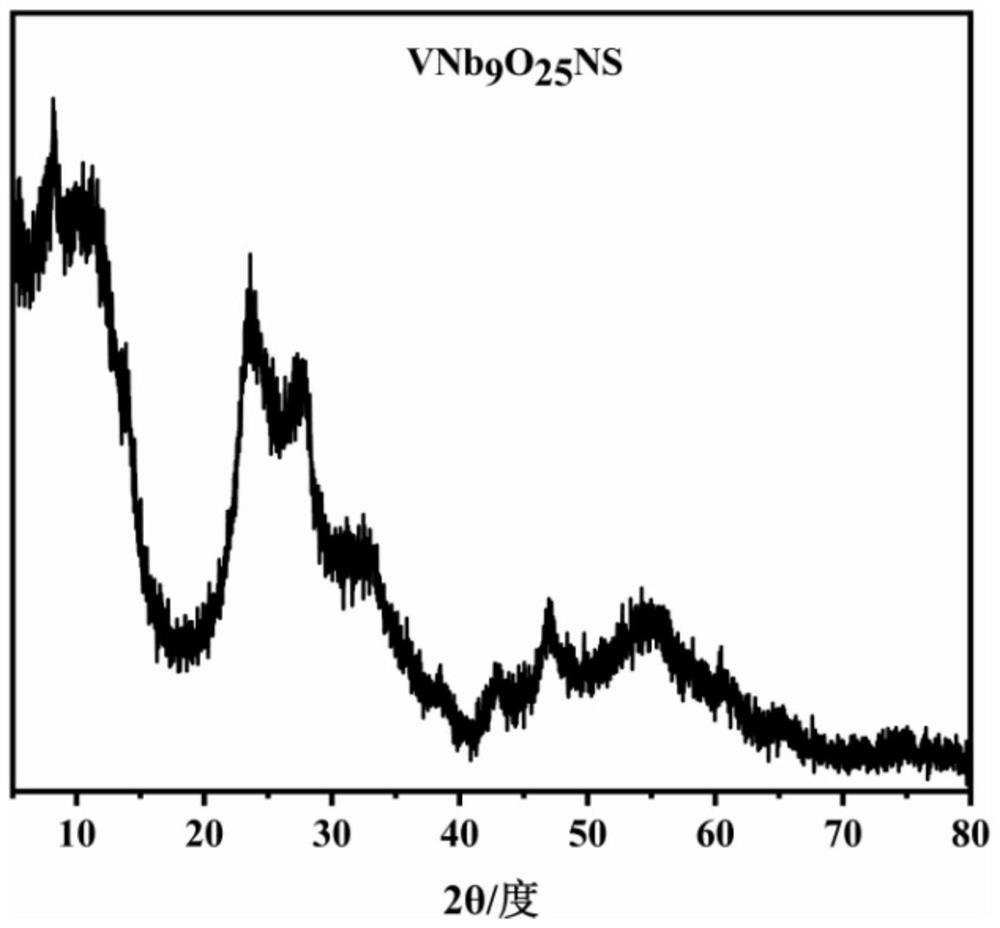

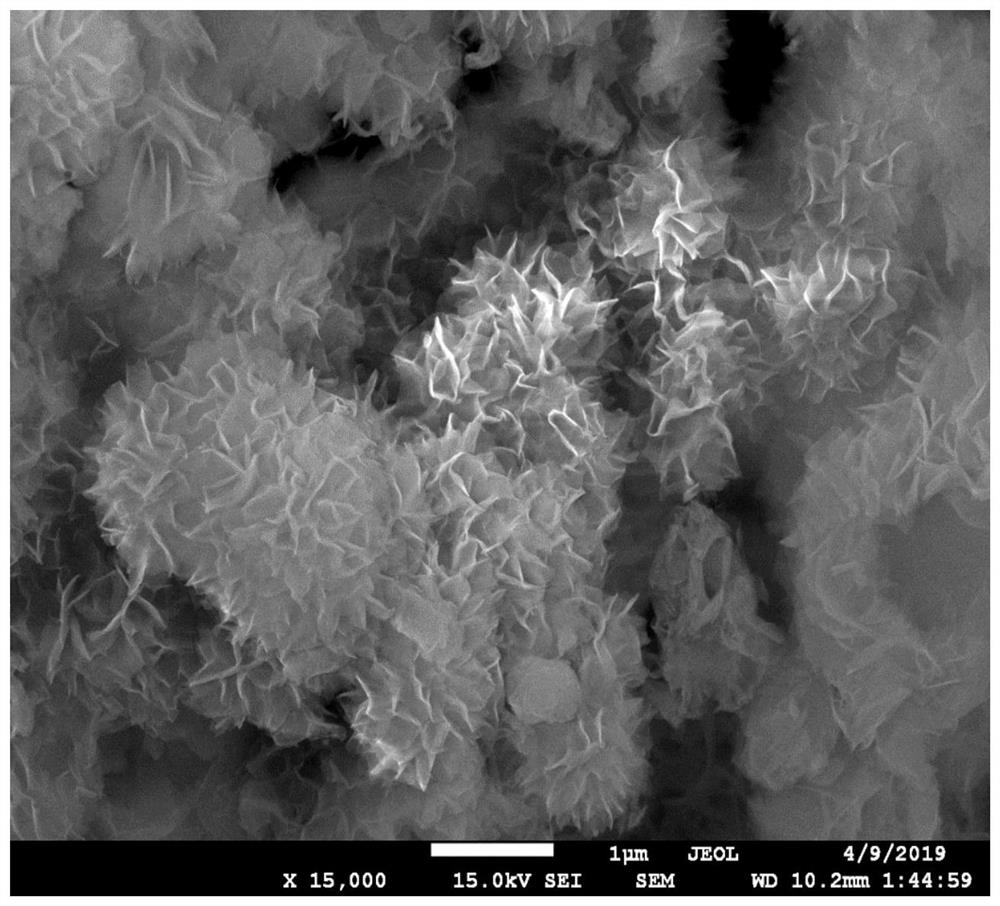

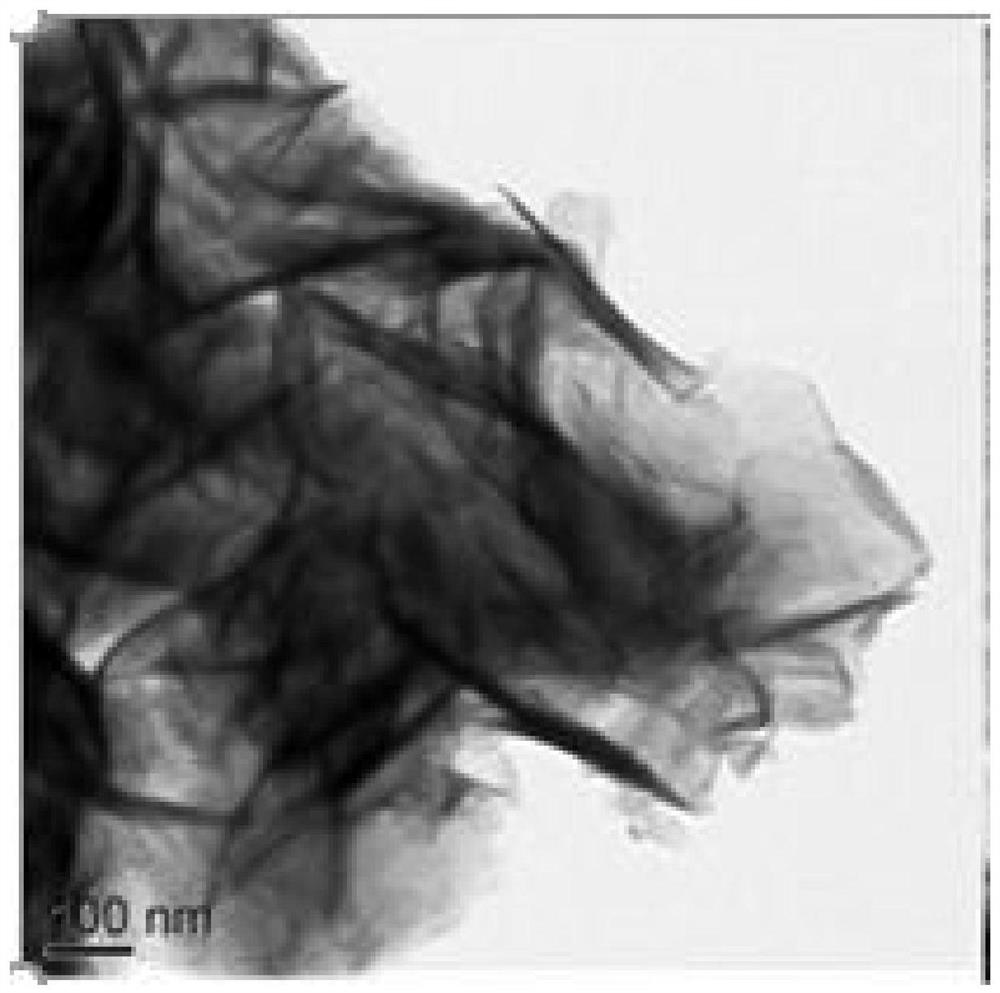

High-capacity VNb9O25 nanosheet lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, nanotechnology and other directions, can solve the problems of limited practical use, poor electrical conductivity and capacity retention, and achieve low cost, good cycle performance, shape and size. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The high-capacity VNb of this embodiment 9 o 25 The preparation method of nanosheet lithium ion battery negative electrode material is as follows:

[0038] (1) Dissolve 2.7 mmoles of niobium pentachloride (0.73 g) in 36 ml of absolute ethanol and stir for 0.5-1 hour to dissolve completely;

[0039] (2) Add 0.3 mmol of vanadyl acetylacetonate powder to the solution as a vanadium source, at this time, V:Nb is 1:9, and then ultrasonically shake for 0.5-1 hour to completely dissolve it;

