A kind of garnet type solid-state composite electrolyte, preparation method and application

A composite electrolyte, garnet-type technology, applied in the field of lithium battery electrolyte materials, can solve the problems of unreached electrical conductivity, high interface impedance, cumbersome preparation methods, etc., to avoid lithium dendrites, good high temperature resistance, and easy to obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

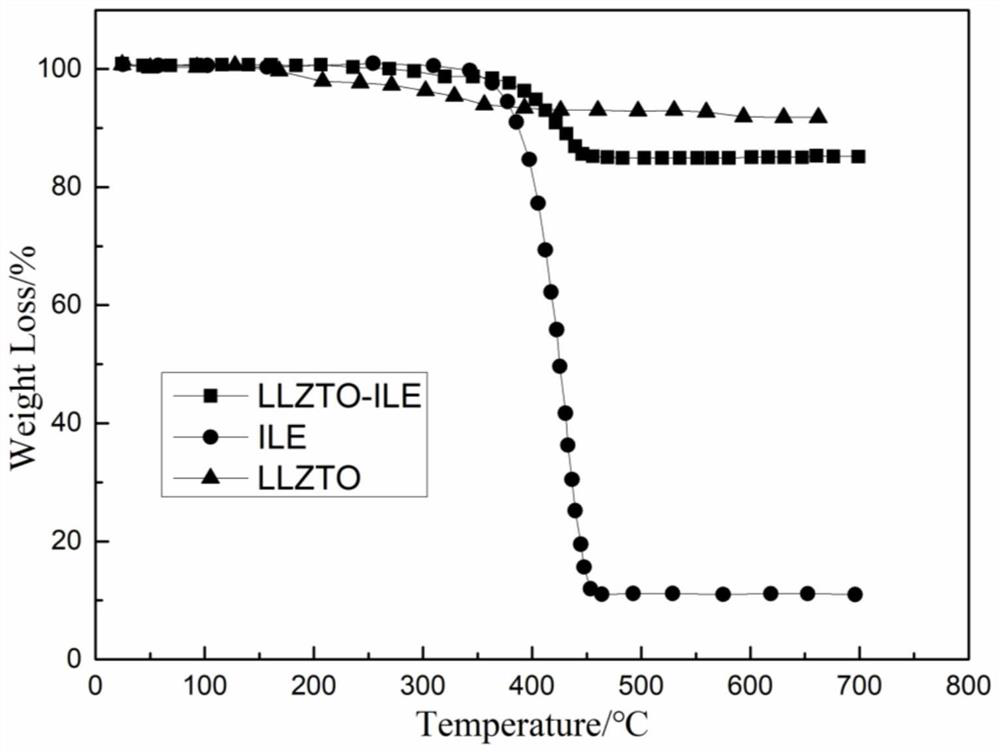

[0042] (1) In a glove box filled with argon gas with a purity of ≥99% and a moisture content of less than 0.1ppm, weigh 2.2966g of lithium bistrifluoromethanesulfonylimide to 13.9g of N-methyl, propylpyrrolidine bistris In the fluoromethanesulfonylimide salt, stir until the lithium salt is completely dissolved to obtain an ionic liquid electrolyte;

