Covalent organic framework doped liquid chromatography monolithic column and preparation method thereof

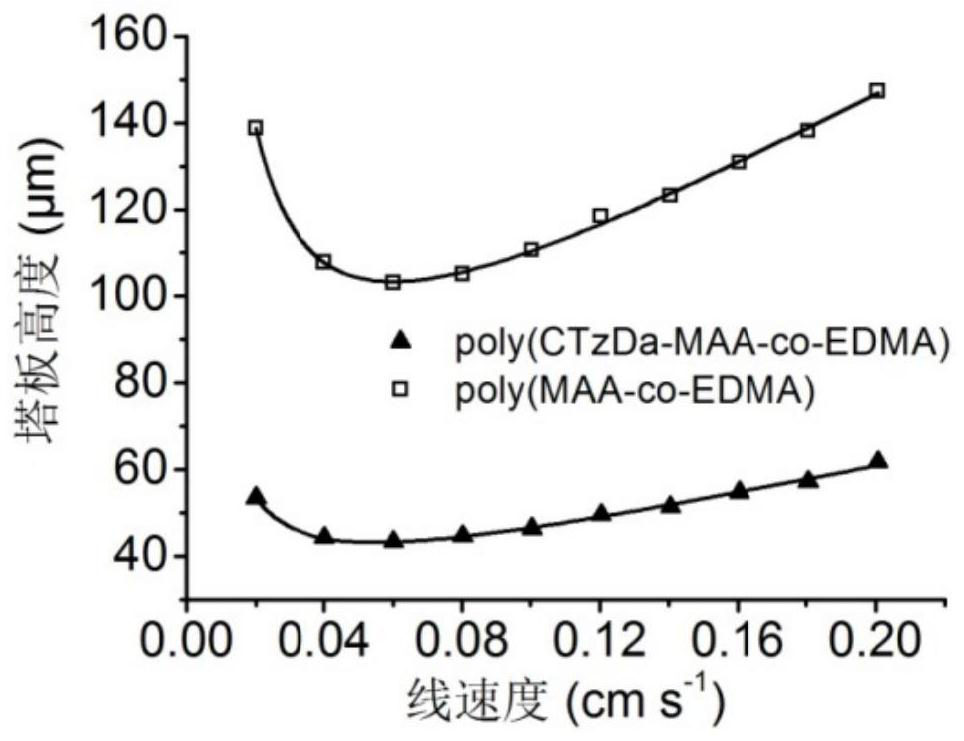

A technology of covalent organic framework and doped liquid phase, applied in the field of chromatographic separation, can solve problems such as the need to improve the selectivity of the monolithic column, and achieve the effects of solving high column pressure, simple operation, and improving permeability and column efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

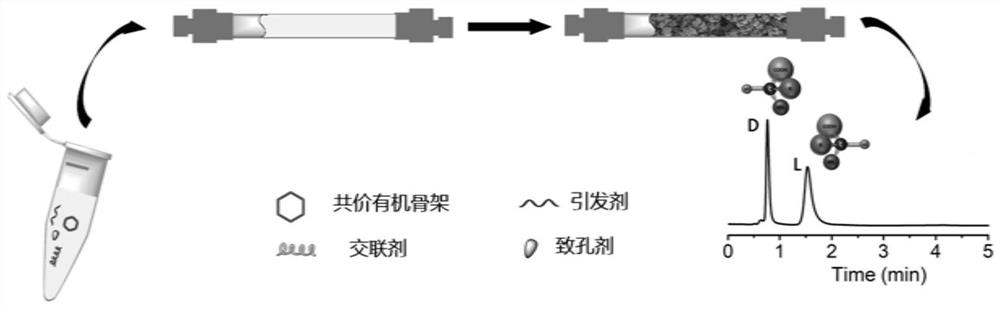

[0037] Example 1: Preparation of Chiral Covalent Organic Framework Doped Liquid Chromatography Monolithic Column

