Nano composite material, glassy carbon composite electrode, manufacturing methods of nano composite material and glassy carbon composite electrode, and electrochemical sensor

A technology of nanocomposite materials and composite electrodes, which is applied in the field of electrode materials and can solve problems such as low sensitivity, cumbersome sample processing, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

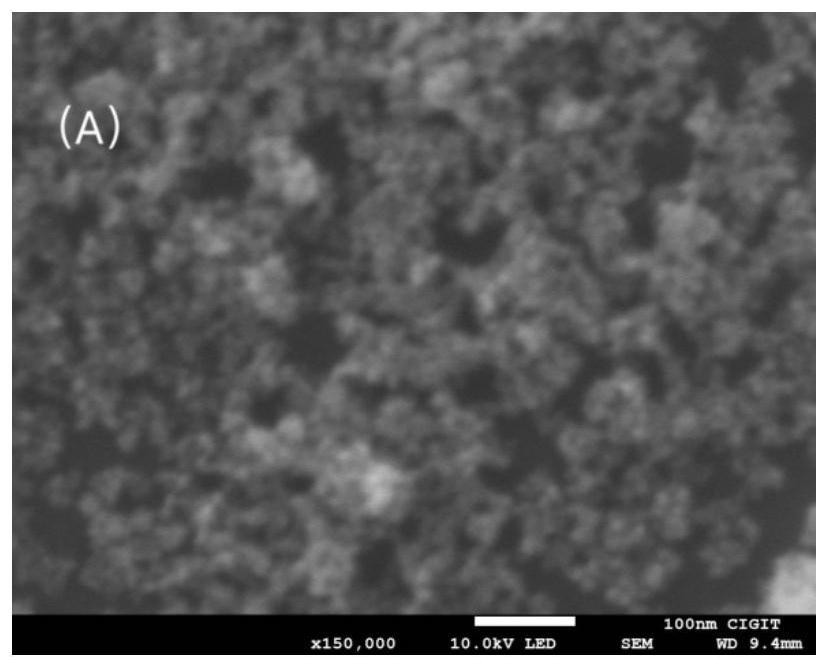

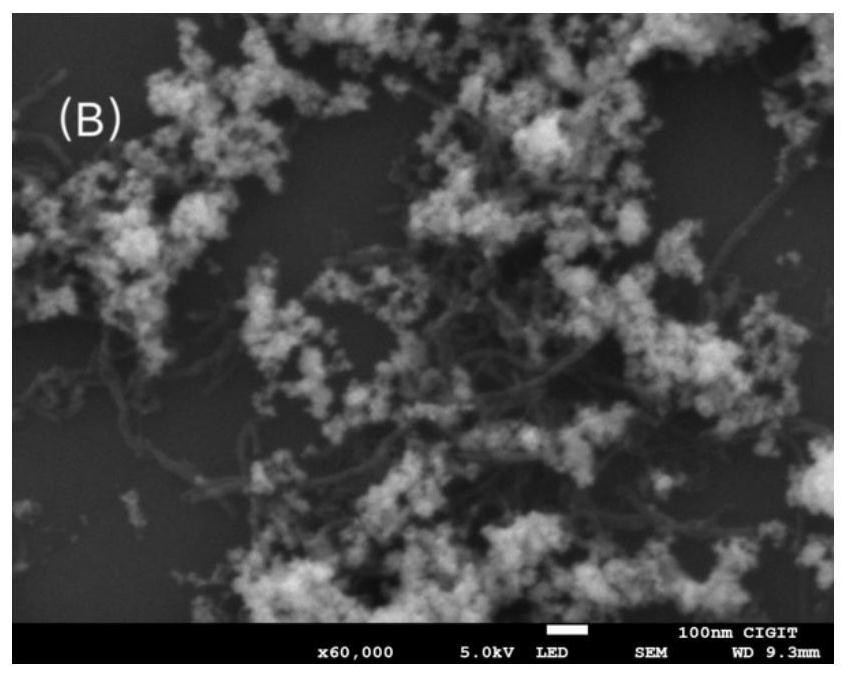

[0048] Pretreatment of MWNTs

[0049] Take 2 g of MWNTs and put them in the mixed acid mixed with nitric acid and hydrochloric acid with a ratio of 1:3 to reflux for 24 hours to prepare a sample solution, add excess water to the sample solution for repeated washing until the pH value of the sample solution is 7, and then The sample solution was dried in an oven to obtain acidified MWNTs.

[0050] Among them, MWNTs are multi-walled carbon nanotubes, which have the advantages of very high stability, good current carrying capacity, and excellent electronic behavior. The acidification of MWNTs is firstly to remove impurities in MWNTs, and secondly to introduce carboxyl groups (-COOH) on MWNTs, and then form carboxyl functionalized multi-walled carbon nanotubes (MWCNTs-COOH), which can enhance their electron transfer. ability, the electron transfer between the electrode and the electrolyte will be easier, and the dispersibility in aqueous solution will be improved due to the intro...

Embodiment 2

[0062] Pretreatment of MWNTs

[0063] Take 2 g of MWNTs and place them in a mixed acid mixed with nitric acid and hydrochloric acid at a ratio of 1:3 to reflux for 26 hours to prepare a sample solution. Add excess water to the sample solution for repeated washing until the pH value of the sample solution is 7, and then The sample solution was dried in an oven to obtain acidified MWNTs.

[0064] CeO 2 preparation of

[0065] CeO was treated by hydrothermal method 2 For preparation, 5.5gCe(NO 3 )·6H 2 O was dissolved in 100 g of pure water, stirred by magnetic force at room temperature, and NH was added during the stirring process. 4 OH solution until the pH value in the solution was 11 to obtain a gel mixture, followed by washing, drying and calcination to obtain CeO 2 .

[0066] Specifically, the obtained gel mixture is dried in an oven at a temperature of 130° C. for 12.5 hours, and then calcined in a muffle furnace at a high temperature of 560° C. for 4.5 hours.

[0...

Embodiment 3

[0075] Pretreatment of MWNTs

[0076]Take 2 g of MWNTs and place them in a mixed acid mixed with nitric acid and hydrochloric acid at a ratio of 1:3 to reflux for 24.5 hours to prepare a sample solution. Add excess water to the sample solution for repeated washing until the pH value of the sample solution is 7. Afterwards, the sample solution was dried in an oven to obtain acidified MWNTs.

[0077] CeO 2 preparation of

[0078] CeO was treated by hydrothermal method 2 For preparation, 4.8gCe(NO 3 )·6H 2 O was dissolved in 100 g of pure water, stirred by magnetic force at room temperature, and NH was added during the stirring process. 4 OH solution until the pH value in the solution was 11 to obtain a gel mixture, followed by washing, drying and calcination to obtain CeO 2 .

[0079] Specifically, the obtained gel mixture was dried in an oven at a temperature of 122° C. for 11.8 hours, and then calcined in a muffle furnace at a high temperature of 546° C. for 3.8 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com