Iron-containing red mud coal-based direct reduction process and system

A red mud, direct technology, applied in the iron-containing red mud coal-based direct reduction process and system field, can solve the problems of high reduction temperature, low metal recovery rate, low metallization rate of reduced materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention is described in further detail below by specific examples.

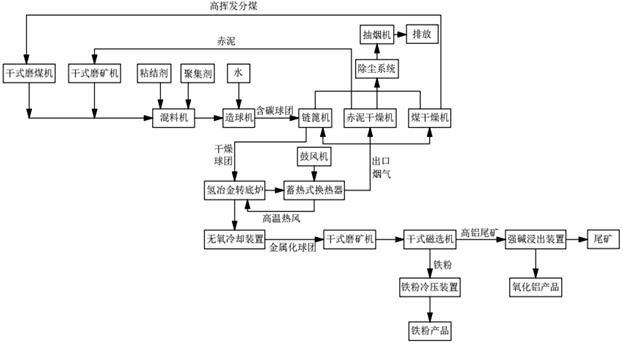

[0044] Such as figure 1 As shown, the iron-containing red mud coal-based direct reduction system includes a mixer, a pelletizer, a chain grate, a hydrogen metallurgy rotary hearth furnace, an anaerobic cooling device, a dry grinding machine, and a dry magnetic separator connected in sequence ; The mixer is also connected with a dry ore mill and a dry coal mill, and the dry ore mill and the dry coal mill are respectively connected with a red mud dryer and a coal dryer; the hydrogen metallurgy The rotary hearth furnace is also connected with a regenerative heat exchanger that provides high-temperature hot air for the hydrogen metallurgical rotary hearth furnace. The regenerative heat exchanger is connected with a blower. The dryer and the coal dryer are connected, and the outlet flue gas of the regenerative heat exchanger is used as the heat source to dry the material. The grate machine, the red m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com