Tungsten-cobalt-nickel alloy and preparation method and application thereof

A technology of nickel alloy and tungsten-cobalt, which is applied in the field of metallurgy, can solve the problems that tungsten alloy cannot satisfy the mechanical properties of elongation, reduction of area, tensile strength, and yield strength, etc., and achieve reduced solidification segregation, excellent strength, and uniform composition and structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

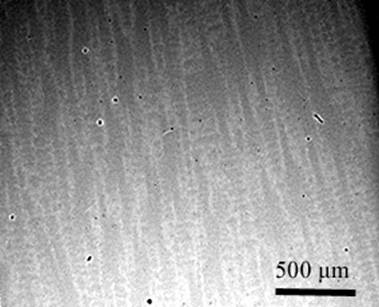

Image

Examples

Embodiment 1

[0060] This application provides a high-quality, large-density, high-tungsten, high-cobalt-nickel alloy, the chemical composition of which is 39% tungsten, 20% cobalt and 41% nickel by mass percentage;

[0061] Prepare materials according to the above alloy composition, melt and pour the alloy raw materials into electrode ingots with a diameter of 240 mm in a vacuum induction furnace;

[0062] Cut off the head and tail of the electrode ingot, and polish the surface to reveal the metallic luster; weld the auxiliary electrode and bake it in a heating furnace at 250°C for 3 hours to remove water vapor; wipe the surface of the electrode with a clean rag to clean oil and oxides after leaving the furnace and air cooling and other foreign objects;

[0063] Put the treated electrode in the vacuum consumable furnace, complete the furnace loading, centering, sealing and other operations, feed the cooling water flow rate of 650 mL / min, vacuumize to 0.15 Pa, and detect the air leakage rat...

Embodiment 2

[0072] This application provides a high-quality, high-density, high-tungsten, high-cobalt-nickel alloy, the chemical composition of which is 35% tungsten, 22% cobalt and 43% nickel by mass percentage;

[0073] Prepare materials according to the above alloy composition, melt and pour the alloy raw materials into electrode ingots with a diameter of 250 mm in a vacuum induction furnace;

[0074] Cut off the head and tail of the electrode ingot, and polish the surface to reveal the metallic luster; weld the auxiliary electrode and bake it in a heating furnace at 220°C for 3.5 hours to remove water vapor; wipe the surface of the electrode with a clean rag to clean oil and oxidation after leaving the furnace and air cooling Foreign objects such as objects;

[0075] Put the processed electrode in the vacuum consumable furnace, complete the furnace loading, centering, sealing and other operations, feed the cooling water flow rate of 750 mL / min, vacuumize to 0.20 Pa, and detect the air...

Embodiment 3

[0084] This application provides a high-quality, large-density, high-tungsten, high-cobalt-nickel alloy, the chemical composition of which is 42% tungsten, 16% cobalt and 42% nickel by mass percentage;

[0085] Prepare materials according to the above alloy composition, melt and pour the alloy raw materials into electrode ingots with a diameter of 220 mm in a vacuum induction furnace;

[0086] Cut the head and tail of the electrode ingot, and polish the surface to reveal the metallic luster; weld the auxiliary electrode and bake it in a heating furnace at 280°C for 3 hours to remove water vapor; wipe the surface of the electrode with a clean rag to clean oil and oxidation after leaving the furnace and air cooling Foreign objects such as objects;

[0087] Put the treated electrode in the vacuum consumable furnace, complete the furnace loading, centering, sealing and other operations, feed the cooling water flow rate of 600 mL / min, vacuumize to 0.10 Pa, and detect the air leakag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com