Method for preparing geopolymer by coupling FCC waste catalyst and red mud

A geopolymer and waste catalyst technology, applied in the field of solid waste resource utilization, can solve problems such as occupation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

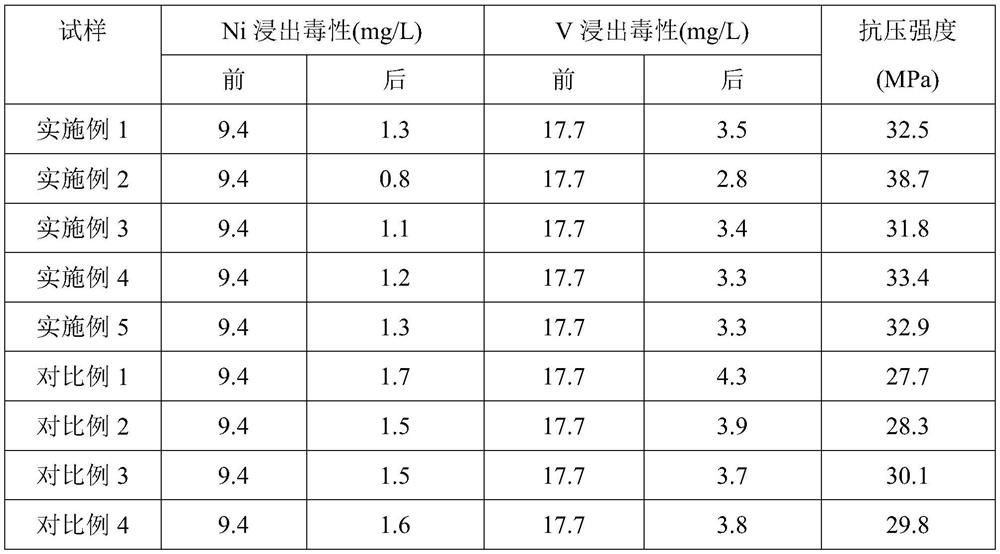

Examples

Embodiment 1

[0044] A geopolymer prepared by coupling FCC waste catalyst with sintering red mud, wherein the main components in the sintering red mud are: SiO 2 The content is about 21.06wt%, Al 2 o 3 The content of CaO is about 10.66wt%, and the content of CaO is about 40.62wt%; The main components in the spent FCC catalyst are: SiO 2 The content is about 37.65wt%, Al 2 o 3 The content of is about 55.29wt%, and the particle size of the spent FCC catalyst is less than 0.2mm.

[0045] Its preparation method comprises the following steps:

[0046] S1. Mix 200g of FCC waste catalyst with 300g of sintering red mud powder to obtain a mixed powdery material A with a calcium-aluminum molar ratio of 0.78;

[0047] S2. Add 211.07g of silica fume to the mixed powdery material A obtained in step S1, SiO in the silica fume 2 The content of is about 93.33%, and the mixed powdery material B with a silicon-aluminum molar ratio of 2 is obtained;

Embodiment 2

[0052] A geopolymer prepared by coupling FCC waste catalyst and sintering red mud, wherein the composition of the FCC waste catalyst and sintering red mud is roughly the same as in Example 1, and the preparation method is as follows:

[0053] S1. Mix 250g of FCC waste catalyst with 250g of sintering red mud powder to obtain a mixed powdery material A with a molar ratio of calcium to aluminum of 0.56;

[0054] S2. Add 258.45g of silica fume to the mixed powdery material A obtained in step S1, SiO in the silica fume 2 The content of is about 93.33%, and the mixed powdery material B with a silicon-aluminum molar ratio of 2 is obtained;

[0055] S3. take by weighing 86.56g sodium hydroxide and 412.17g water glass, add sodium hydroxide in water glass under stirring, until sodium hydroxide dissolves completely, obtain the compound alkali activator that modulus is 1.2, stand-by;

[0056] Then mix the composite base activator (379.23g) with a mass ratio of 1:2 and the mixed powdery m...

Embodiment 3

[0059] A geopolymer prepared by coupling FCC waste catalyst and sintering red mud, wherein the composition of the FCC waste catalyst and sintering red mud is roughly the same as in Example 1, and the preparation method is as follows:

[0060] S1. Mix 300g of FCC waste catalyst with 200g of sintering red mud powder to obtain a mixed powdery material A with a molar ratio of calcium to aluminum of 0.40;

[0061] S2. Add 305.83g of silica fume to the mixed powdery material A obtained in step S1, SiO in the silica fume 2 The content of is about 93.33%, and the mixed powdery material B with a silicon-aluminum molar ratio of 2 is obtained;

[0062] S3. take by weighing 86.56g sodium hydroxide and 412.17g water glass, add sodium hydroxide in water glass under stirring, until sodium hydroxide dissolves completely, obtain the compound alkali activator that modulus is 1.2, stand-by;

[0063] Then mix the composite base activator (402.92g) with a mass ratio of 1:2 and the mixed powdery m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com