[0038] (1) Preparation of chiral covalent organic framework CTzDa: take 31mg (0.09mmol) 2,4,6-tris(4-aminophenyl)-1,3,5-triazine (Tz) and 21.6mg (0.13 mmol) 1,4-dihydroxyterephthalaldehyde (Da), placed in 1mL dichlorobenzene and 1mL ethanol mixed solution, then add 0.2mL 6mol L -1 Acetic acid solution, after ultrasonication for 10min, left to react at room temperature for 3d, centrifuged and dried, mixed and dispersed the obtained powder with 1.3mmol D-camphoryl chloride in 40mL of anhydrous tetrahydrofuran, added 400μL of triethylamine, and reacted at room temperature for 12h. After the reaction, the product was washed with water and tetrahydrofuran respectively, replaced with dichloromethane for one day, and dried in a vacuum oven at 50°C for 12 hours to obtain the chiral covalent organic framework CTzDa;

[0039] (2) Disperse 15 mg of chiral covalent organic f...

Embodiment 2

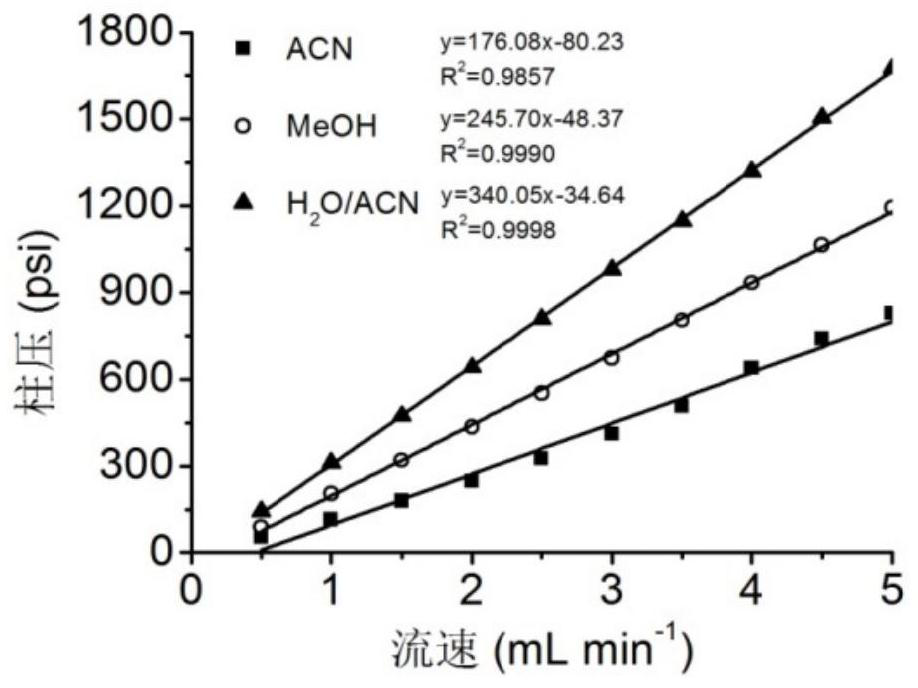

[0046] A method for preparing a covalent organic framework doped liquid chromatography monolithic column, the steps and method are basically the same as in Example 1, the difference is that the covalent organic framework used is enol TpBD, and other conditions remain unchanged, and the obtained The covalent organic framework characterization results are similar to Example 1. The obtained covalent organic framework has good mechanical strength and low column pressure (not more than 1800 psi).

Embodiment 3

[0048] A method for preparing a covalent organic framework-doped liquid chromatography monolithic column, the steps and method are basically the same as in Example 1, the difference is that the solvent used is ethanol, and other conditions remain unchanged, and the prepared covalent organic framework is characterized The result is similar to Example 1. The obtained covalent organic framework has good mechanical strength and low column pressure (not more than 1800 psi).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com