Antibacterial film as well as preparation method and application thereof

A technology of antibacterial film and pectin, which is applied in the field of antibacterial film and its preparation, can solve problems such as difficulties, and achieve the effects of excellent antibacterial property, simple preparation method, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

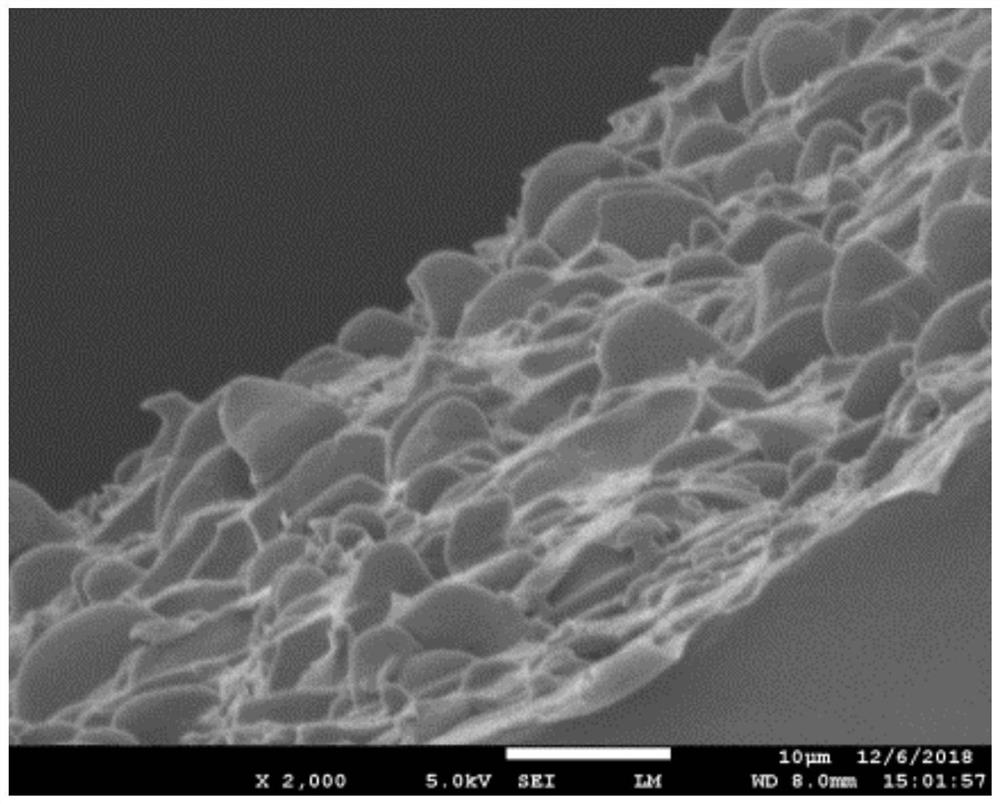

[0031] At room temperature, 2 parts by weight of low-ester pectin and 5 parts by weight of polyvinyl alcohol (type 1799) are formulated into an aqueous solution, and then 1 part by weight of glycerin, 1 part by weight of sorbitol and 1 part by weight of tannic acid are added to form a film-forming solution. The total weight is 100 parts, and the prepared film-forming solution is added dropwise on the polypropylene substrate, and baked at 60°C for 12 hours until the solution is dried to obtain the antibacterial film. It is a light yellow transparent film, which is recorded as TA1%. The scanning electron microscope results of the samples are as follows figure 1 shown by figure 1 It can be seen that after tannic acid is added in the film-forming liquid system, gel balls are formed with pectin and polyvinyl alcohol. The diameter of the gel balls is in the range of 4-10 μm, and the antibacterial film is formed by the gel balls. Its thickness is about 0.12mm.

