A fast-setting adjustable cement-based underwater anti-dispersion ultra-fast hard grouting material, preparation method and application

A grouting material and cement-based technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of cleaning grouting equipment, such as difficulty in cleaning grouting equipment, dispersing, and time occupation of skylights, and achieves easy control of construction and application, simple preparation methods, Good effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

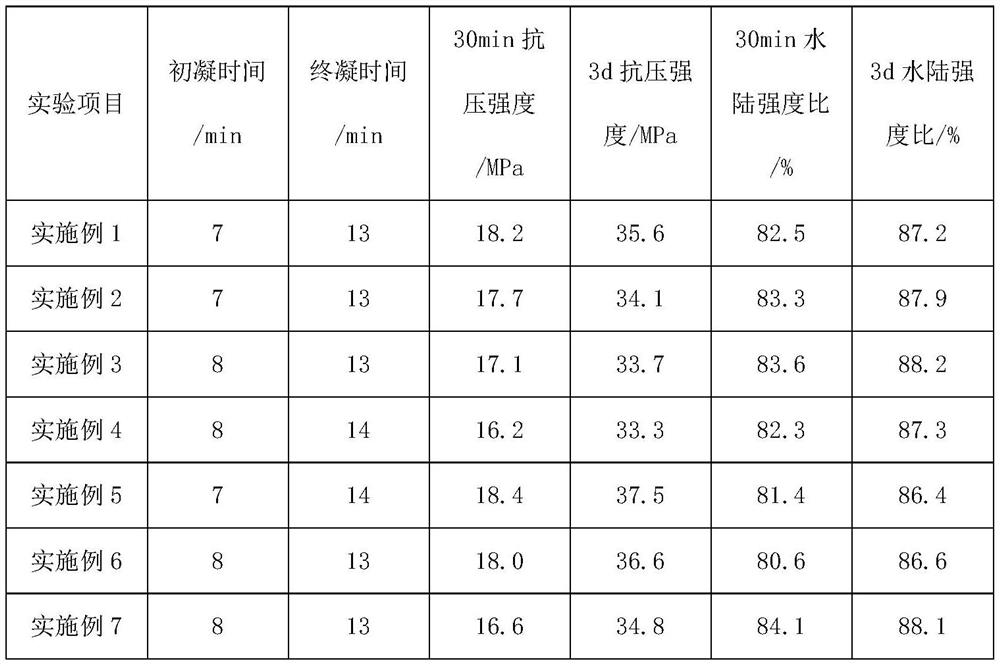

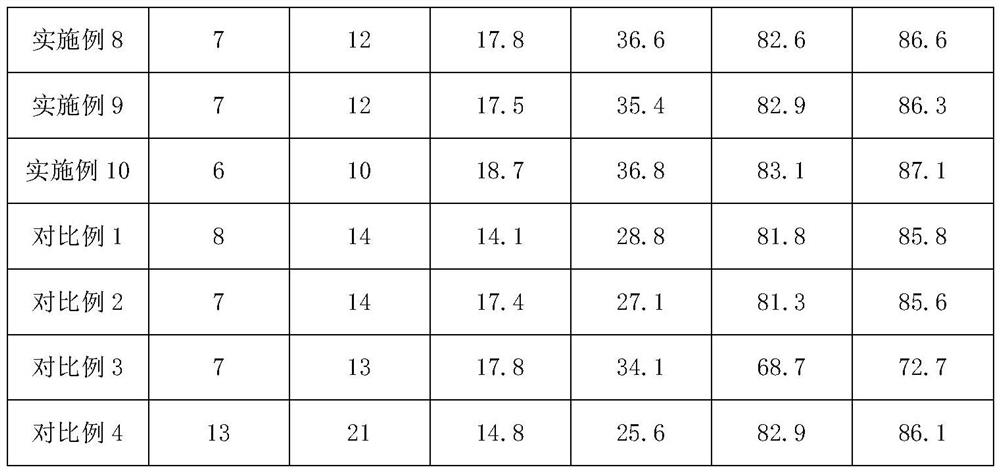

Examples

Embodiment 1

[0052] The present invention will be further described below in conjunction with examples, but the content of the present invention is not limited to the following examples.

[0053] Example 1

[0054] A fast-setting adjustable cement-based underwater anti-dispersion ultra-fast hard grouting material, which is composed of A component and B component, in terms of mass percentage, A component formula: 80% of cementitious material, active admixture 10%, expansion agent 7%, high-performance underwater anti-dispersion agent 2.7%, polycarboxylate high-performance water reducer 0.3%; B component formula: rapid hardening gelling material 80%, active admixture 9.5%, expansion 7%, high-performance underwater anti-dispersion agent 2.7%, polycarboxylate high-performance water reducer 0.3%, sodium gluconate 0.2%, lithium carbonate 0.1%, magnesium aluminum silicate 0.1%, isobutyl triethoxy Silane 0.1%. The cementitious material is ordinary Portland cement with a strength grade of 52.5; th...

Embodiment 2

[0066] A fast-setting and adjustable cement-based underwater anti-dispersion ultra-fast hard grouting material, which is composed of A component and B component. According to the mass percentage, the A component formula: 85% of cementitious material, active admixture 7%, expansion agent 5%, high-performance underwater anti-dispersion agent 2.8%, polycarboxylate high-performance water reducer 0.2%; B component formula: rapid hardening gelling material 85%, active admixture 6.5%, expansion 5%, high-performance underwater anti-dispersion agent 2.8%, polycarboxylate high-performance water reducer 0.2%, sodium gluconate 0.2%, lithium chloride 0.1%, polyamide wax 0.1%, isobutyl triethoxy Silane 0.1%. The cementitious material is ordinary Portland cement with a strength grade of 52.5; the rapid-hardening cementitious material is a rapid-hardening sulfoaluminate cement with a strength grade of 42.5; the active admixture has a specific surface area≧900m 2 / kg, 28d activity index ≧ 90%...

Embodiment 3

[0072] A fast-setting adjustable cement-based underwater anti-dispersion ultra-fast hard grouting material, which is composed of A component and B component, in terms of mass percentage, A component formula: 90% of cementitious material, active admixture 4%, expansion agent 3%, high-performance underwater anti-dispersion agent 2.9%, polycarboxylate high-performance water reducer 0.1%; B component formula: rapid hardening gelling material 90%, active admixture 3.5%, expansion 3%, high-performance underwater anti-dispersion agent 2.9%, polycarboxylate high-performance water-reducing agent 0.1%, sodium gluconate 0.2%, lithium carbonate 0.1%, magnesium aluminum silicate 0.1%, vinyl triethoxysilane 0.1%. The cementitious material is ordinary Portland cement with a strength grade of 52.5; the rapid-hardening cementitious material is a rapid-hardening sulfoaluminate cement with a strength grade of 52.5; the active admixture has a specific surface area≧900m 2 / kg, 28d activity index ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com