Natural granite marble and multiple-artificial material composite high-strength adhesive

An artificial material, granite technology, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problems of decreased bonding strength, different substrates, and different properties of marble and artificial materials. To achieve good bonding strength, improve bonding effect, and promote the effect of grafting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composite high-strength adhesive of a kind of natural granite marble and various artificial materials of the present embodiment comprises the following raw materials in parts by weight:

[0025] 55 parts of graft resin, 20 parts of rosin, 3 parts of alkylene glycidyl ether, 15 parts of hydrogenated castor oil, 10 parts of silane coupling agent KH56010, 5 parts of hydroxypropyl cellulose ether, 5 parts of sodium lauryl sulfate, 10 parts of filling aid.

[0026] The preparation method of the grafted resin in this example is: mix the phenolic resin and the modified bentonite according to the weight ratio of 3:1, then add vinyl acetate, first stir at a speed of 200r / min for 15min, and then add nano Active agent, continue to stir at a speed of 100r / min for 45min, then use a proton irradiation machine to irradiate for 10min, the irradiation power is 250W, and finally send it to the refrigerator for 1h at -2°C, then take it out and return to room temperature , and then ke...

Embodiment 2

[0032] The composite high-strength adhesive of a kind of natural granite marble and various artificial materials of the present embodiment comprises the following raw materials in parts by weight:

[0033] 65 parts of grafted resin, 30 parts of rosin, 7 parts of alkylene glycidyl ether, 25 parts of hydrogenated castor oil, 20 parts of silane coupling agent KH56020, 10 parts of hydroxypropyl cellulose ether, 15 parts of sodium lauryl sulfate, Filling aid 20 parts.

[0034] The preparation method of the grafted resin of this embodiment is: mix the phenolic resin and the modified bentonite according to the weight ratio of 3:1, then add vinyl acetate, first stir at a speed of 500r / min for 25min, after the stirring is completed, add nano Active agent, continue to stir at a speed of 100r / min for 55min, then use a proton irradiation machine to irradiate for 10min, the irradiation power is 350W, and finally send it to the refrigerator for 2h at -2°C, then take it out and return to roo...

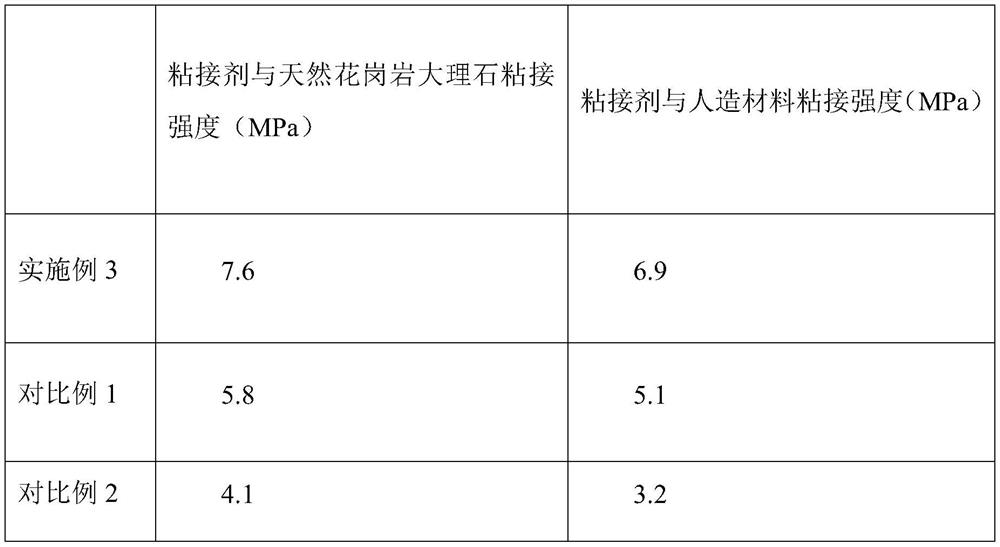

Embodiment 3

[0040] The composite high-strength adhesive of a kind of natural granite marble and various artificial materials of the present embodiment comprises the following raw materials in parts by weight:

[0041] 60 parts of graft resin, 25 parts of rosin, 5 parts of alkylene glycidyl ether, 20 parts of hydrogenated castor oil, 15 parts of silane coupling agent KH5601, 7.5 parts of hydroxypropyl cellulose ether, 10 parts of sodium lauryl sulfate, Filling aid 15 parts.

[0042] The preparation method of the grafted resin of this embodiment is: mix the phenolic resin and the modified bentonite according to the weight ratio of 3:1, then add vinyl acetate, first stir at a speed of 350r / min for 20min, after the stirring is completed, add nano The active agent was stirred at a speed of 100r / min for 50min, and then irradiated by a proton irradiation machine for 10min with a radiation power of 300W. Finally, it was sent to the refrigerator for 1.5h at a temperature of -2°C, and then it was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com