Preparation method and application of vegetable oil-based environmentally friendly plasticizer with high thermal stability

An environmentally friendly plasticizer and high thermal stability technology, applied in the preparation of organic compounds, carboxylate esters, chemical instruments and methods, etc., to achieve outstanding mechanical properties, facilitate industrial processing, and light color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

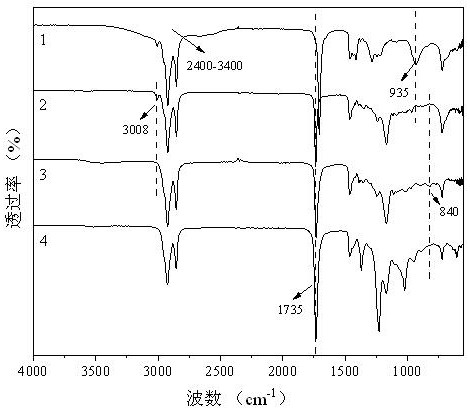

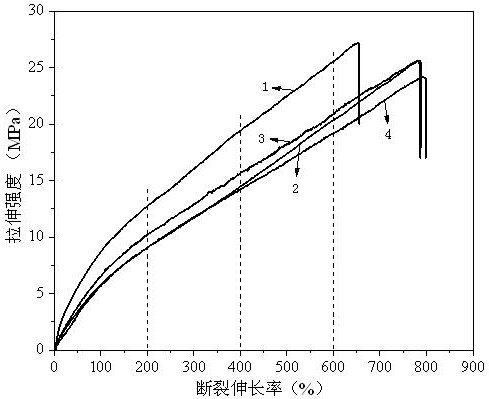

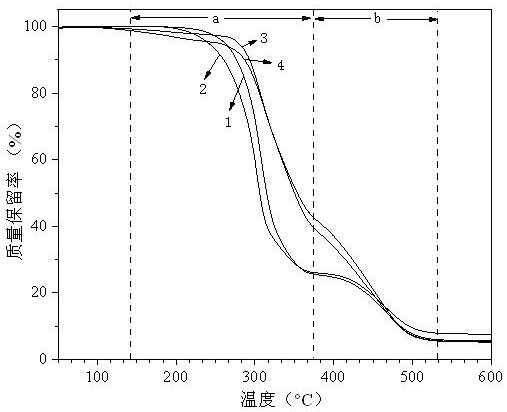

[0026] (1) Esterification reaction: Add oleic acid and 1,8-octanediol to the reactor, wherein the molar ratio of 1,8-octanediol:oleic acid is 1:1, and nitrogen gas is introduced for 5 minutes, and the reaction is heated to 110°C; then add the catalyst tetra-n-butyl titanate, and then raise the temperature to 180°C for 2 hours; after the reaction, add 15% sodium hydroxide solution, heat to 80°C, and react for 0.1h; after the reaction Carry out centrifugation, take the supernatant and wash it with deionized water to neutrality, and then vacuum distill at -0.1MPa at 60°C for 0.5h to remove the residual water to obtain the product 1,8-octanediol dioleate;

[0027] (2) Epoxidation reaction: Add the 1,8-octanediol dioleate prepared in step (1) and the catalyst strong-acid cation exchange resin into the reactor, mix formic acid and hydrogen peroxide, and then Add the mixture dropwise into the reactor, heat and react at 30°C for 8 hours; the mass fraction of hydrogen peroxide solution...

Embodiment 2

[0030] (1) Esterification reaction: Add oleic acid and 1,8-octanediol to the reactor, wherein the molar ratio of 1,8-octanediol:oleic acid is 1:2, blow nitrogen for 25 minutes, and heat the reaction to 140°C; then add the catalyst tetra-n-butyl titanate, and then increase the temperature to 150°C for 7 hours; after the reaction, add a 20% sodium hydroxide solution, heat to 60°C, and react for 1 hour; Centrifuge, take the supernatant and wash it with deionized water to neutrality, then vacuum distill at -0.1MPa at 70°C for 1 hour to remove residual water to obtain the product 1,8-octanediol dioleate;

[0031](2) Epoxidation reaction: Add the 1,8-octanediol dioleate prepared in step (1) and catalyst 2 strong acid type cation exchange resin into the reactor, mix formic acid and hydrogen peroxide, and then Add the mixture dropwise to the reactor, heat and react at 80°C for 3 hours; the mass fraction of hydrogen peroxide solution is 40%, and the molar ratio of 1,8-octanediol diolea...

Embodiment 3

[0034] (1) Esterification reaction: Add oleic acid and 1,8-octanediol into the reactor, wherein the molar ratio of 1,8-octanediol:oleic acid is 1: 3, blow nitrogen for 40 minutes, and heat the reaction to 160°C; then add the catalyst tetra-n-butyl titanate, and then raise the temperature to 120°C for 9 hours; after the reaction, add a 25% sodium hydroxide solution, heat to 20°C, and react for 2 hours; Centrifuge, take the supernatant and wash it with deionized water to neutrality, then vacuum distill at -0.1MPa at 80°C for 2 hours to remove the residual water to obtain the product 1,8-octanediol dioleate;

[0035] (2) Epoxidation reaction: Add the 1,8-octanediol dioleate prepared in step (1) and catalyst 2 strong acid type cation exchange resin into the reactor, mix formic acid and hydrogen peroxide, and then Add the mixture dropwise into the reactor, and heat the reaction at 50°C for 6 hours; the mass fraction of hydrogen peroxide solution is 50%, and the molar ratio of 1,8-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com