Degradable artificial bone particles with core-shell structure and preparation method thereof

A technology of core-shell structure and artificial bone, which can be applied to household appliances, ceramic products, and other household appliances, etc., and can solve problems such as difficulty in combining multiple properties, slow degradation rate, and excessive degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0118] The preparation method of the present disclosure is not limited thereto. In some examples, the preparation method of the present disclosure can be used to prepare artificial bone particles with a core-shell structure of three or more layers. For example, the above-mentioned artificial bone particles with a three-layer structure including a single-layer coating layer (referred to as three-layer artificial bone particles) or artificial bone particles with a multi-layer structure including multiple layers of coating layers (referred to as multi-layer artificial bone particles).

[0119] In some examples, the preparation method of the three-layer artificial bone particle can refer to the steps of the above-mentioned double-layer artificial bone particle. The difference is that the third foaming slurry needs to be obtained when preparing the three-layer artificial bone particles. The obtaining of the third foaming slurry can refer to the method for obtaining the first foamin...

Embodiment 1

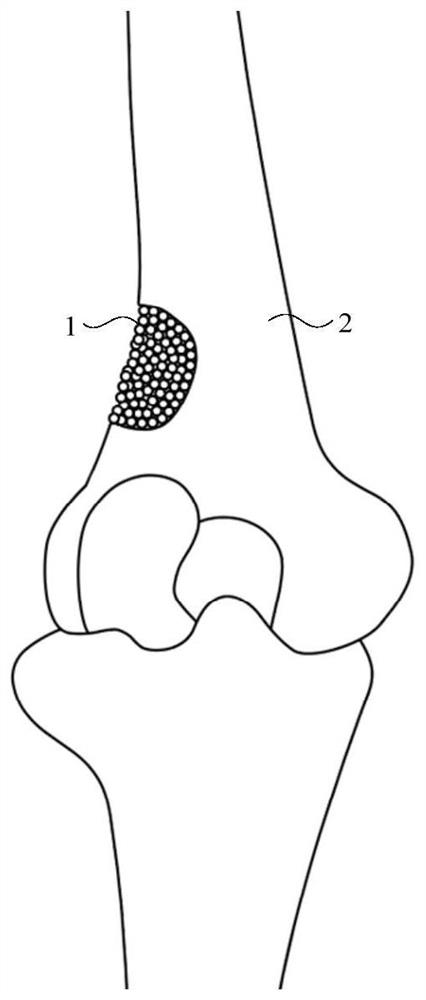

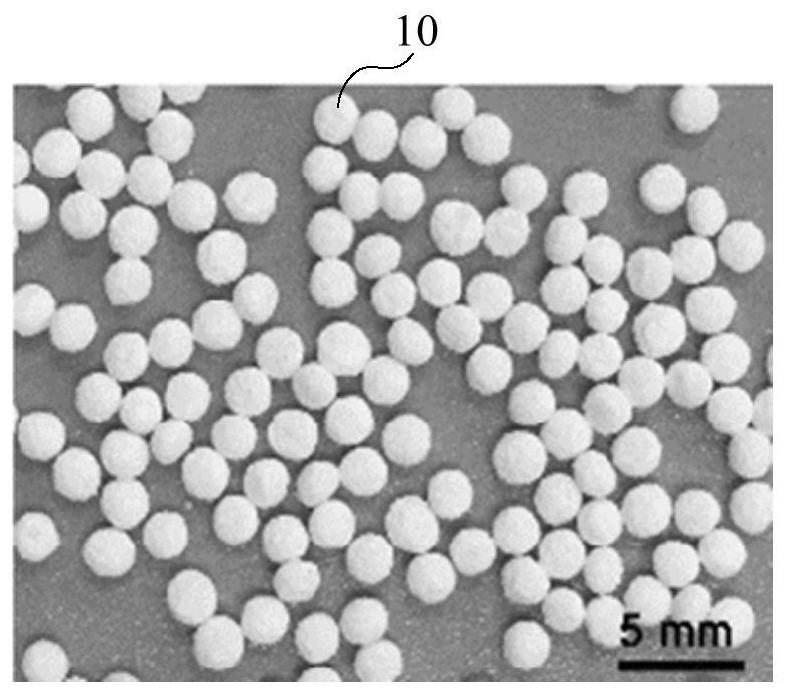

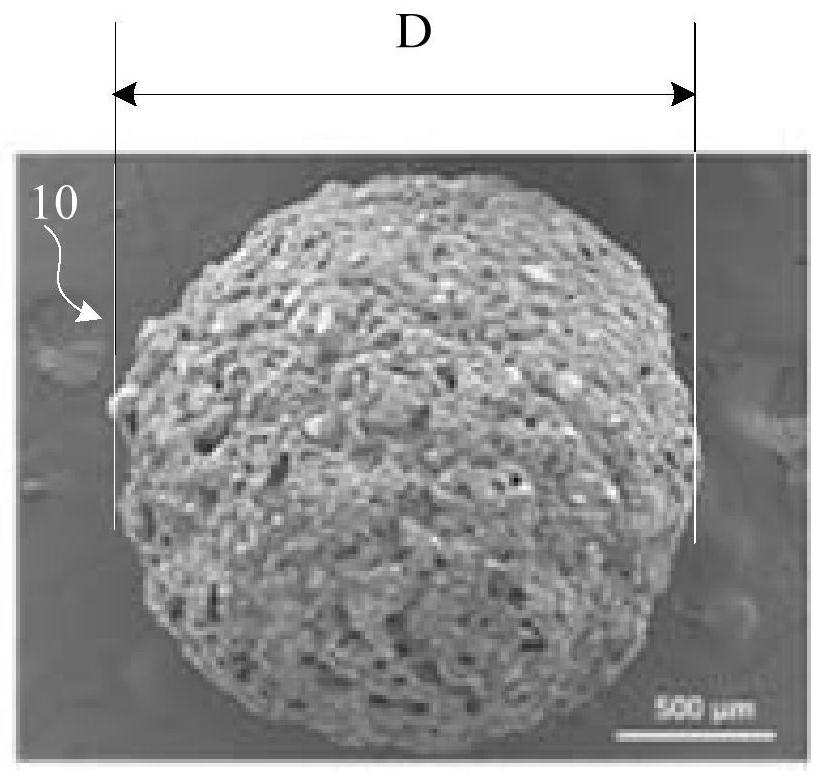

[0122] In Example 1, a degradable artificial bone particle having a BCP outer shell layer and an HA inner core layer was prepared.

