Perovskite solar cell without electron transport layer and hole transport layer and manufacturing method

A technology of hole-transport layer and electron-transport layer, which is applied in the field of perovskite solar cells without electron-transport layer and hole-transport layer and its production, can solve the problems of exacerbating device degradation, achieve dark current density reduction, and achieve good photoelectric conversion effect, the effect of improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

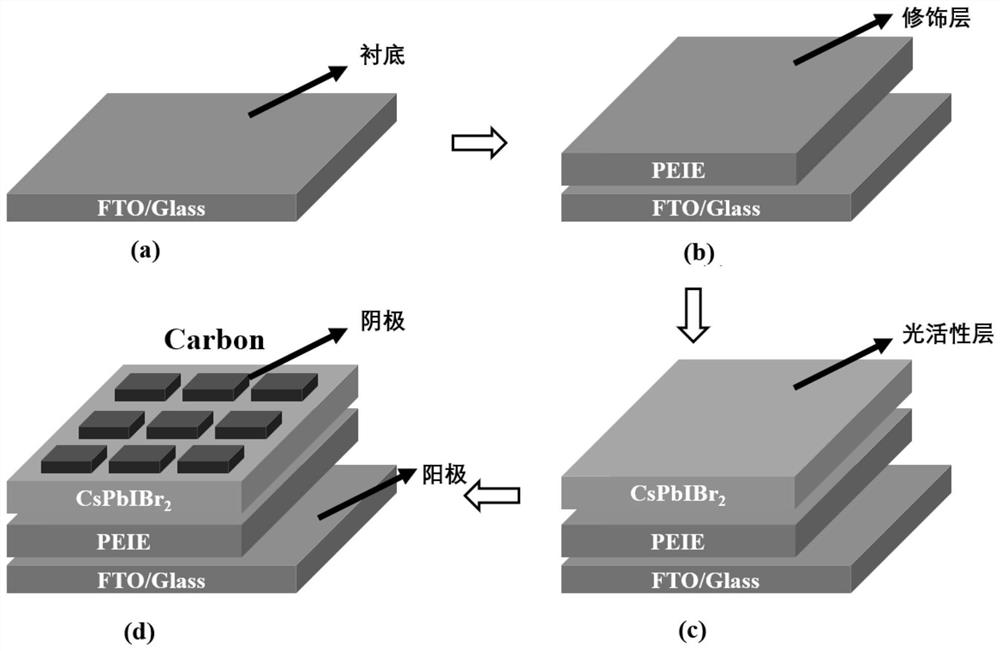

[0039] (1) Clean the FTO substrate: Put the FTO substrate into Decon-90 aqueous solution, deionized water, acetone, alcohol and deionized water for 15 minutes for ultrasonic cleaning;

[0040] (2) UV-O 3 Treatment of FTO substrate: place the cleaned FTO substrate in UV-zone for 30min. like figure 1 as shown in (a);

[0041] (3) Preparation of PEIE modification layer: PEIE deionized aqueous solution was directly spin-coated on the FTO substrate at a speed of 3000 rpm in the air environment, and placed on a hot stage at a constant temperature of 250° C. in the air environment for annealing for 20 min. PEIE deionized water solution is prepared by dissolving a certain amount of PEIE solution in deionized water. Wherein the concentration of PEIE solution is 4mg / mL such as figure 1 as shown in (b);

[0042] (4) Preparation of CsPbIBr 2 Thin film: take PbBr with a mass ratio of 330mg 2 Solid, 27.8 mg of PbCl 2 Solid and 260.0mg CsI solid, dissolved in 1mL of dimethyl sulfoxid...

Embodiment 2

[0045] 1) Clean the FTO substrate: Put the FTO substrate into Decon-90 aqueous solution, deionized water, acetone, alcohol and deionized water for 20 minutes for ultrasonic cleaning;

[0046] 2) UV-O 3 Treatment of FTO substrates: place the cleaned FTO substrates in a UV-zone for 35 minutes.

[0047] like figure 1 as shown in (a);

[0048] 3) Preparation of PEIE modification layer: PEIE deionized aqueous solution was directly spin-coated on the FTO substrate at a speed of 3000 rpm in the air environment, and placed on a hot stage at a constant temperature of 250° C. in the air environment for annealing for 20 minutes. PEIE deionized water solution is prepared by dissolving a certain amount of PEIE solution in deionized water. Wherein the concentration of PEIE solution is 8mg / mL such as figure 1 as shown in (b);

[0049] 4) Preparation of CsPbIBr 2 Film: take 330mg of PbBr 2 Solid, 27.8 mg of PbCl 2 Solid and 260.0mg CsI solid, dissolved in 1mL of dimethyl sulfoxide sol...

Embodiment 3

[0052] 1) Clean the FTO substrate: put the FTO substrate into Decon-90 aqueous solution, deionized water, acetone, alcohol, and deionized water for 15 minutes for ultrasonic cleaning;

[0053] 2) UV-O 3 Treat the FTO substrate: place the cleaned FTO substrate in the UV-zone for 40 minutes.

[0054] like figure 1 as shown in (a);

[0055] 3) Preparation of PEIE modification layer: PEIE deionized aqueous solution was directly spin-coated on the FTO substrate at a speed of 3000 rpm in the air environment, and placed on a hot stage at a constant temperature of 250° C. in the air environment for annealing for 20 minutes. PEIE deionized water solution is prepared by dissolving a certain amount of PEIE solution in deionized water. Wherein the concentration of PEIE solution is 12mg / mL such as figure 1 as shown in (b);

[0056] 4) Preparation of CsPbIBr 2 Thin film: take PbBr with a mass ratio of 330mg 2 Solid, 27.8 mg of PbCl 2 Solid and 260.0mg of CsI solid, dissolved in 1mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com