Engine emission test low-temperature tail gas treatment system and treatment process

An engine, low-temperature flue gas technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of high construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

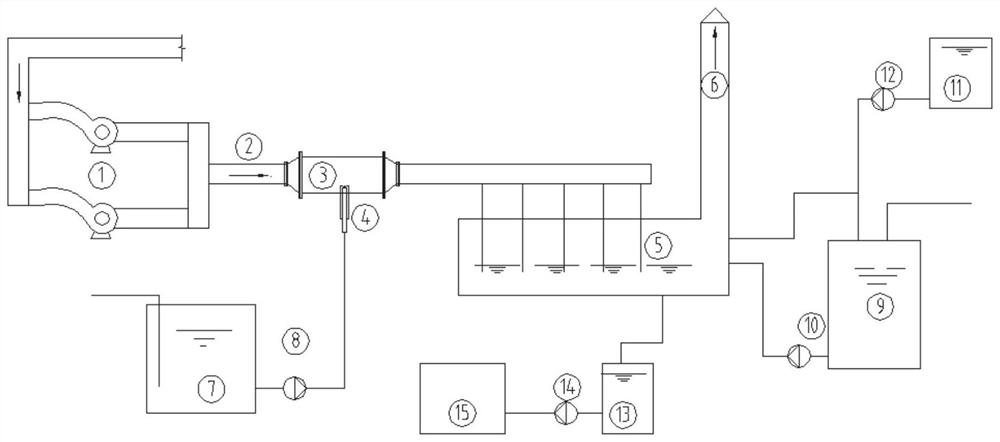

[0046] Such as figure 1 As shown, a low-temperature tail gas treatment system for engine emission test includes: a denitrification reactor 3, which is communicated with the exhaust gas source of the engine emission test through a smoke exhaust fan 1, and a spray gun 4 is arranged in the denitrification reactor 3, and the inlet of the spray gun 4 is connected to the chlorinated Sodium acid solution storage tank 7 is communicated;

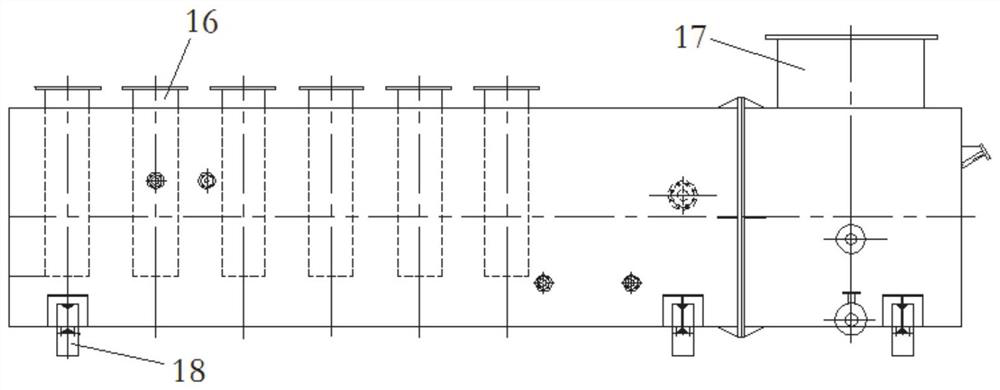

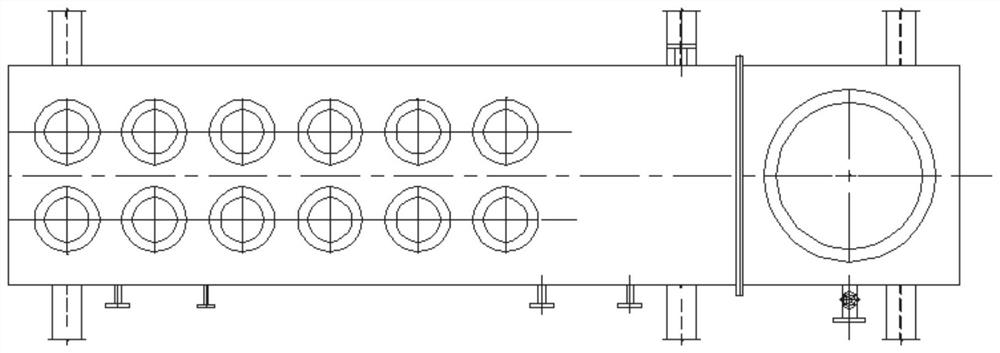

[0047] Such as figure 2 , image 3 and Figure 4 As shown, the scrubber 5 provides an integrated reaction space, the scrubber 5 is a horizontal structure, and the top of one end of the scrubber 5 is provided with a chimney 6; the inner diameter of the scrubber 5 is 1500 mm, and the end of the scrubber 5 is provided with a chimney. Install the base, the diameter of the chimney installation base is 1000mm, and the height is 500mm. The overall length of the scrubber is 6500mm. The bottom of the scrubber 5 is provided with a bearing 18, and the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com