Thermal activation delayed fluorescence material capable of being processed by solution, preparation method and application thereof

A technology of thermally activated delayed and fluorescent materials, applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc. Properties, preparation and purification methods are simple, and the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

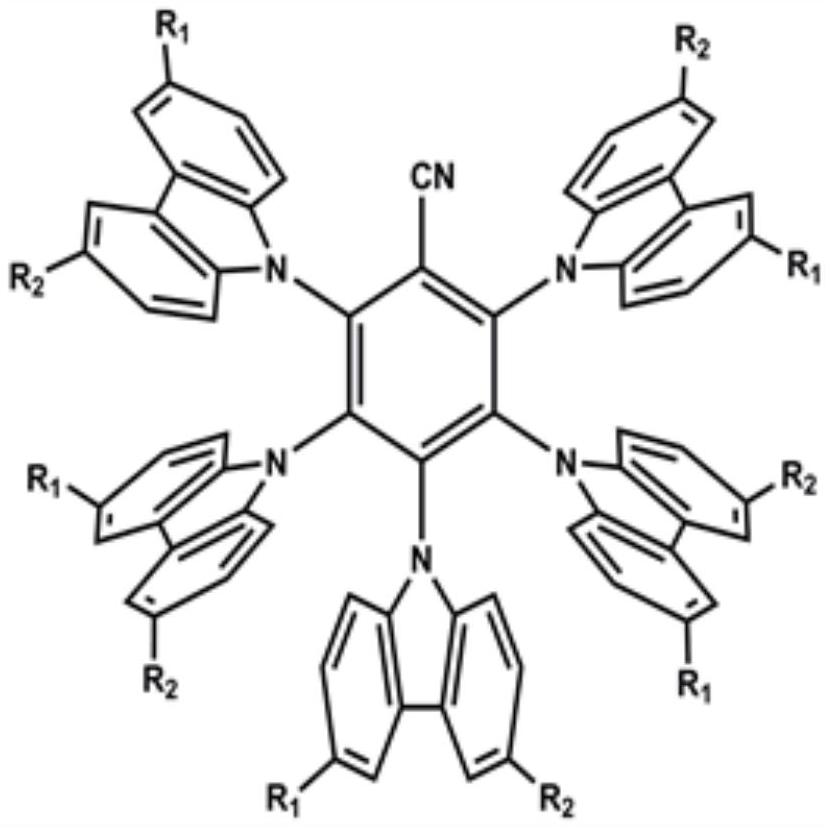

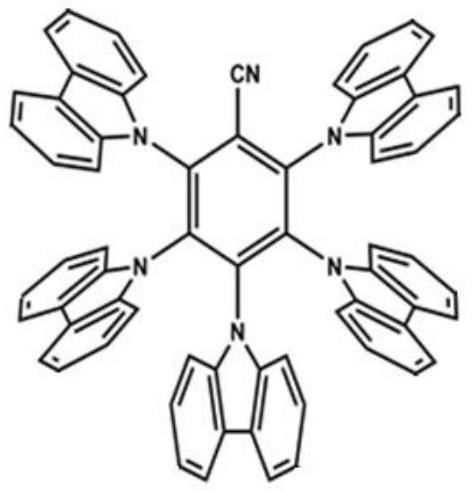

[0032] Embodiment 1: the synthesis of compound C1

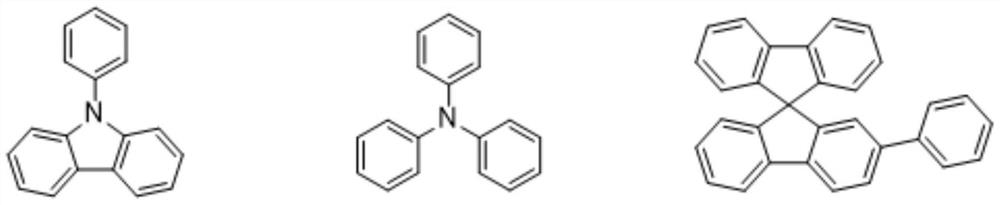

[0033] Step 1, Synthesis of 3,6-bis(4-(9H-carbazol-9-yl)phenoxy)-9H-carbazole in peripheral dendrons

[0034] Add 3,6-dihydroxy-9-hydrogen-carbazole (10g, 25.12mmol), cesium carbonate (4.5g, 13.84mmol), 9-(4-iodophenyl)-9H-carbazole into a 500mL reaction flask (15g, 54.94mmol), N,N-dimethylformamide (200mL), under the protection of nitrogen, react at 100°C for 4h. After the reaction was finished, cool to room temperature, add a large amount of water to stir, and filter with suction to obtain the crude product. Then, it was purified by column chromatography to obtain 3,6-bis(4-(9H-carbazol-9-yl)phenoxy)-9H-carbazole as a white solid with a yield of 70%.

[0035] Step 2, Synthesis of C1

[0036] In dry tetrahydrofuran (THF, 20 mL) was added 3,6-bis(4-(9H-carbazol-9-yl)phenoxy)-9H-carbazole (3.26 g, 3.15 mmol), sodium hydride (0.5 g, 20.3mmol), stirred at room temperature for 0.5h, then added 2,3,4,5,6-pentafluorobenzonitril...

Embodiment 2

[0041] Embodiment 2: Synthesis of C2

[0042] The 3,6-dihydroxy-9-hydrogen-carbazole that reacts with 9-(4-iodophenyl)-9H-carbazole in Example 1 is replaced with 3-hydroxyl carbazole, and through the same process as in Example 1 Synthetic method, the product C2 was obtained. Yield 70%.

[0043] Mass Spectrum: 2214.76.

[0044] Elemental analysis results: C: 85.11, H: 4.32, N: 6.95, O: 3.61.

Embodiment 3

[0045] Embodiment 3: Synthesis of C3

[0046]In the above example 1, the 9-(4-iodophenyl)-9H-carbazole reacted with 3,6-dihydroxy-9-hydrogen-carbazole was replaced by 4-iodo-N, N-diphenylaniline , through the same synthesis method as in Example 1, the product C3 was obtained. Yield 71%.

[0047] Mass spectrum: 3520.33.

[0048] Elemental analysis results: C: 84.23, H: 4.87, N: 6.36, O: 4.56.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com