Anti-adhesion gel and preparation method thereof

An anti-adhesion and gel technology, used in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve the problems of decreased bonding force and shortened service life of cookware, so as to improve impact resistance and prolong service life. , good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

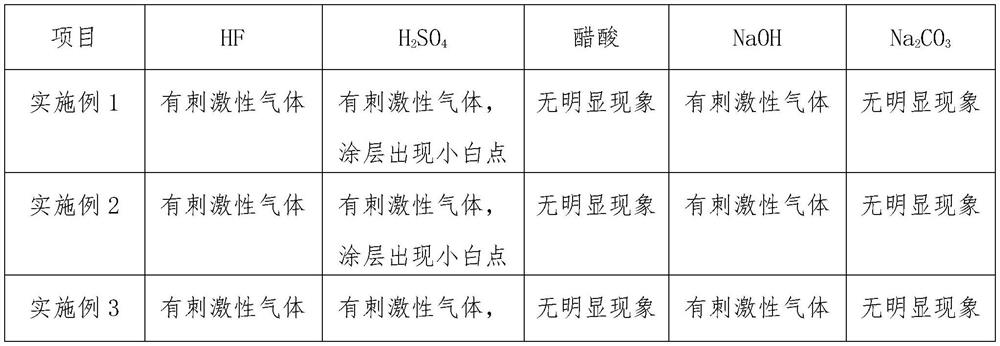

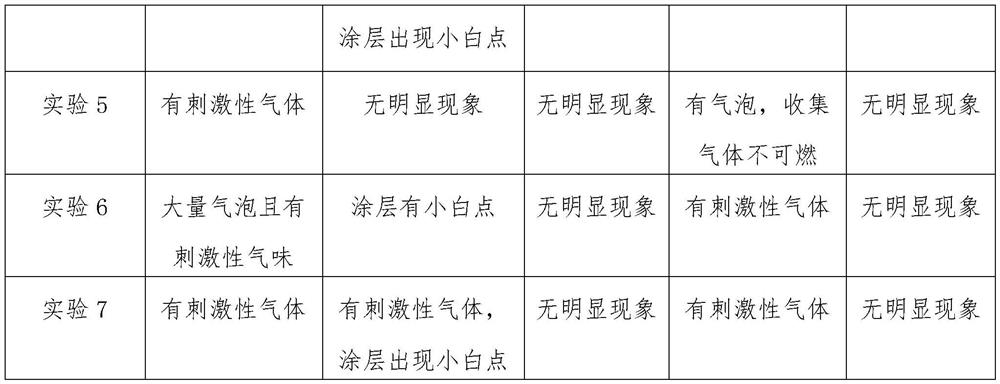

Examples

Embodiment 1

[0025] An anti-adhesion gel, its composition includes by weight: 15 parts of modified silicon carbide, 20 parts of hydrotalcite, 17 parts of hydrogenated camellia oil, 10 parts of polyvinyl alcohol, 6 parts of succinic acid solution, 5-methyl- 2 parts of 2-isopropylphenol.

[0026] The specific steps are:

[0027] 1. Preparation of hydrogenated camellia oil:

[0028] a. The camellia seeds are screened and cleaned by magnetic separation and adsorption, then shelled, dried on the surface and then frozen, and the frozen camellia seeds are pressed in a screw oil press at 57°C, and the oil residue is quickly separated and left to settle 2h filtered to obtain crude oil;

[0029] b. Degumming treatment: heating the crude oil to 60°C, adding phosphoric acid solution with 9% crude oil volume and 5% crude oil mass phospholipase, stirring for 15 minutes and centrifuging to obtain degummed camellia oil;

[0030] c. Dehydration treatment: add 4% of its weight anhydrous sodium carbonate ...

Embodiment 2

[0039] An anti-adhesion gel, its composition includes by weight: 21 parts of modified silicon carbide, 25 parts of hydrotalcite, 23 parts of hydrogenated camellia oil, 13 parts of polyvinyl alcohol, 8 parts of succinic acid solution, 5-methyl- 3 parts of 2-isopropylphenol.

[0040] The specific steps are:

[0041] 1. Preparation of hydrogenated camellia oil:

[0042] a. The camellia seeds are screened and cleaned by magnetic separation and adsorption, then shelled, dried on the surface and then frozen, and the frozen camellia seeds are pressed in a screw oil press at 65°C, and the oil residue is quickly separated and left to settle 2h filtered to obtain crude oil;

[0043] b. Degumming treatment: heating the crude oil to 70°C, adding phosphoric acid solution with 11% crude oil volume and 6% crude oil mass phospholipase, stirring for 20min and centrifuging to obtain degummed camellia oil;

[0044] c. Dehydration treatment: add 5% of its weight anhydrous sodium carbonate to t...

Embodiment 3

[0053] An anti-adhesion gel, its composition includes by weight: 10 parts of modified silicon carbide, 14 parts of hydrotalcite, 11 parts of hydrogenated camellia oil, 7 parts of polyvinyl alcohol, 4 parts of succinic acid solution, 5-methyl- 2 parts of 2-isopropylphenol.

[0054] The specific steps are:

[0055] 1. Preparation of hydrogenated camellia oil:

[0056] a. The camellia seeds are screened and cleaned by magnetic separation and adsorption, then shelled, dried on the surface and then frozen, and the frozen camellia seeds are squeezed in a screw oil press at 50°C, and the oil residue is quickly separated and left to settle 2h filtered to obtain crude oil;

[0057] b. Degumming treatment: heating the crude oil to 50°C, adding phosphoric acid solution with 7% crude oil volume and phospholipase with 4% crude oil mass, stirring for 10 minutes and centrifuging to obtain degummed camellia oil;

[0058] c. Dehydration treatment: add 3% of its weight anhydrous sodium carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com