Preparation method of zinc oxide gas desulfurizing agent

A technology of desulfurizer and zinc oxide, which is applied in the removal of gas pollutants, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of low utilization rate of active components, poor vulcanization-regeneration performance of desulfurizer, etc. Achieve the effect of realizing gas-solid reaction rate and mass transfer efficiency, reducing adverse effects, excellent mechanical properties and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

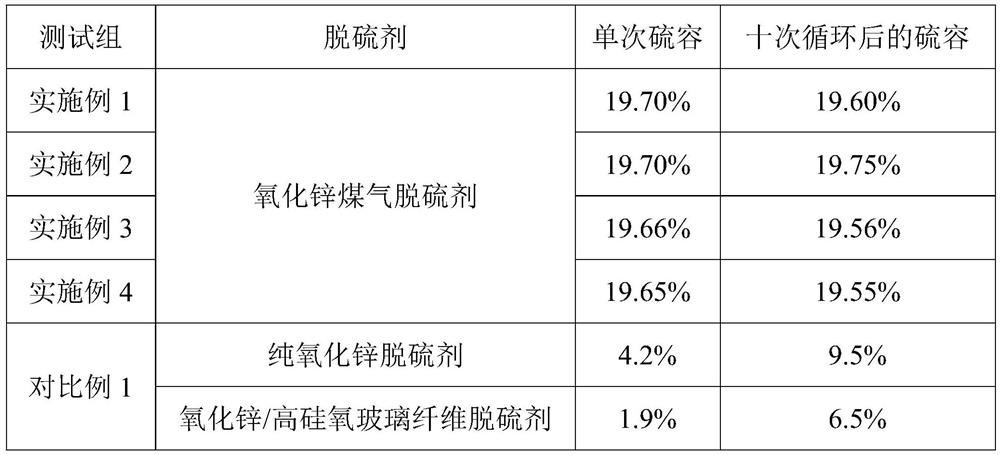

Examples

Embodiment 1

[0025] A. Preparation of three-dimensional full five-way braided pieces: four-step three-dimensional braiding technology is used to weave fiber filaments into three-dimensional full five-way knitted pieces with shaft yarns. This process is carried out on a three-dimensional knitting machine, and the number of braided yarn rows is 40 *40, at the same time discharge shaft yarns (including five-way shaft yarns and full five-way shaft yarns) in the gap formed by the cross paths of each weaving yarn, and finally form a square-section prefabricated part with a cross-sectional size of 10mm*10mm, braiding angle is 45 degrees. Among them, the axial yarn is carbon fiber filament, and the weaving yarn is high-silica glass fiber; the length, width and height of the three-dimensional woven piece are 10mm, 10mm, and 20mm, respectively;

[0026] B. Preparation of hydrothermal solution: use a certain volume of Zn(NO 3 ) 2 ·6H 2 O and 8 mL of 25% NH by volume 3 ·H 2 O is mixed with 80mL o...

Embodiment 2

[0034]A. Preparation of three-dimensional full five-way braided pieces: four-step three-dimensional braiding technology is used to weave fiber filaments into three-dimensional full five-way knitted pieces with shaft yarns. This process is carried out on a three-dimensional knitting machine, and the number of braided yarn rows is 40 *40, at the same time discharge shaft yarns (including five-way shaft yarns and full five-way shaft yarns) in the gap formed by the cross paths of each weaving yarn, and finally form a square-section prefabricated part with a cross-sectional size of 10mm*10mm, braiding angle is 45 degrees. Among them, the axial yarn is carbon fiber filament, and the weaving yarn is high-silica glass fiber; the length, width and height of the three-dimensional woven piece are 10mm, 10mm, and 20mm, respectively;

[0035] B. Preparation of hydrothermal solution: use a certain volume of Zn(NO 3 ) 2 ·6H 2 O and 8 mL of 25% NH by volume 3 ·H 2 O was prepared into 80m...

Embodiment 3

[0044] A. Preparation of three-dimensional full five-way braided pieces: four-step three-dimensional braiding technology is used to weave fiber filaments into three-dimensional full five-way knitted pieces with shaft yarns. This process is carried out on a three-dimensional knitting machine, and the number of braided yarn rows is 40 *40, at the same time discharge shaft yarns (including five-way shaft yarns and full five-way shaft yarns) in the gap formed by the cross paths of each weaving yarn, and finally form a square-section prefabricated part with a cross-sectional size of 10mm*10mm, braiding angle is 45 degrees. Among them, the axial yarn is carbon fiber filament, and the weaving yarn is high-silica glass fiber; the length, width and height of the three-dimensional woven piece are 10mm, 10mm, and 20mm, respectively;

[0045] B. Preparation of hydrothermal solution: use a certain volume of Zn(NO 3 ) 2 ·6H 2 O and 8 mL of 25% NH by volume 3 ·H 2 O was prepared into 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com