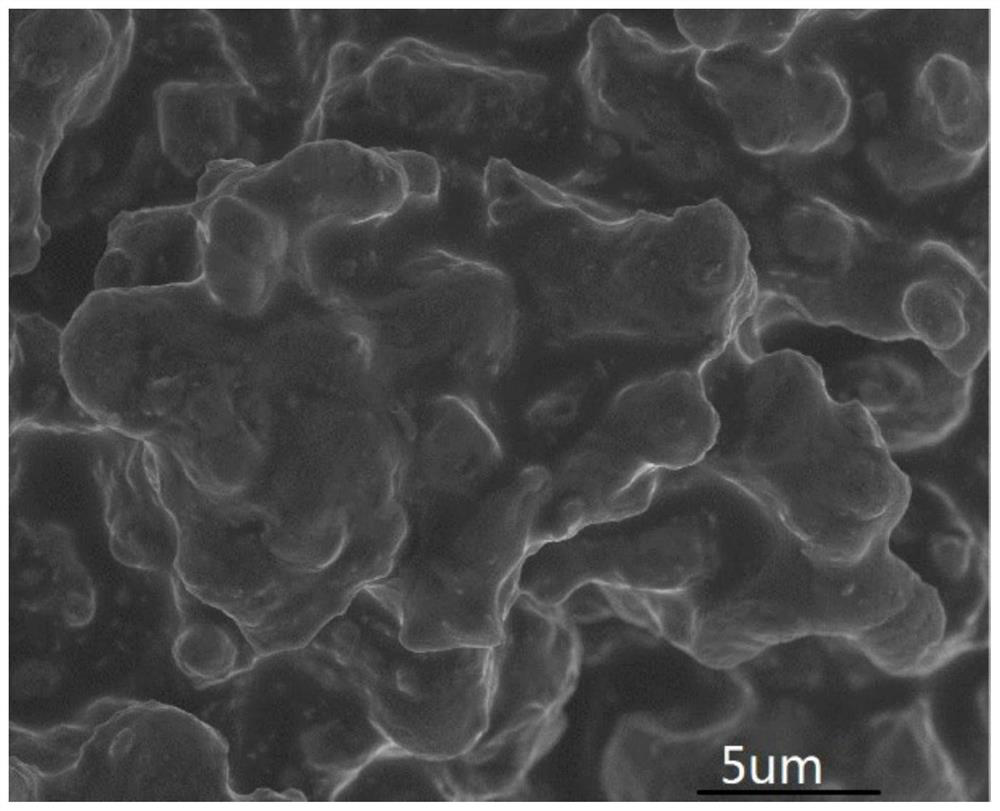

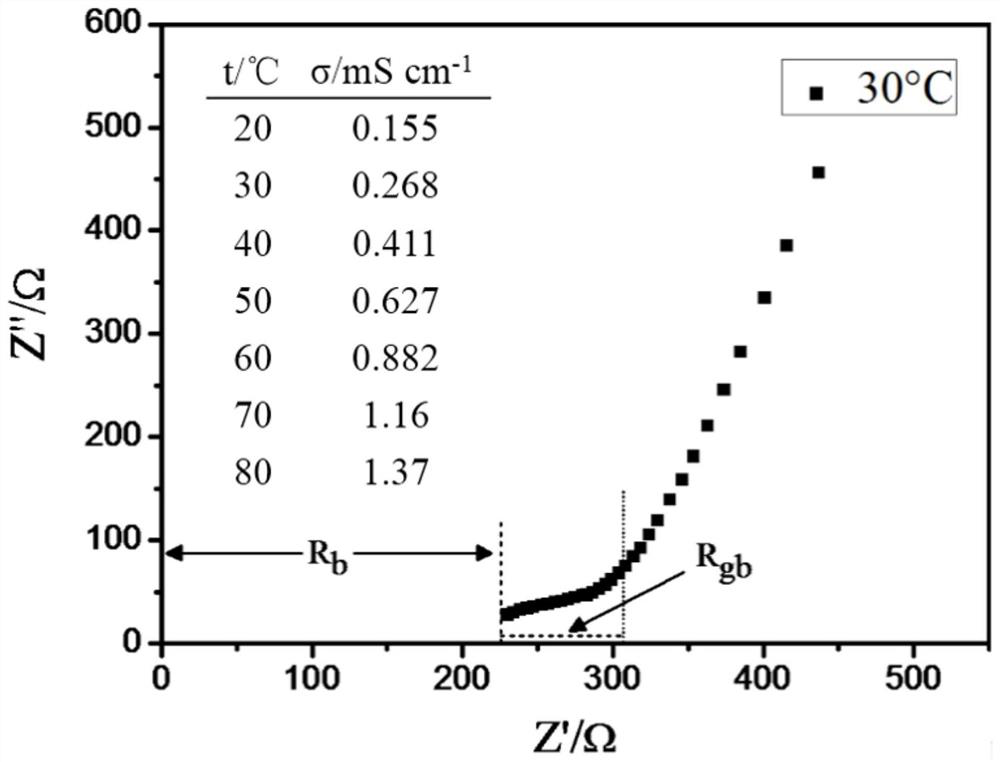

[0043] (2) Weigh 1g of garnet-type oxide electrolyte Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Put it into the ball mill jar, then add 0.25g of ionic liquid electrolyte, seal the ball mill jar and mill for 4h, the speed is 300r min -1 Take out the material after ball milling to obtain a garnet-type solid-state composite electrolyte according to the present invention;

[0044] LiFePO 4 As an active electrode material, it is assembled with the garnet-type solid-state composite electrolyte prepared in this example to form a CR2025 lithium secondary battery, and then the electrochemical performance test is performed under constant current ...

Embodiment 2

[0055] (1) In a glove box filled with argon gas with a purity of ≥99% and a moisture content of less than 0.1ppm, weigh 2.8708g of lithium bistrifluoromethanesulfonylimide to 13.9g of N-methyl, propylpyrrolidine bistrifluoro In the methanesulfonylimide salt, stir until the lithium salt is completely dissolved to obtain an ionic liquid electrolyte;

[0056] (2) Weigh 1g of garnet-type oxide electrolyte Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Put it into the ball mill jar, then add 0.25g of ionic liquid electrolyte, seal the ball mill jar and mill for 4h, the speed is 300r min -1 Take out the material after ball milling to obtain a garnet-type solid-state composite electrolyte according to the present invention;

[0057] LiFePO 4 As an active electrode material, it is assembled with the garnet-type solid-state composite electrolyte prepared in this example to form a CR2025 lithium secondary battery, and then the electrochemical performance test is performed under constant current c...

Embodiment 3

[0068] (1) In a glove box filled with argon gas with a purity of ≥99% and a moisture content of less than 0.1ppm, weigh 3.4450g lithium bistrifluoromethanesulfonylimide to 13.9g N-methyl, propylpyrrolidine bistrifluoro In the methanesulfonylimide salt, stir until the lithium salt is completely dissolved to obtain an ionic liquid electrolyte;

[0069] (2) Weigh 1g of garnet-type oxide electrolyte Li 6.5 La 3 Zr 1.4 Ta 0.6 o 12 Put it into the ball mill jar, then add 0.25g of ionic liquid electrolyte, seal the ball mill jar and mill for 4h, the speed is 300r min -1 Take out the material after ball milling to obtain a garnet-type solid-state composite electrolyte according to the present invention;

[0070] LiFePO 4 As an active electrode material, it is assembled with the garnet-type solid-state composite electrolyte prepared in this example to form a CR2025 lithium secondary battery, and then the electrochemical performance test is performed under constant current charge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com