System and method for removing sulfur dioxide from liquid-phase hydrocarbons

A technology for sulfur dioxide and hydrocarbons, which is applied in the field of petrochemical industry, can solve the problems that cannot be reached, does not involve sulfur dioxide removal devices and adsorbent regeneration devices, and achieves the effects of long regeneration period, simple and practical operation, and high removal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

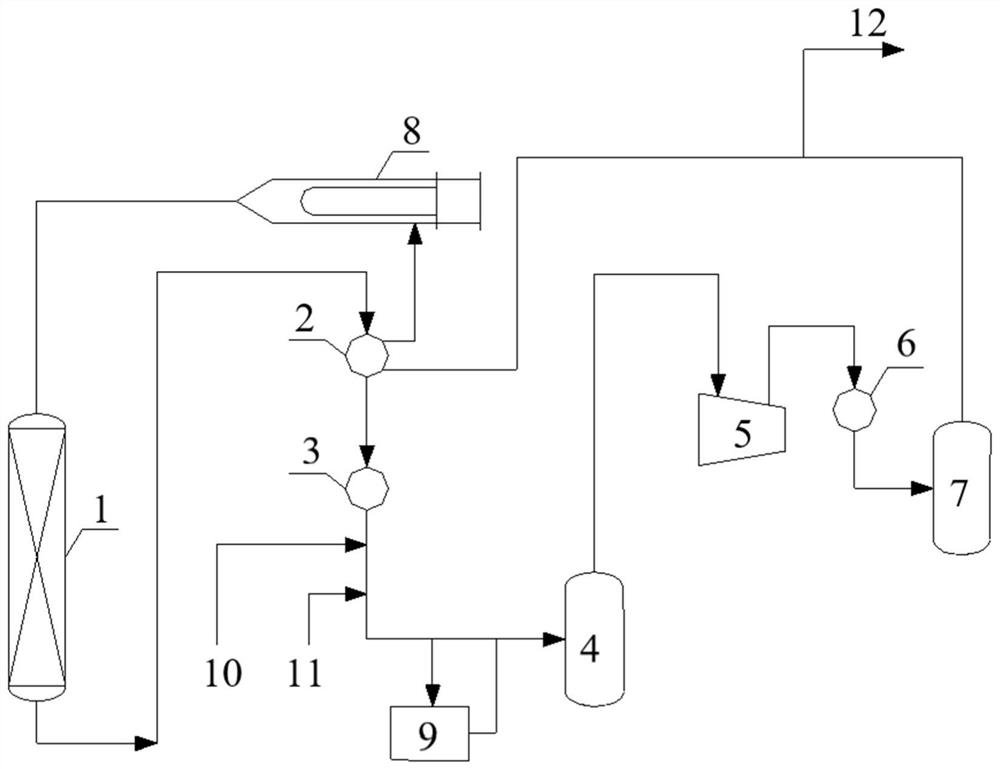

[0077] A certain device has a liquid-phase C4 feed, and the specific composition is shown in Table 1 below. The stock material contains sulfur dioxide, and the concentration of sulfur dioxide is 30-300ppm. After research, sulfur dioxide will affect the activity and selectivity of the dehydrogenation catalyst, and the device requires the content of sulfur dioxide in the feed to be ≤ 1ppm.

[0078] Table 1 Liquid phase hydrocarbon feed composition table

[0079] composition Content (wt%) propane 4.84 n-butane 9.54 Isobutane 85.1 Isopentane 0.51 heavy component 0.002 water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com