Embodiment 2

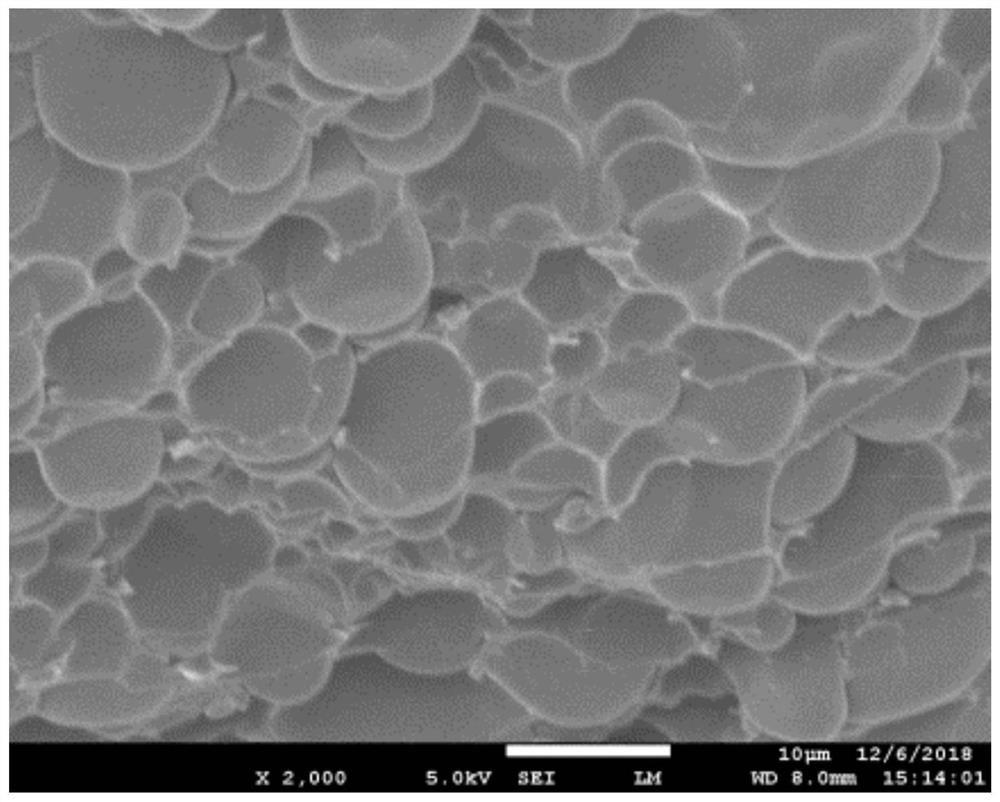

[0033] According to the same method of embodiment 1, only the quality of tannic acid is improved to 2 parts by weight, and oven dry promptly obtains described antibacterial film, is light yellow transparent film, is recorded as TA2%. The scanning electron microscope results of the samples are as follows figure 2 shown by figure 2 It can be seen that after tannic acid is added in the film-forming liquid system, it forms gel balls with pectin and polyvinyl alcohol. The diameter of the gel balls is in the range of 4-10 μm, and the antibacterial film is formed by the gel balls. About 0.12mm.

Embodiment 3

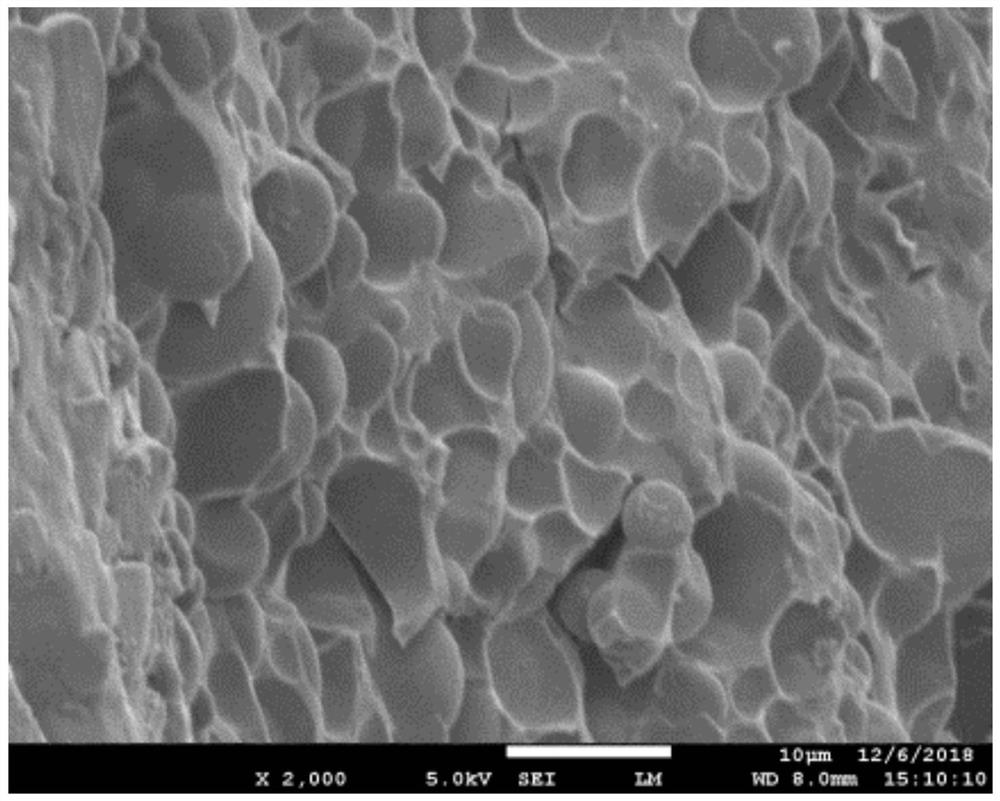

[0035] According to the same method of embodiment 1, only the quality of tannic acid is improved to 3 parts by weight, and oven dry promptly obtains described antibacterial film, is light yellow transparent film, is recorded as TA3%. The scanning electron microscope results of the samples are as follows image 3 shown by image 3 It can be seen that after tannic acid is added in the film-forming liquid system, it forms gel balls with pectin and polyvinyl alcohol. The diameter of the gel balls is in the range of 4-10 μm, and the antibacterial film is formed by the gel balls. About 0.12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com