[0123] In Example 1, 4g of BCP powder and 4g of HA powder were weighed and poured into two 250mL glass beakers respectively, 50mL of deionized water was added, and fully stirred with a glass rod. Move the evenly stirred slurry to a numerically controlled ultrasonic cleaner for ultrasonic vibration for 10 min, then transfer the slurry to a 50 mL centrifuge tube, and centrifuge for 3 min at a speed of 3000 r / min in a low-speed centrifuge.

[0124] In Example 1, the supernatant in the centrifuge tube was removed, and the ceramic precipitate was put into a 250mL beaker, and a volume of 10mL of sodium alginate (Na Alg) with a mass fraction of 6wt%, and a volume of 2mL with a mass fraction of 2wt% methyl cellulose (MC), mixed evenly with an emulsifying homogenizer. Then add a volume of 1.5 mL of 30% H 2 o 2 and 20 mL of deionized water, using a high...

Embodiment 2

[0130] In Example 2, a degradable artificial bone particle having a β-TCP outer shell layer and an HA inner core layer was prepared. The preparation method refers to Example 1. The difference between the preparation method in Example 2 and the preparation method in Example 1 is that the powders selected in Example 2 are 4g HA powder and 4g β-TCP powder. In addition, after adding H 2 o 2 When fully stirred with deionized water using a high-speed stirrer, the deionized water is 15mL. The β-TCP foaming slurry was extruded from the shell channel of the coaxial double-layer needle. Extrude the HA foaming slurry from the core channel of the coaxial double-layer needle.

[0131] In Example 2, the outer shell layer of the degradable artificial bone particles in which β-TCP is the outer shell layer and HA is the inner core layer has strong angiogenesis ability, and the inner core layer degrades slowly to provide mechanical support. It is suitable for the repair of femoral head nec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com