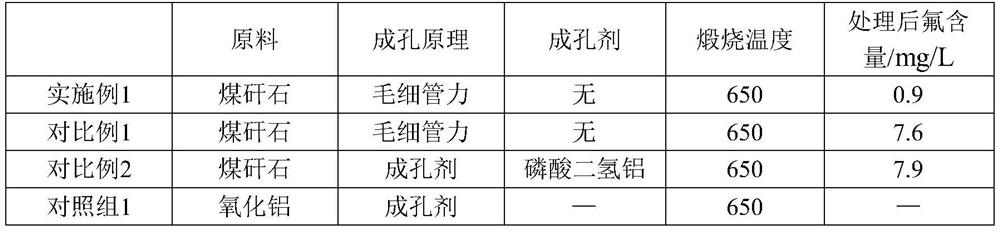

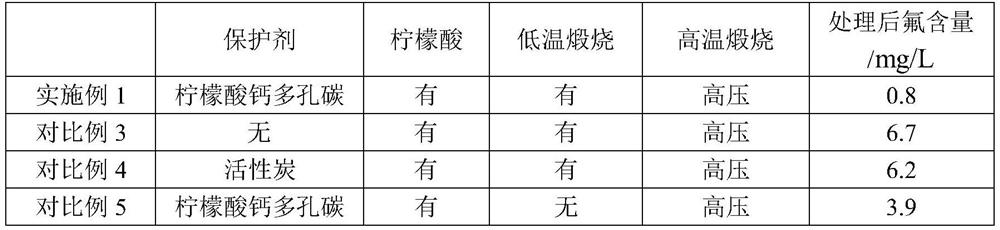

Examples

Embodiment 1

[0031] The method for preparing porous ceramics from coal gangue: it is characterized in that: comprising:

[0032] (1) Pre-treatment of acid reaction of coal gangue:

[0033] The coal gangue block is pressed into shape and calcined in an electric furnace (high-temperature tunnel kiln). When the finished product leaves the kiln, it is quickly cooled to room temperature by a quenching wind to obtain calcined gangue clinker; the calcined coal gangue clinker is subjected to dry ball milling for 48 hours. Then cross 180 mesh sieves to obtain coal gangue clinker fine powder;

[0034] Add coal gangue clinker fine powder into the hydrochloric acid solution, and stir at 85° C. for 1 hour to carry out acid leaching to obtain the acid treatment product; wherein, the mass concentration of hydrochloric acid is 7%, and the hydrochloric acid solution and coal gangue clinker fine powder The liquid-solid ratio is: 5mL / g;

[0035] (2) Pre-melting treatment of coal gangue:

[0036] The solid...

Embodiment 2

[0049] The method for preparing porous ceramics from coal gangue: it is characterized in that: comprising:

[0050] (1) Pre-treatment of acid reaction of coal gangue:

[0051] The coal gangue block is pressed into shape and calcined in an electric furnace (high-temperature tunnel kiln). When the finished product leaves the kiln, it is quickly cooled to room temperature by a quenching wind to obtain calcined gangue clinker; the calcined coal gangue clinker is subjected to dry ball milling for 48 hours. Cross 200 mesh sieves then, obtain coal gangue clinker fine powder;

[0052] Add coal gangue clinker fine powder into the hydrochloric acid solution, and stir at 95°C for 1.5 hours to carry out acid leaching to obtain the acid treatment product; wherein, the mass concentration of hydrochloric acid is 20%, and the hydrochloric acid solution and coal gangue clinker fine powder The liquid-solid ratio is: 25mL / g;

[0053] (2) Pre-melting treatment of coal gangue:

[0054] The soli...

Embodiment 3

[0069] The method for preparing porous ceramics from coal gangue: it is characterized in that: comprising:

[0070] (1) Pre-treatment of acid reaction of coal gangue:

[0071] The coal gangue block is pressed into shape and calcined in an electric furnace (high-temperature tunnel kiln). When the finished product leaves the kiln, it is quickly cooled to room temperature by a quenching wind to obtain calcined gangue clinker; the calcined coal gangue clinker is subjected to dry ball milling for 48 hours. Then cross 190 mesh sieves to obtain coal gangue clinker fine powder;

[0072] Add coal gangue clinker fine powder into the hydrochloric acid solution, and stir at 90°C for 1 hour to carry out acid leaching to obtain the acid treatment product; wherein, the mass concentration of hydrochloric acid is 15%, and the hydrochloric acid solution and coal gangue clinker fine powder The liquid-solid ratio is: 15mL / g;

[0073] (2) Pre-melting treatment of coal gangue:

[0074] The solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com