[0040] (3) Add 20 mL of 25% tetramethylammonium hydroxide aqueous solution dropwise at a rate of 0.6 mL / min to the mixed solution for reaction, and stir until a clear solution is formed. At this time (vanadyl acetylacetonate+penta The molar ratio of niobium chloride) to tetramethylammonium hydroxide is 1:25.6;

[0041] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature drying...

Embodiment 2

[0047] (1) Dissolve 2.7 mmoles of niobium pentachloride (0.73 g) in 36 ml of absolute ethanol and stir for 0.5-1 hour to dissolve completely;

[0048] (2) Add 0.3 mmol of vanadyl acetylacetonate powder to the solution as a vanadium source, at this time, V:Nb is 1:9, and then ultrasonically shake for 0.5-1 hour to completely dissolve it;

[0049] (3) Add 30 mL of tetramethylammonium hydroxide aqueous solution dropwise to the mixed solution at a rate of 0.6 mL / min, and stir to dissolve it completely. At this time (vanadyl acetylacetonate + niobium pentachloride) and The mol ratio of methyl ammonium hydroxide is 1:38.3;

[0050] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature drying oven for heating reaction. The temperature of the heating reaction was 240°C, and the reaction time was 12 hours;

[0051] (5) The obtained reaction precipitate was washed several times...

Embodiment 3

[0056] The high-capacity VNb of this embodiment 9 o 25 The preparation method of nanosheet lithium ion battery negative electrode material is as follows:

[0057] (1) Dissolve 3 mmoles of niobium pentachloride (0.81g) in 36 ml of absolute ethanol and stir for 0.5-1 hour to dissolve completely;

[0058] (2) Add 0.6 mmol of vanadyl acetylacetonate powder to the solution as a vanadium source, at this time, V:Nb is 1:5, and then ultrasonically shake for 0.5-1 hour to completely dissolve it;

[0059] (3) Add 35 mL of tetramethylammonium hydroxide aqueous solution with a mass fraction of 25% dropwise into the mixed solution at a rate of 0.6 mL / min, and stir to dissolve it completely. At this time (vanadyl acetylacetonate + The molar ratio of niobium chloride) to tetramethylammonium hydroxide is 1:37.3;

[0060] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com